- Product Details

- {{item.text}}

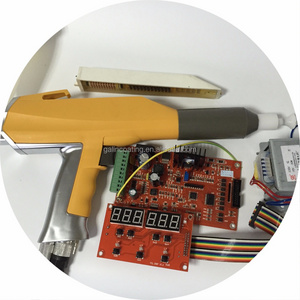

Quick Details

-

Power:

-

40w

-

Dimension(L*W*H):

-

45*45*65

-

Weight (KG):

-

35

-

Lab Gun:

-

Powder coatings Machines

-

Color:

-

yellow

Quick Details

-

Machine Type:

-

Spray Gun, Spray Booths, Painting Equipment, Coating Equipment

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

220v

-

Power:

-

40w

-

Dimension(L*W*H):

-

45*45*65

-

Weight (KG):

-

35

-

Lab Gun:

-

Powder coatings Machines

-

Color:

-

yellow

Product Overview

Lab Powder Coatings Machines

This Lab

Powder Coatings Machines are

profession designed for wheels Powder Coating curing,include:GEMA Spray Gun, Electric hot air Oven, and painting booth, which are basic on our 22 years powder coatings produce experience especial the forged wheels produce experience.

The Specialities are:

1.) "

Wheels are very thick

" especial the forging rims's hub holes part's thickness are very thick; So, it need the oven very

high efficiency heating

; So, 4 rims oven,we designed 24KW; and 8 rims 30KW.

2.)

Energy saving

is quite important, so, we designed 3 levels walls, to protect the heat release.

3.)

Balanced temperature

for rim's color balance is very important,so,we designed the heating system in 2# of the 3 walls. Also, equipped the fans on make the temperature balanced.

4.)All

Welding Technic

, simply and strong.

FEATURES AT A GLANCE

* High Efficient Heating

* 3 Walls Structure, Energy Saving

* High Efficiency Heating

* Balanced Temperature

* Rims Laying Down Curing, better for surface leveling

Right View

Front View

LEFT VIEW

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

||

|

1

|

Power Input

|

AC 380V ±10%,50Hz

|

|

|

||

|

2

|

Power

|

24KW or 30KW

|

|

|

||

|

3

|

Interior Dimension

|

L*W*H=1.5m*2.2m*1.8m

|

|

|

||

|

4

|

Outside Dimension

|

L*W*H=2.0m*2.4m*2.2m

|

|

|

||

|

5

|

Heating Preservation Board

|

12cm quartz cotton

|

|

|

||

|

6

|

Best Working Temperature Range

|

Max 250

o

C, best working range 160~220 oC.

|

|

|

||

PRODUCT CONFIGURATION

So Thick 3 layers Walls

Laser Cutting Mateial

Welding, for strong structure

SALES AND SERVICE NETWORK

Successful Project

Project in Dubai

Project in Germany

Project in Egypt

SIMILAR PRODUCTS

FAQ

Q1:How many days to delivery after payment

A1:Within 20 working days

Q2:Are the oven suite for 220V?

A1:Yes, and please inform us ahead when in ordering.

Q3:Can the dimension bigger or smaller ?

A3:Yes, we are welcome such of OEM Orders.

Q4: Stainless Steel?

A4:Can be, and

please inform us ahead when in ordering.

Hot Searches