- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Donyue

-

Voltage:

-

380v,415v,220v or others

-

Dimension(L*W*H):

-

3200*2300*2750mm

-

Weight (KG):

-

8500 kg

-

Certification:

-

ISO,CE

-

color:

-

optional

-

Block Type:

-

Hollow Concrete Brick Machine

-

Model:

-

QT6-15

-

Pallet size:

-

1150x720MM

-

Vibration frequency:

-

2800-4500r/min

-

Vibration force:

-

100KN

-

Feature:

-

High Efficiency Low Cost

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, hollow brick, paver brick, solid brick

-

Brick Raw Material:

-

Cement,sand,aggregate,clay,fly ash,construction rubbish

-

Production Capacity (Pieces/8 hours):

-

1440-1080pcs/hour

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Donyue

-

Voltage:

-

380v,415v,220v or others

-

Dimension(L*W*H):

-

3200*2300*2750mm

-

Weight (KG):

-

8500 kg

-

Certification:

-

ISO,CE

-

color:

-

optional

-

Block Type:

-

Hollow Concrete Brick Machine

-

Model:

-

QT6-15

-

Pallet size:

-

1150x720MM

-

Vibration frequency:

-

2800-4500r/min

-

Vibration force:

-

100KN

-

Feature:

-

High Efficiency Low Cost

-

-

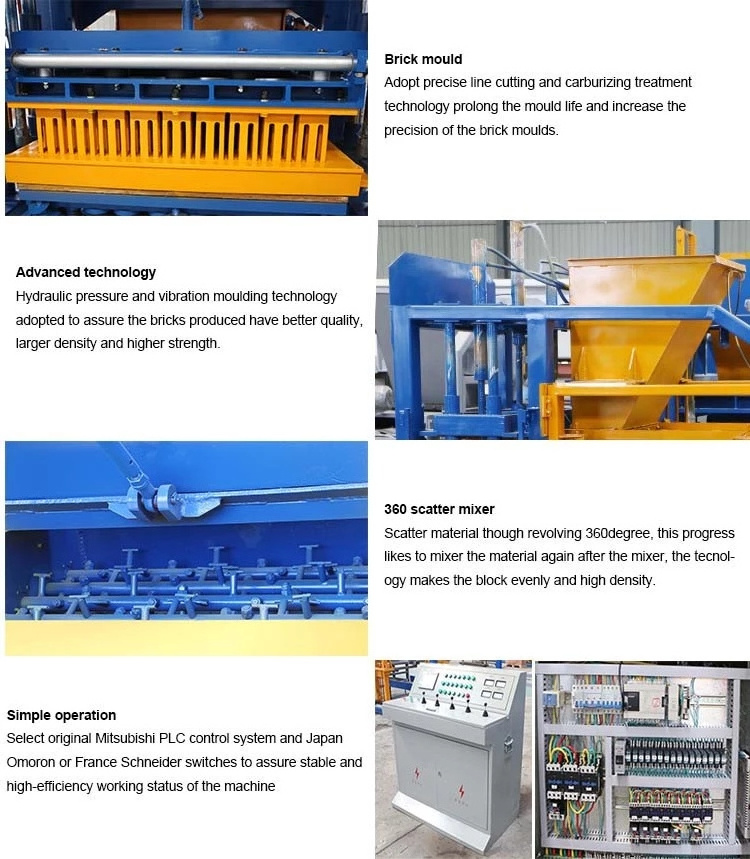

Use

Germany Siemens

PLC control system and Siemens Touch Screen, use

Schneider and Omron

relays and contactors:

Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

B. Visualization touch screen, with easy operation;

C. High-quality electrical components from Schneider and Omron; -

Use Frequency Conversional Control Technology, which controls the block making

A. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

B. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

C. Power saving: 30%; -

Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

A. Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

B. Guarantee production stability; -

360° Multi-Shaft Rotating and Compulsory Feeding:

A. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

B. This uniform feeding is applicable for different kinds of raw materials and moulds; -

Use heat treatment on moulds and main parts of the machines:

A. Heavy duty machine structure and wear resistant moulds;

B. The hardness reaches up to HRC 52-58;

C. Greatly improves the using lifetime of the machine by 50%. m: +8615092894665(whatsapp,wechat) skype: lyhebe -

|

Name

|

block size

|

block making period

|

blocks per mold

|

Production capacity

|

|

Hollow block

|

400x200x200

|

15-20s

|

6

|

1440-1080pcs/hour

|

|

Multi-hole brick

|

240x115x90

|

15-20s

|

18

|

4320-3240pcs/hour

|

|

Solid brick

|

240x115x53

|

15-20s

|

40

|

9600-7200pcs/hour

|

|

paver

|

200x100x60

|

20s

|

27

|

4860pcs/hour

|

|

Ishape paver

|

200x163x60

|

20s

|

18

|

3240pcs/hour

|

block moulding machine prices in nigeria Automatic Concrete Block Making Machine 6 Inches Features:

1)Control System:

Electric control system consists of imported color touch screen and programmed PLC with data input and output device, including safety logical control and trouble shooting system.Vibration analyzing system:detecting the vibration frequency, vibration amplitude,vibration acceleration and noise of the whole machine,so as to adjust the vibration to optimum efficiency.

2)Hydraulic System:

The system consists of imported components and seals with high dynamic performance proportional valves. The action of key cylinders can be operated through the regulator of flow and pressure according to the working requirement.The main frame is wide for the convenience of mold filling, so more blocks can be made. In order to get even pressure, three oil reservoirs are used, which raise the pressure to as high as 100t. Moreover, the smallest reservoir in the middle increases the operating speed of the left and right ones respectively, thus improving the productivity

.

3) Frequency conversion motor drive the vibrating case,easy to obtain ideal vibration force,vibration frequency and amplitude,can produce high quality block. Unique double-vibration box drives all in one vibration table to make the deviation of amplitude lower,more even so as to guarantee the consistency firm and durable.

4) Adopts more advanced material-feeding technology,material from the hopper fall into the mould case rapidly and evenly,make the weight error less than ±5%,the intensity error less than≤±15%.

5) Compared with common Block Making Machine,these equipment investment has increased by about 18%,but output has been improved by 35%,unit consumption has been reduced by about 5%.

6)

incomparable advantages in producing process:

High thickness and rectangle steel frame, four guidance column, solidity structure and prolonged life.

spare parts of block machine used for Concrete Brick Raw Material

block moulding machine prices in nigeria Automatic Concrete Block Making Machine 6 Inches

This is the most popular proportion in making block making machine:

1. S tandard concrete block : Cement 9-12% , sand 40% , stone 45%, water 3%

2. L ight concrete block : Cement 9-12% , slag 80-90%, water 3%

3. Cement 9-12% , sand 10-20% , stone 30-40% , slag 25-50%, water 3%

4. C ement 8%-10%, sand 30%-40%, stone 50%-60%

5. C ement 8%, sand 60%, Fly ash 30%, gypsum 2%.

block moulding machine prices in nigeria Automatic Concrete Block Making Machine 6 Inches packing and shipping

block moulding machine prices in nigeria Automatic Concrete Block Making Machine 6 Inches

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, planThe condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime,if you need, we can Make inVitation card for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix,and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other

The reasons to choose Donyue

-

1. Dongyue group is the top 3 of block machine industry

, manufacturing for more than 26 years.

2. Advanced German technology and high performance for long time

3. We use GB Q235 steel which should be through carburizing heat treatment for the moulds, which will prolong the machine life span for at least 5 years.

4. Timely and effective after-sales service

1) If you'v got a brick factory and you want to improve your current formal and save the cost, our professional team are willing to give you the best suggestion and technical support.

2) If you want to join in this filed, our professional team would like to offer you the best guidance and give you a full appreciation about our machine and the the feasibility of its investment.

3) If you are doubt about your raw material or whether it could be formed as a perfect brick. Don't be worry about that. Just contact us. Send your local material to us by post. We can offer you the test for free. We firmly believe that any kinds of raw material could be a useful one with the help of our machine.

5. Our company have offices in Indonesia, Vietnam and India, our clients are across the whole world. 6. Donyue Machinery Group is the first one to get the famous trade mark of China - 7. The company was the first in the industry to get ISO9001:2000 certification and the CE marking

- 8. We have undertaken research and manufacture of national Torch Scheme, national key new product scheme etc. and got 30 in v ention patents, 25 new practical patents, and also awards of nat ional energy scientific progress, Shandong outstanding energy-saving award, Shandong scientific award etc.