- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3830x2450x2990

-

Weight:

-

13000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Custom Made

-

Power(W):

-

15KW

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE,ISO

-

Marketing Type:

-

New Product 2020

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIXER

-

Voltage:

-

220V/380V/415V/440V/480V

-

Dimension(L*W*H):

-

3830x2450x2990

-

Weight:

-

13000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Custom Made

-

Power(W):

-

15KW

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE,ISO

-

Marketing Type:

-

New Product 2020

Product Description

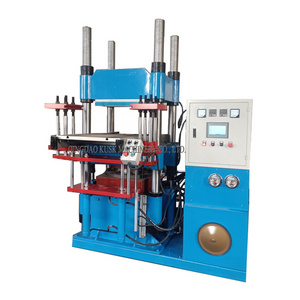

vacuum rubber compression stopper molding press machine

APPLICATIONS:

Ideal for the production of making rubber gaskets, O-rings, keyboards, medical stoppers, medical rubber products, seal, wipers scraping head, sports ,rubbe seals,etc.

REMARKABLE FEATURES:

· The vacuum suction hood provides highly efficient vacuum suction effect for the entire mold inside the working platen, suction speed of 700HG/2 sec. The unit offers simplified construction, easy to operate and maintain, with fast mold change.

· Integrated hydraulic circuit provide various pipe functions on the circuit boards, reducing piping to a minimum. The oil cooler ensures long service life of the circuit valve.

· The motion time, traverse and number of motions can be conveniently set on the control panel to meet product variations, ensuring production quality.

· Combines two molding units in one machine, which can be operated separately.

· While in vulcanization molding operations, the hydraulic pump motor can be set for running, or stopped for power saving.

· The electric system is controlled by the PLC controller, allowing for easy operation and accurate adjustment. An emergency switch provides added safety for the mold and the operator.

Specification

|

Model

|

|

YH-HV80T-2

|

YH-HV150T-2

|

YH-HL200T-2

|

YH-HV250T-2

|

YH-HV300T-2

|

|

Clamping Force

|

TON

|

80

|

150

|

200

|

250

|

300

|

|

Plate Size

|

mm

|

380×420

|

450×450

|

500×550

|

550×550

|

650×650

|

|

Piston Stroke

|

mm

|

380

|

345

|

380

|

380

|

380

|

|

Heating Capacity

|

kw

|

9

|

9

|

13.5

|

20.4

|

20.4

|

|

Pump Motor

|

kw

|

5.5

|

7.5

|

7.5

|

11

|

15

|

|

Piston Diameter

|

mm

|

230

|

356

|

495

|

406

|

430

|

|

Max Mold Size L×W×H

|

mm

|

340×380 ×180

|

410×410 ×120

|

510×510 ×200

|

510×510 ×200

|

610×610 ×175

|

|

Machine Dimensions

|

mm

|

2850×1625 ×2610

|

3150×1640×2550

|

3650×1800×3090

|

3650×1800×3090

|

3830×2450×2990

|

|

Machine Weight

|

kg

|

6500

|

7200

|

9300

|

11000

|

13000

|

|

Model

|

|

YH-HV80T

|

YH-HV150T

|

YM-HL200T

|

YM-HV250T

|

YM-HV300T

|

YM-HV400T

|

YM-HV600T

|

|

Clamping Force

|

TON

|

80

|

150

|

200

|

250

|

300

|

400

|

600

|

|

Plate Size

|

mm

|

380×420

|

450×450

|

500×550

|

500×550

|

650×650

|

800×800

|

1000×1000

|

|

Piston Stroke

|

mm

|

380

|

345

|

380

|

380

|

380

|

450

|

520

|

|

Heating Capacity

|

kw

|

9

|

9

|

13.5

|

20.4

|

20.4

|

24

|

42

|

|

Pump Motor

|

kw

|

4

|

5.5

|

7.5

|

11

|

15

|

15

|

18.5

|

|

Piston Diameter

|

mm

|

230

|

305

|

356

|

406

|

430

|

500

|

610

|

|

Max Mold Size L×W×H

|

mm

|

340×380

×180

|

410×410

×200

|

510×510

×200

|

510×510

×200

|

610×610

×175

|

760×760

×200

|

960×960

×305

|

|

Machine Dimensions

|

mm

|

1720×1625

×2610

|

1875×1640

×2550

|

2120×1800

×3090

|

2120×1800

×3090

|

2210×2200

×2990

|

2440×2190

×3430

|

3100×2450

×4060

|

|

Machine Weight

|

kg

|

3000

|

3200

|

5200

|

6200

|

6800

|

12500

|

14000

|

Packaging & Shipping

Hot Searches