- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Screw Diameter:

-

25/28/32mm

-

Platen Size:

-

520*370mm

-

Min. Mould Height:

-

100/140/160/200mm

-

Max. Mould Height:

-

280/320/340/380mm

-

System Pressure:

-

140kg/cm2

-

Pump Motor Power:

-

5.5(4)kw

-

Heater Power:

-

3.8kw

-

Machine Weight:

-

1.3 tons

-

Machine Dimensions:

-

1.5*0.9*2.3m

-

Opening Stroke:

-

180mm

-

Injection Rate:

-

58cm3/sec 73cm3/sec 95cm3/sec

-

Injection Weight:

-

49/60/79g

-

Certification:

-

CE ISO9001 Patent Certificate

-

Power:

-

9.3kw

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Screw Diameter:

-

25/28/32mm

-

Platen Size:

-

520*370mm

-

Min. Mould Height:

-

100/140/160/200mm

-

Max. Mould Height:

-

280/320/340/380mm

-

System Pressure:

-

140kg/cm2

-

Pump Motor Power:

-

5.5(4)kw

-

Heater Power:

-

3.8kw

-

Machine Weight:

-

1.3 tons

-

Machine Dimensions:

-

1.5*0.9*2.3m

-

Opening Stroke:

-

180mm

-

Injection Rate:

-

58cm3/sec 73cm3/sec 95cm3/sec

-

Injection Weight:

-

49/60/79g

-

Certification:

-

CE ISO9001 Patent Certificate

-

Power:

-

9.3kw

SANSHUN Machinery

is one of the top 10 Chinese injection moulding machinery manufacturer. We are manufacturing different types of injection moulding machines and range starts from 32 Ton to 2000 Ton. During the past 20 years, our machines had been exported to more than 60 countries.

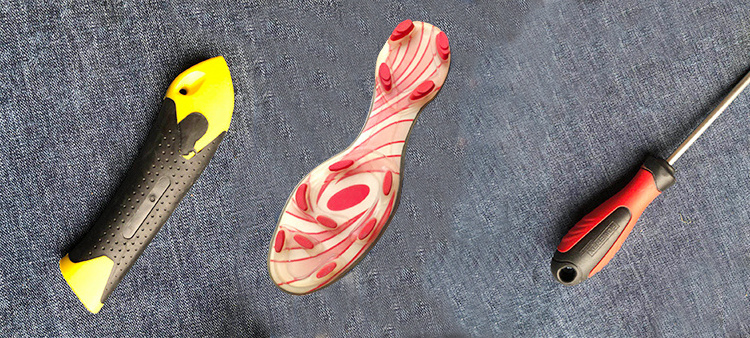

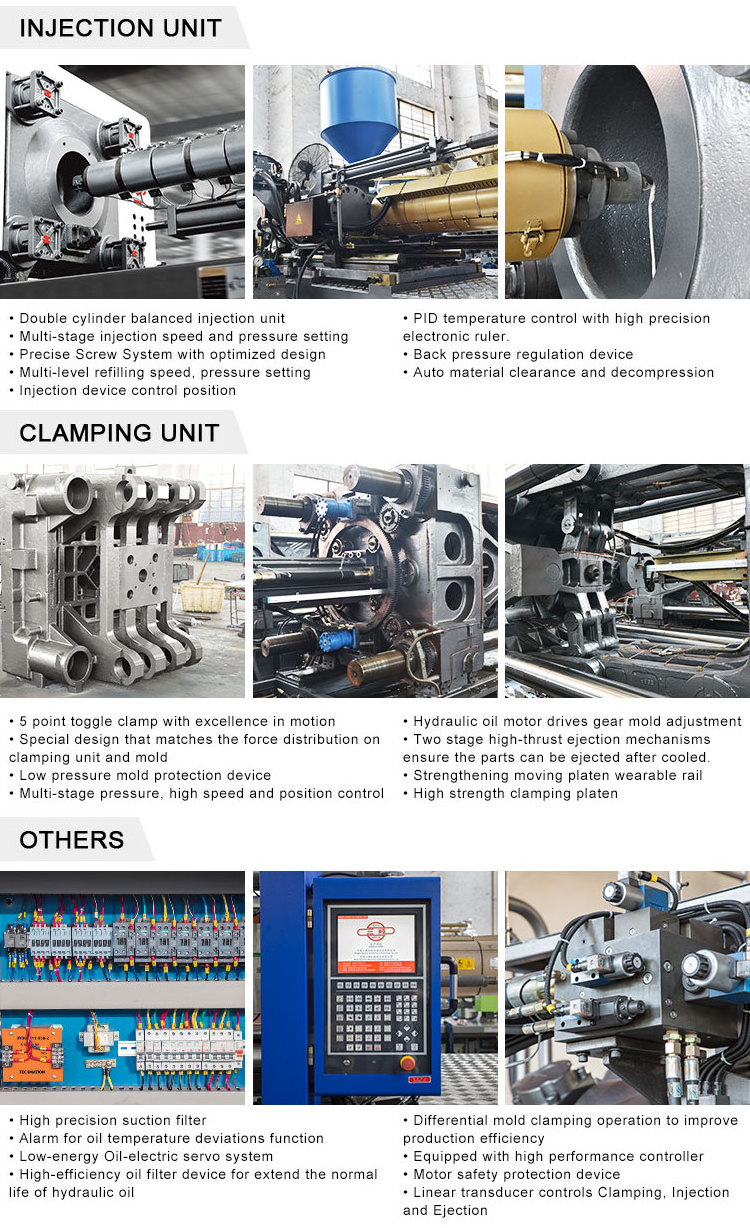

Characteristics

Sanshun Vertical Injection Molding Machine series for special plastic products and parts. Small volume, suitable for small and medium insert parts molding; High shot pressure, fast shot rate, the best choice for insert goods molding. Use famous brand accessories for electrical control and hydraulic system, low noise, precise, durable. Vertical screw injection system, multi-stage temperature control, multi-stage injection pressure and rate, back pressure adjustment, suitable for accurate plastic fittings molding

Advantages

Energy saving, environmental, low noise, quick response, high-efficiency, Shorter Cycle Time, Improve Production efficiency

Technical Parameters >>

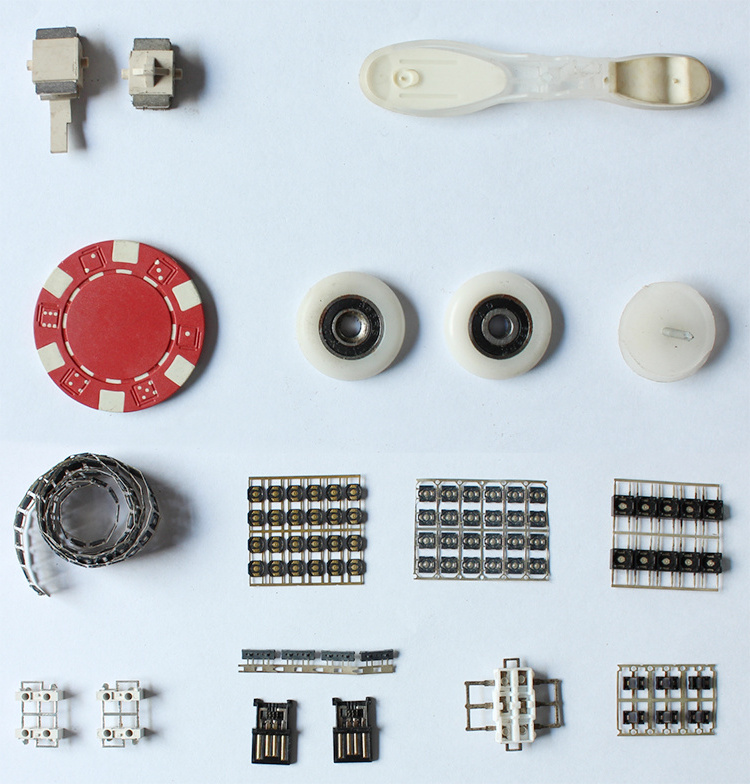

Application

Injection Molding Machines widely used in Automotive, Packaging, Electrical, Medical, Household and Appliance sectors. In particular, increasing demand in emerging economies fueled the growth of the injection molding machine market.