It has the unique way of splicing and high density correction institutions, what's more, the scoring machine play a very helpful

role for the further plastic and trimming. Quality of the product can be greatly improved, and the reduce a lot of unnecessary waste, thus educing costs.

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Strong quality gypsum board making machine

-

Capacity:

-

2-30 million m2 per year

-

Advantages:

-

Easy operation

-

Main process:

-

Drying system

-

Drying type:

-

Hot air or hot oil

-

Feature:

-

Save Energy Consumption

-

Fuel:

-

Coal, natural gas, diesel

-

Thickness:

-

7-15mm

-

Controlling system:

-

PLC+touch Screen

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Weight (KG):

-

200000

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

wuxing

-

Name:

-

Strong quality gypsum board making machine

-

Capacity:

-

2-30 million m2 per year

-

Advantages:

-

Easy operation

-

Main process:

-

Drying system

-

Drying type:

-

Hot air or hot oil

-

Feature:

-

Save Energy Consumption

-

Fuel:

-

Coal, natural gas, diesel

-

Thickness:

-

7-15mm

-

Controlling system:

-

PLC+touch Screen

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Product Description

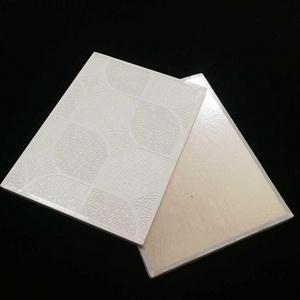

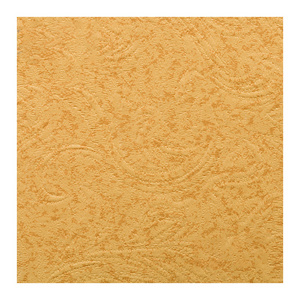

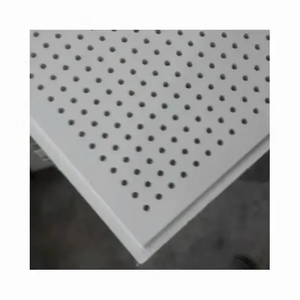

Paper faced gypsum board is made of (natural gypsum, desulfurization gypsum, phosphogypsum) as the main raw material, with appropriate additives and fibers as the core, and the special paper as the cover.

Paper supply system

Powder supply system

The system with a unique quantitative feeder as the core, so that the supply of gypsum powder is quite accurate, for a short time

to provide a great convenience for the operation of slurry adjustment, coupled with the pneumatic discharging device, so that the

supply of powder has a reliable guarantee.

to provide a great convenience for the operation of slurry adjustment, coupled with the pneumatic discharging device, so that the

supply of powder has a reliable guarantee.

Forming conveying system

Except the the conveyor, additional waste board cleaning machine, not only reduces the labor intensity, but also make the workshop

clean.

clean.

Heat supply systme

This system used organic carrier furnace(conduction oil furnace),it is a low-pressure high-temperature heating device, it is coal, natural gas or diesel as fuel. It is the preferred heating equipment of the gypsum board production line. In addition, the use of

flue gas heat exchanger to reduce energy consumption and reduce costs.

flue gas heat exchanger to reduce energy consumption and reduce costs.

Drying system

The drying system is the core set of production line,it directly affects the capacity and energy consumption of the production line.This system adopt the unique radiater structure, can control the temperature in each layer and each section, and also have new style air system, so that the temperature and humidity can adjust, which played a role in reducing energy consumption and easy to operate, it is the key to reducing the cost of production.

Fixed sizing system

The system with a unique overturn machine and stacker ,thus ending the history of manual work to cut-off the boards, reduce the costs of labors.

Control system

It has six parts, using computer programs control and use the converter solid-state relays, photoelecric sensors, non-contact

devices,ensure the reliable operation of the machine.

devices,ensure the reliable operation of the machine.

Process flow diagram

Specification

|

Annual output(sq.m)

|

2 million

|

5 million

|

8 million

|

10 million

|

20 million

|

30 Million

|

|

Speed of setting belt

|

V=4.0m/min

|

V=10.0m/min

|

V=16.0m/min

|

V=20.0m/min

|

V=40.0m/min

|

V=60.0m/min

|

|

Dryer |

V=0.75m/min |

V=1.0m/min |

V=1.33m/min |

V=1.25m/min |

V=2.0m/min |

V=2.5m/min |

|

|

Four Layers |

Six Layers |

Six Layers |

Eight Layers |

Ten Layers |

Twelve Layers |

Packing & Delivery

1. Suitable for long distance transportation

2. Small or key parts loaded in iron boxes

3. Iron boxes with welding

4. Naked

5. Please mark it in the sales contract for special package

2. Small or key parts loaded in iron boxes

3. Iron boxes with welding

4. Naked

5. Please mark it in the sales contract for special package

Certifications

Hot Searches