- Product Details

- {{item.text}}

Quick Details

-

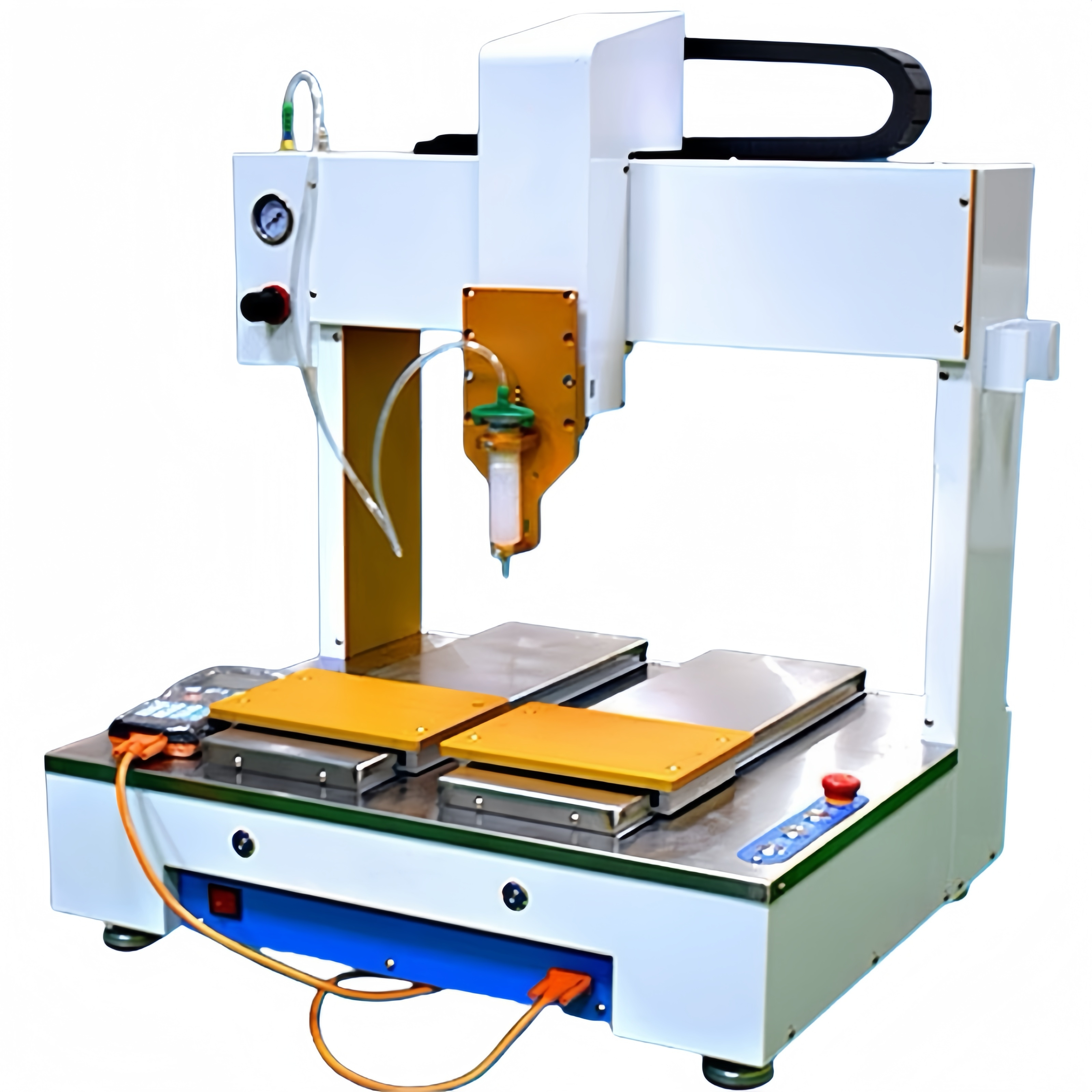

Dimension(L*W*H):

-

637X560X820mm

-

Weight:

-

280 KG

Quick Details

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TES

-

Dimension(L*W*H):

-

637X560X820mm

-

Weight:

-

280 KG

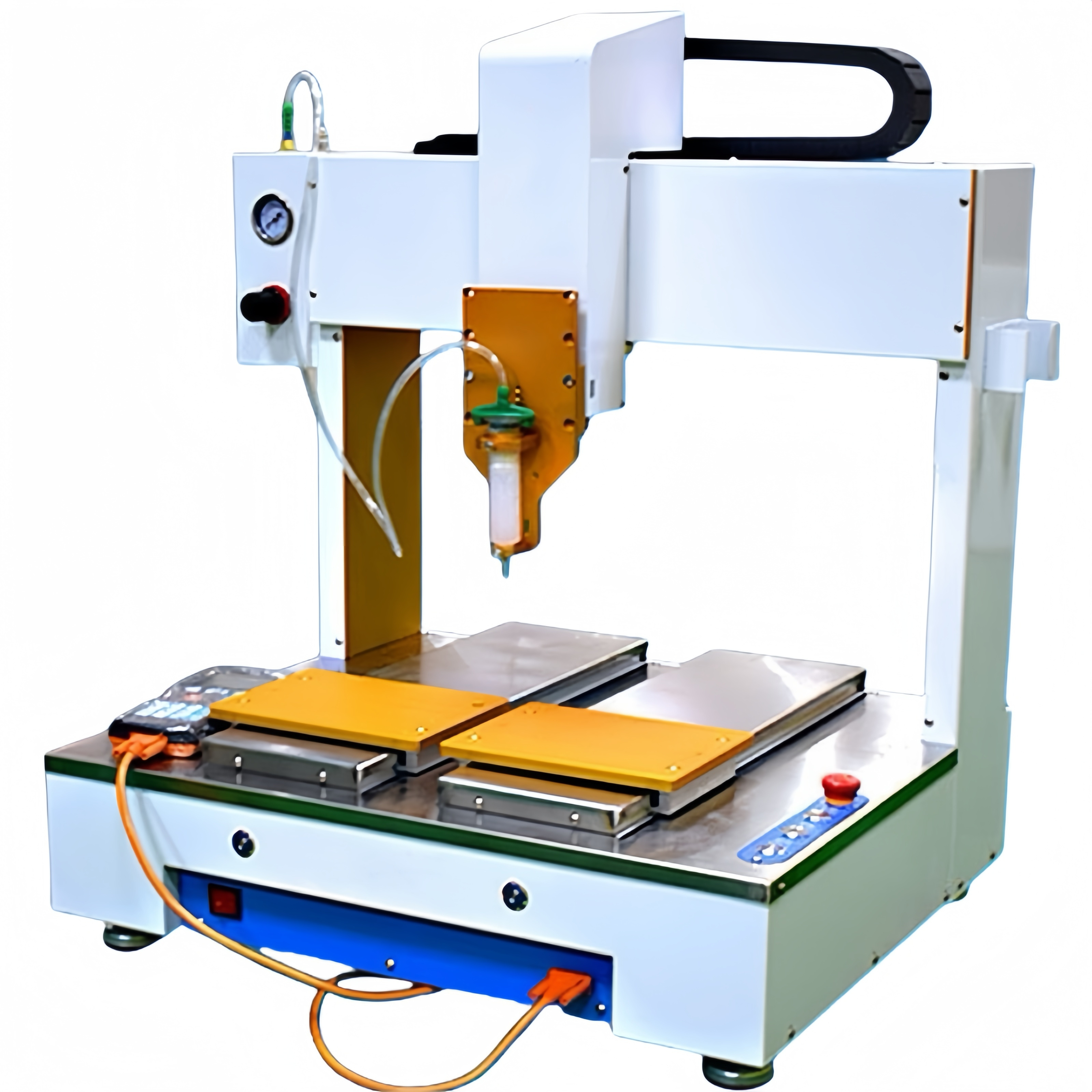

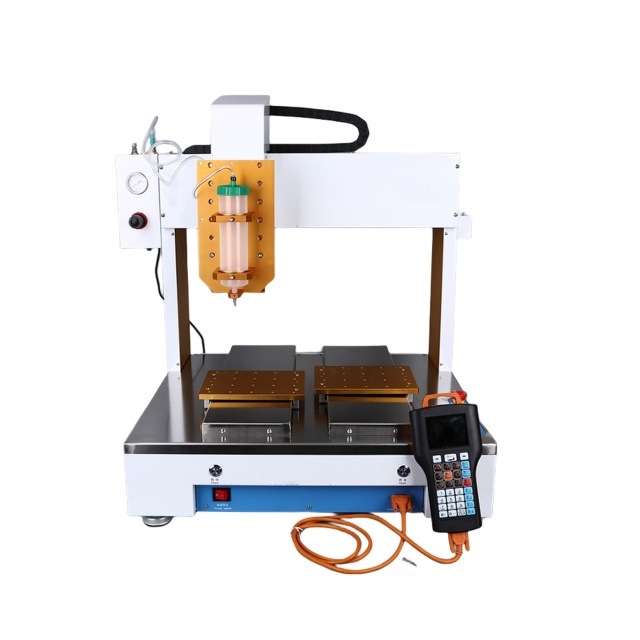

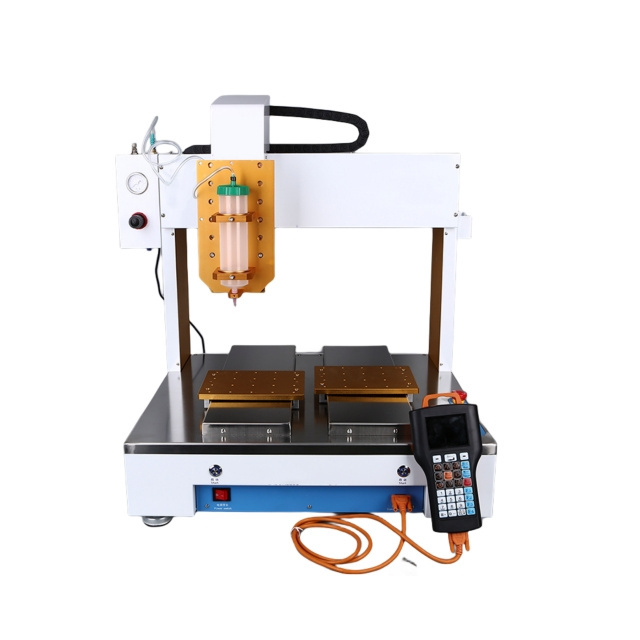

Three-axis dispensing machine fully automatic eyelash dispensing equipment hot melt silicone AB glue uv glue dispensing machine

Product characteristics:

1, high-speed sheet metal structure, stainless steel panel beautiful appearance, strong consistency; 2, the mechanical parts are processed by CNC to ensure the precision and consistency of the parts; 3, standard assembly process, strict machine calibration standards to ensure the accuracy of the machine; 4, high standard core components, stable and reliable quality, durable: high precision stepper motor, brand synchronous belt, Taiwan silver linear guide rail; 5, high-speed operation, smooth and smooth, low noise; 6, the use of synchronous pulley and motor special assembly process, with... The synchronization belt of the process completely solves the problem of tension and loosening of the synchronization belt after long-term use; 7, modular assembly process, each key component and key position can be disassembled separately, accidental damage parts can be quickly replaced; 8, the use of. Brand folding tape shielded cable, so that the operation of the machine more worry, from the root to eliminate the broken line, lack of equal hidden dangers.

Hot Searches