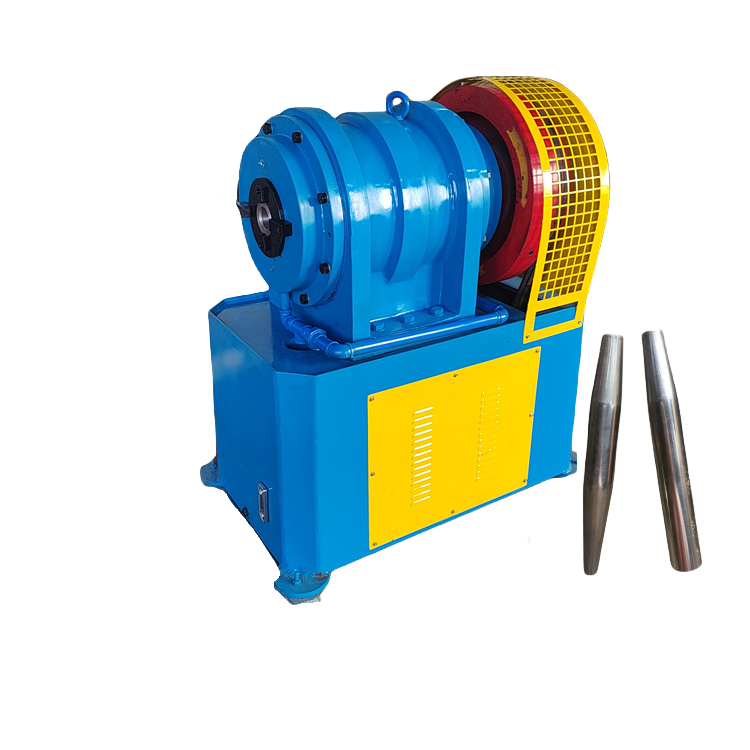

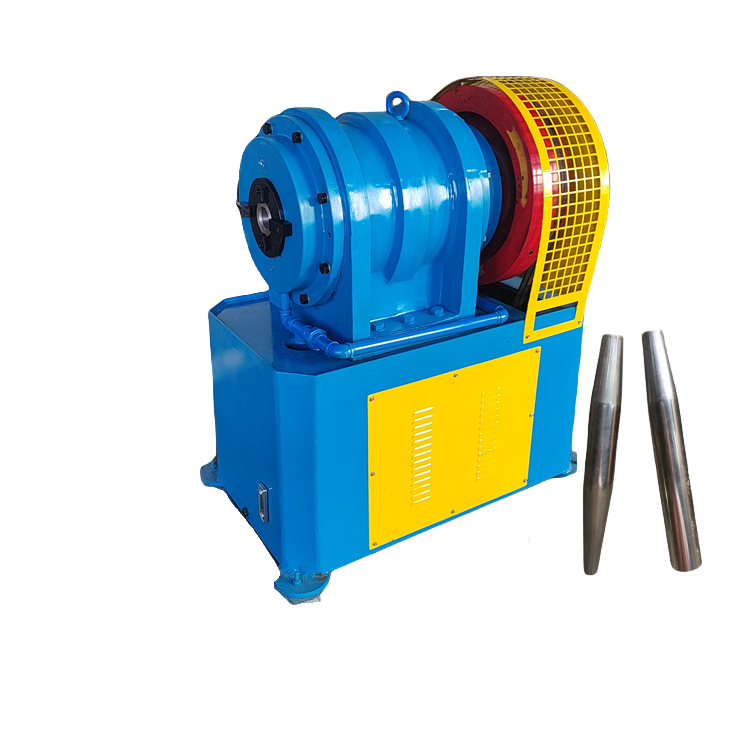

- Product Details

- {{item.text}}

Quick Details

-

Max. Tube Contracting Length (mm):

-

400

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOJOSOCO

-

Year:

-

2023

-

Power (kW):

-

5.5

-

Weight (KG):

-

2000

-

Product name:

-

Pipe Forming Machine

-

Function:

-

Shrinking

-

After-sales Service Provided:

-

Online Support

-

Control System:

-

Hydralic

-

Application:

-

Metal Pipe Processing

-

Keyword:

-

Tapper Forming Machine

-

Name:

-

Second Hand Hydraulic Hose Crimper

-

Type:

-

Automatic Tube Shrink Machine

-

Key words:

-

Sealing Machine Automatic

-

Usage:

-

Punching Tube

Quick Details

-

Max.Shrinking Capacity (Thickness)(mm):

-

5 mm

-

Max.Shrinking Capacity (Diameter)(mm):

-

40 mm

-

Tube Contracting Cycle (s):

-

5 - 8

-

Max. Tube Contracting Length (mm):

-

400

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOJOSOCO

-

Year:

-

2023

-

Power (kW):

-

5.5

-

Weight (KG):

-

2000

-

Product name:

-

Pipe Forming Machine

-

Function:

-

Shrinking

-

After-sales Service Provided:

-

Online Support

-

Control System:

-

Hydralic

-

Application:

-

Metal Pipe Processing

-

Keyword:

-

Tapper Forming Machine

-

Name:

-

Second Hand Hydraulic Hose Crimper

-

Type:

-

Automatic Tube Shrink Machine

-

Key words:

-

Sealing Machine Automatic

-

Usage:

-

Punching Tube

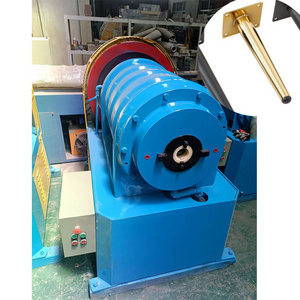

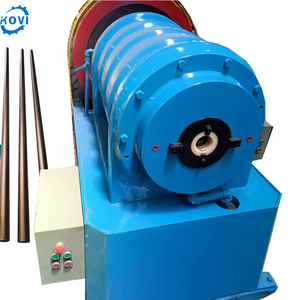

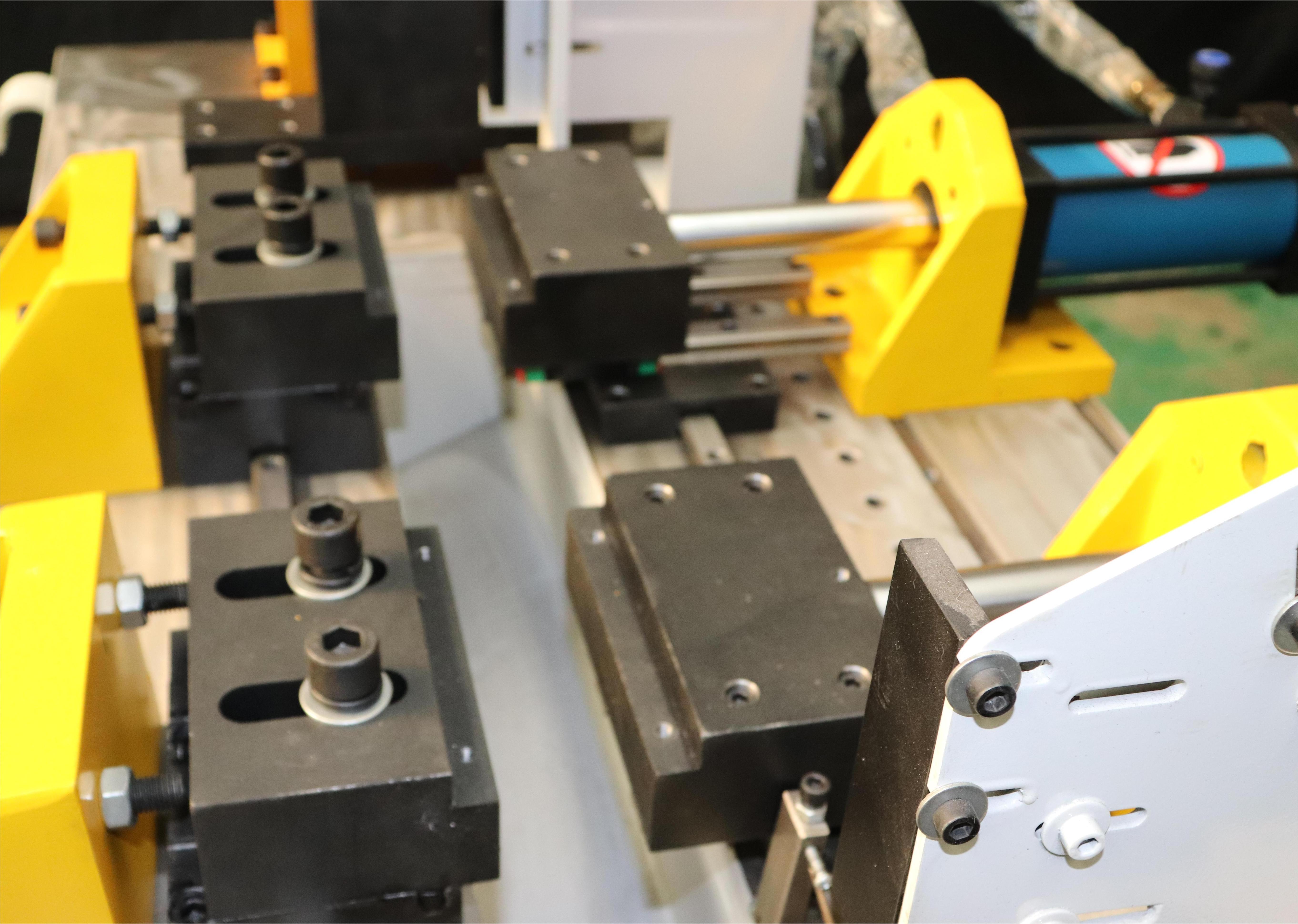

Product Overview

1. Operating system PLC control, hydraulic drive

2. Mobile foot switch with three functions: automatic, emergency stop, and continuous emergency stop, with high safety.

3. It can be processed in various ways such as shrinking, expanding, blunting, and bulging. The processing shapes include concave and convex joints, long, flat, square, extended, oblique, V-shaped, and openelbows, and the mold can be changed according to the user's processing of the product.

4. The mold replacement is simple and convenient for elastic production. The bed structure is compact and sturdy, using hydraulic power, stable operation, high yield, low vibration, and low noise. Can be used for pipe end reduction, expansion, bulging, upsetting, and other shapes of processing and forming. Suitable for processing and forming various shapes of pipe fittings, automotive oil pipes, air ducts, water pipes, and air conditioning pipe connections.

Video Description

Produck Paramenters

|

Name

|

TM-40NC/CNC

|

TM-60NC/CNC

|

TM-80NC/CNC

|

TM-100NC/CNC

|

|

|

Multi Station

|

Confirm according

to product requirements

|

Confirm according to product requirements

|

Confirm according to product requirements

|

Confirm according to product requirements

|

|

|

Maximum pipe diameter for shrink tubing

|

40mm*2mm

|

60mm*3mm

|

80mm*4mm

|

100mm*5mm

|

|

|

Maximum shrink tube stroke

|

100mm

can be customized

|

120mm

can be customized

|

140mm

can be customized

|

160mm

can be customized

|

|

|

Outer diameter of hydraulic cylinder

|

120mm

|

140mm

|

160mm

|

180mm

|

|

|

Outer diameter of main clamp hydraulic cylinder

|

110mm

|

130mm

|

150mm

|

170mm

|

|

|

power

|

4.0Kw

|

5.5Kw

|

7.5Kw

|

11Kw

|

|

|

Maximum working pressure

|

14Mpa

|

14Mpa

|

14Mpa

|

14Mpa

|

|

|

Weight

|

950Kg

|

1300Kg

|

1500Kg

|

2000Kg

|

|

|

Equipment appearance size

|

1800*1000*1200

|

2200*1200*1200

|

2400*1300*1300

|

2100*1500*1400

|

|

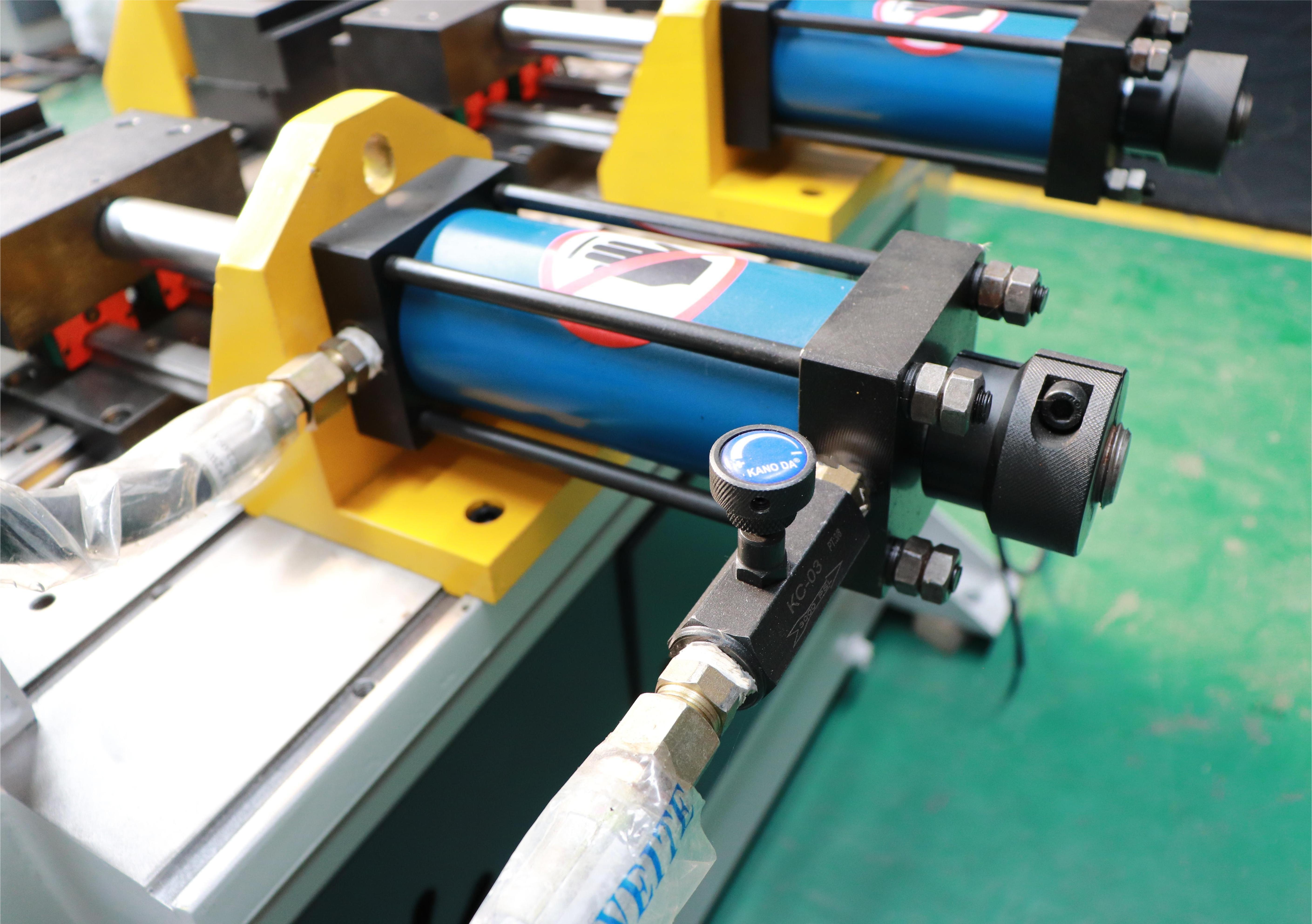

Double station oil cylinder mold replacement

Feeding method:

hydraulic cylinder

Hydraulic cooling method:

air-cooled machine

Our Services

Pre-service

1.We will help you confirm the model of our machine according to your offered pipe information.2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service:

1. Our machine is easy to use. Operation manual and teaching video will be sent out with machine. We also offer free training in our factory, the following is our training contents: Detailed function of our machine, 1 hour; NC control using, 0.5 hour; Tooling installation and adjustment, 0.5-1 hours; Maintenance and repair, 0.5-1 hours; Real operation according client products, 1-2 hours. During the training period,we offer free pick-up,hotel and food.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely. 3.Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service.

1.We will help you confirm the model of our machine according to your offered pipe information.2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service:

1. Our machine is easy to use. Operation manual and teaching video will be sent out with machine. We also offer free training in our factory, the following is our training contents: Detailed function of our machine, 1 hour; NC control using, 0.5 hour; Tooling installation and adjustment, 0.5-1 hours; Maintenance and repair, 0.5-1 hours; Real operation according client products, 1-2 hours. During the training period,we offer free pick-up,hotel and food.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely. 3.Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service.

Products Sample

Contact US

Our Advantages

Our strengths

1. Than fifteen-years factory

BOJOSOCO Machinery has been established for more than 15 years, and has been committed to product research and development, customer service as the core of the enterprise, to bring high-quality products for partners.

2. Product development

Focus on product research and development is the soul of BOJOSOCO machinery, accumulated decades of full experience, every year to develop a number of patented products, leading the industry.

3. Capacity guarantee

BOJOSOCO machinery a number of modern production workshops to ensure customer product supply

4. Product diversification

BOJOSOCO machinery co., LTD focuses on pipe equipment, including: pipe bending machine, tube chamfering machine, pipe cutting machine, pipe end forming machine, etc.

FAQ

1. How to choose the Pipe Bending Machine?

You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

2.Do you provide any training to make sure our user can operate the machine very well?

1)We will provide detailed video and instruction book for this machine;

2)We also offer training in our factory to all the clients,and we will arrange everything for you during these days in our city,

to make sure every client will be the expert in using our machine!

3. How long warranty can you provide?

Our machine warranty is one year,and we use all the stable compoenents with long working life! And we can also send our technician to do the after-sale service in client's factory!

4.What kind of solution you can offer to make sure your pipe bending machine can do our job?

1)We will help you confirm the model of our machine according to your offered pipe information.

2)Before you start the order for this big value machine,you can offer your workpiece drawing to us.

We can design the tooling to make your products in our workshop,after you are sure that the workpiece is good,then we can confirm the order finally.

3)You can visit us to check how to bend your product before you start the order.During this period, you can also learn how to use this machine well!

You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

2.Do you provide any training to make sure our user can operate the machine very well?

1)We will provide detailed video and instruction book for this machine;

2)We also offer training in our factory to all the clients,and we will arrange everything for you during these days in our city,

to make sure every client will be the expert in using our machine!

3. How long warranty can you provide?

Our machine warranty is one year,and we use all the stable compoenents with long working life! And we can also send our technician to do the after-sale service in client's factory!

4.What kind of solution you can offer to make sure your pipe bending machine can do our job?

1)We will help you confirm the model of our machine according to your offered pipe information.

2)Before you start the order for this big value machine,you can offer your workpiece drawing to us.

We can design the tooling to make your products in our workshop,after you are sure that the workpiece is good,then we can confirm the order finally.

3)You can visit us to check how to bend your product before you start the order.During this period, you can also learn how to use this machine well!

Hot Searches