- Product Details

- {{item.text}}

Quick Details

-

Max.Transformer Capacity(kVA):

-

15 kVA

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Greens copper wire coil winding machine

-

Motor Power (kw):

-

18

-

Weight (KG):

-

2000

-

Wire Diameter Range (mm):

-

2.2 - 6 mm

-

machine function:

-

draw any kind of wire

-

wire:

-

copper,aluminum, iron, steel

-

drawing mold:

-

offer all kinds

-

max input wire diameter:

-

12.7mm

-

wire material:

-

Q235, Q195

-

frequency control:

-

have

-

max speed:

-

25M/S

-

Gurantee period:

-

1 year

-

mini output wire diameter:

-

0.5mm

-

Product name:

-

copper wire coil winding machine

Quick Details

-

Max. Load (KG):

-

2800 KG

-

Length of Axis (mm):

-

560 mm

-

Center Height (mm):

-

1000 mm

-

Max.Transformer Capacity(kVA):

-

15 kVA

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Greens copper wire coil winding machine

-

Motor Power (kw):

-

18

-

Weight (KG):

-

2000

-

Wire Diameter Range (mm):

-

2.2 - 6 mm

-

machine function:

-

draw any kind of wire

-

wire:

-

copper,aluminum, iron, steel

-

drawing mold:

-

offer all kinds

-

max input wire diameter:

-

12.7mm

-

wire material:

-

Q235, Q195

-

frequency control:

-

have

-

max speed:

-

25M/S

-

Gurantee period:

-

1 year

-

mini output wire diameter:

-

0.5mm

-

Product name:

-

copper wire coil winding machine

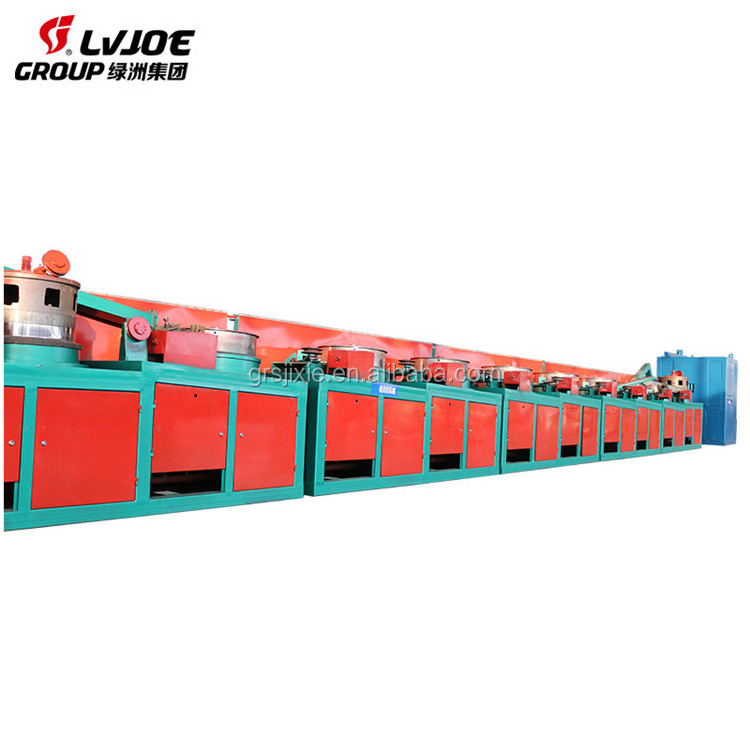

copper wire coil winding machine

We are manufacturer from Shijiazhuang of Hebei province near to Beijing .

Introduction of copper wire coil winding machine

This machine can be used to draw wires of low, medium and high carbon steel, copper and aluminum . It is suitable for manufacturing industries of nail wire, electric lead, copper ropes, spring etc. Adopting electrical control, it is more easy to operate with low noi-se and high efficiency.

Advantages of copper wire coil winding machine

-Work efficiency is very high, the running speed is higher than other kinds of wire drawing achines

-It is very easy to operate

-with an intelligible man-computer interface

-The quality of finished steel wire is the best if use the straight line wire drawing machine

- Environmental protection because of installing protective cover on machines

-With high performance cooling system for cooling,water cooling and high pressure wind cooling

-Working life of capstan is more than 22000 hours

Specification of copper wire coil winding machine

|

Times of drawing |

Drum dia |

Max inlet dia |

Min outlet dia |

Speed |

Single power |

Input strength |

|

|

2-11 |

300mm |

2.8mm |

0.5mm |

25m/s |

7.5-18.5KW |

≤1250MPA |

|

|

2-11 |

350mm |

3.5mm |

0.6mm |

20m/s |

11-22KW |

||

|

2-11 |

400mm |

4.2mm |

0.75mm |

20m/s |

11-30KW |

||

|

2-12 |

450mm |

5mm |

1mm |

16m/s |

15-37KW |

||

|

2-12 |

500mm |

5.5mm |

1.2mm |

15m/s |

22-45KW |

||

|

2-12 |

560mm |

6.5mm |

1.4mm |

15m/s |

22-55KW |

||

|

2-12 |

600mm |

8mm |

1.6mm |

12m/s |

30-75KW |

||

|

2-9 |

700mm |

10mm |

2.2mm |

12m/s |

45-90KW |

||

|

2-9 |

800mm |

12.7mm |

2.6mm |

8m/s |

55-110KW |

||