- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000

-

Weight (KG):

-

1500 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

zhitong

-

Voltage:

-

380v 220v customized

-

Dimension(L*W*H):

-

150*150*300cm

-

Power (kW):

-

18.5 kW

-

Usage:

-

Cosmetic Industry

-

Name:

-

cosmetic industry homogenizer

-

Capacity:

-

300L

-

Heating method:

-

Steaming Heating/electric heating

-

Advantage:

-

Vacuum System

-

Surface finish:

-

Polishing < 0.4

-

Speed:

-

Frequency Conventer Control

-

MOQ:

-

1 Set

-

Dimension:

-

custom made

Quick Details

-

Barrel Volume (L):

-

5000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 63 r.p.m

-

Max. Loading Capacity:

-

5000

-

Weight (KG):

-

1500 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

zhitong

-

Voltage:

-

380v 220v customized

-

Dimension(L*W*H):

-

150*150*300cm

-

Power (kW):

-

18.5 kW

-

Usage:

-

Cosmetic Industry

-

Name:

-

cosmetic industry homogenizer

-

Capacity:

-

300L

-

Heating method:

-

Steaming Heating/electric heating

-

Advantage:

-

Vacuum System

-

Surface finish:

-

Polishing < 0.4

-

Speed:

-

Frequency Conventer Control

-

MOQ:

-

1 Set

-

Dimension:

-

custom made

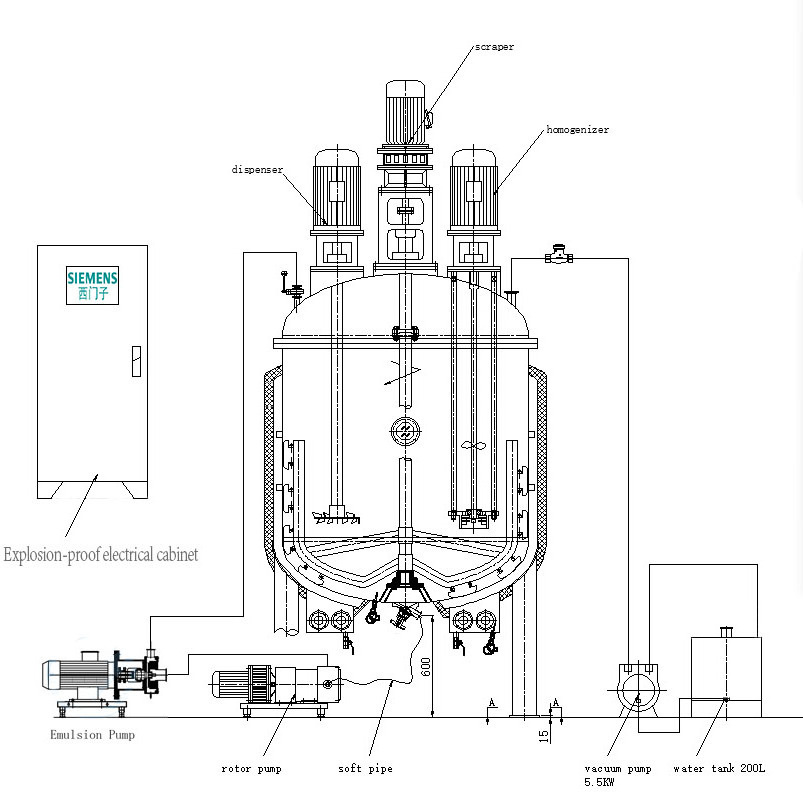

Products Description

Product Detail:

vacuum homogenizer machine, the most advanced homogenizer machine design from Germany and is especially suitable for drug

emulsion, ointment, snow cream, mask, face cream, emulsion essence, oil-water emulsion, emulsion asphalt, resin emulsion, wax

emulsion

1. Vacuum emulsifier main pot: Main pot hydraulic lifting .three layers of stainless steel structure (ss304 ss316), can be

manually tipped out. Equipped with material inlet, vacuum gauge, vacuum valve, view mirror, air filter, perfume hopper and so

on.

2. Lifting emulsifier series , including emulsifying pot , operating platform, oil and water pot , oil and water pot and

controller; Emulsifying pot device including emulsifying pot, emulsifying pot rack and emulsifying pot cover fixed plate,

emulsifying pot set on mixing mechanism, dumping, cooling circulation mechanism, vacuum institutions and emulsifying pot cover

lifting mechanism, mixing, dumping, cooling cycle machine, vacuum institutions and emulsifying pot cover the controlled end of

the lifting mechanism is connected to the output of the controller.

bottom homogenizer:adopted Simens motor Variable frequency speed 0-3000rpm , motor director drive method offer bigger torque

for material homogenizer process save power. stable operation and long service life, unique flat bottom valve for three tanks

for residential material freely can be also manually the main pot discharging and auto discharging product

3. Variable mixing speed : 0-63RPM. clockwise and anti-clockwise direction mixing variable frequency speed regulation,

4.Modular design for easy installation and transfer and maintenance equipment

5.The support adjustment wheel design is easy to adjust the level. Extend the service life of equipment

6.PLC controller make easy to operate machine

7.The key parts of the original imported famously brand suppliers to ensure the quality of worry-free

8.The GMP standard fast fittings and pipe. Eary to install machine and clean system

9. uniquely paddle design making easy to clean process

zhitong vacuum emulsifier advantages:

1, variety, homogeneity on homogeneity, homogeneity, internal and external circulation homogeneity, mixing with double, one-way,

screw belt stirring, lifting points hydraulic and double cylinder lifting, choose more gameplay.

2. German homogenizing technology, emulsifying speed up to 4200 RPM

3.PLC control, make production more intelligent;

4. Convenient cleaning, convenient and economical;

5, covers an area of small, and do not lose the modern beauty;

vacuum homogenizer machine, the most advanced homogenizer machine design from Germany and is especially suitable for drug

emulsion, ointment, snow cream, mask, face cream, emulsion essence, oil-water emulsion, emulsion asphalt, resin emulsion, wax

emulsion

1. Vacuum emulsifier main pot: Main pot hydraulic lifting .three layers of stainless steel structure (ss304 ss316), can be

manually tipped out. Equipped with material inlet, vacuum gauge, vacuum valve, view mirror, air filter, perfume hopper and so

on.

2. Lifting emulsifier series , including emulsifying pot , operating platform, oil and water pot , oil and water pot and

controller; Emulsifying pot device including emulsifying pot, emulsifying pot rack and emulsifying pot cover fixed plate,

emulsifying pot set on mixing mechanism, dumping, cooling circulation mechanism, vacuum institutions and emulsifying pot cover

lifting mechanism, mixing, dumping, cooling cycle machine, vacuum institutions and emulsifying pot cover the controlled end of

the lifting mechanism is connected to the output of the controller.

bottom homogenizer:adopted Simens motor Variable frequency speed 0-3000rpm , motor director drive method offer bigger torque

for material homogenizer process save power. stable operation and long service life, unique flat bottom valve for three tanks

for residential material freely can be also manually the main pot discharging and auto discharging product

3. Variable mixing speed : 0-63RPM. clockwise and anti-clockwise direction mixing variable frequency speed regulation,

4.Modular design for easy installation and transfer and maintenance equipment

5.The support adjustment wheel design is easy to adjust the level. Extend the service life of equipment

6.PLC controller make easy to operate machine

7.The key parts of the original imported famously brand suppliers to ensure the quality of worry-free

8.The GMP standard fast fittings and pipe. Eary to install machine and clean system

9. uniquely paddle design making easy to clean process

zhitong vacuum emulsifier advantages:

1, variety, homogeneity on homogeneity, homogeneity, internal and external circulation homogeneity, mixing with double, one-way,

screw belt stirring, lifting points hydraulic and double cylinder lifting, choose more gameplay.

2. German homogenizing technology, emulsifying speed up to 4200 RPM

3.PLC control, make production more intelligent;

4. Convenient cleaning, convenient and economical;

5, covers an area of small, and do not lose the modern beauty;

Large size Vacuum Emulsifying Mixer

Small size Vacuum Emulsifying Mixer

|

Profile

|

Single layer tank

|

Double layer tank

|

Three layer tank

|

||

|

Tank material

|

SS304 or SS316L

|

|

|

||

|

Volume

|

up to 20T

|

|

|

||

|

Pressure

|

Vacuum-1Mpa

|

|

|

||

|

Structure

|

one layer

|

Inner layer+jacket

|

inner layer+jacket+insulation

|

||

|

Cooling method

|

No

|

ice water /cooling water

|

ice water /cooling water

|

||

|

heating method

|

NO

|

electric/steam heating

|

electric/steam heating

|

||

|

|

per customer requirement

|

|

|

||

|

|

speed 0--63 rpm

|

|

|

||

|

PARTS DETAILS

|

open manhole / Pressure manhole

|

|

|

||

|

|

Various types of CIP cleaners

|

|

|

||

|

|

Sterile respirator

|

|

|

||

|

|

Inlet and Outlet sanitary valve

|

|

|

||

|

|

Inlet and Outlet sanitary valve

|

|

|

||

|

|

7.Paddle blender .(According to customer requirements)

|

|

|

||

|

|

9.Ladder

|

|

|

||

Technical parameter

|

Model

|

capacity

|

Homogenizer motor

|

|

Agitator motor

|

|

Size MM

(D*H*H) |

Limit vacuum (mpa)

|

||

|

|

|

kw

|

RPM

|

kw

|

RPM

|

|

|

||

|

1000

|

1000L

|

5.5

|

0--3000

|

5

|

0-63

|

Φ1000x1200*2200

|

-0.09

|

||

|

2000

|

2000L

|

7.5

|

0--3000

|

5

|

0-63

|

Φ1200x1500*2500

|

-0.09

|

||

|

3000

|

3000L

|

9

|

0--3000

|

7

|

0-63

|

Φ1600x1500*2750

|

-0.09

|

||

|

4000

|

4000L

|

11

|

0--3000

|

7

|

0-63

|

Φ1600x1850*2950

|

-0.09

|

||

|

5000

|

5000L

|

14

|

0--3000

|

11

|

0-63

|

Φ1800x2000*3300

|

-0.09

|

||

|

6000

|

6000L

|

14

|

0--3000

|

11

|

0-63

|

Φ1800x2400*3750

|

-0.09

|

||

|

7000

|

7000L

|

18.5

|

0--3000

|

11

|

0-63

|

Φ4200*4800*5400

|

-0.09

|

||

|

Up to 20000

|

|

|

|

|

|

|

|

||

Machine details

Machine application

Making cosmetic cream, skin cream, eye cream, hair conditioner, hair dye

cream, ointment, emulsification and ointment and so on

Hot Searches