- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JND

-

Dimension(L*W*H):

-

3000x1800x1200

-

Power (kW):

-

11 kW

-

Product name:

-

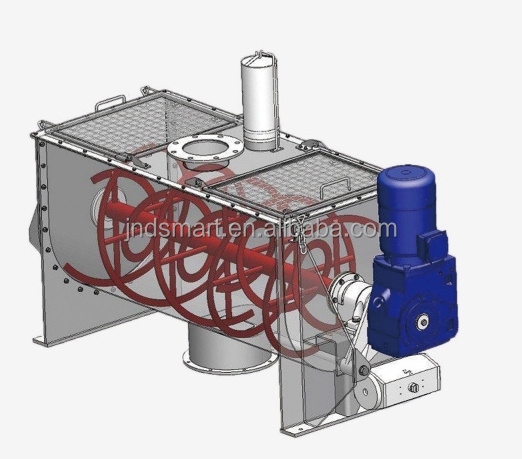

1000L Horizontal Ribbon Blender

-

Mixed Material:

-

Powder

-

U-Shaped Cylinder:

-

SUS304,SUS316L

-

Drives:

-

A.motors, reducers, etc

-

Shaft End Seals:

-

Packing Seal + Labyrinth Seal + Gas Seal

-

Mixing Device:

-

Main Shaft, Ribbon Branches and Propeller Blades

-

Propeller Blades:

-

Double Layers

-

Mixing Device Material:

-

SUS304,SUS316L

-

Mixing type:

-

Ribbon

-

Application scope:

-

Powder Mixing

Quick Details

-

Barrel Volume (L):

-

1000L

-

Max. Loading Volume (L):

-

600 L

-

Weight (KG):

-

1800 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JND

-

Dimension(L*W*H):

-

3000x1800x1200

-

Power (kW):

-

11 kW

-

Product name:

-

1000L Horizontal Ribbon Blender

-

Mixed Material:

-

Powder

-

U-Shaped Cylinder:

-

SUS304,SUS316L

-

Drives:

-

A.motors, reducers, etc

-

Shaft End Seals:

-

Packing Seal + Labyrinth Seal + Gas Seal

-

Mixing Device:

-

Main Shaft, Ribbon Branches and Propeller Blades

-

Propeller Blades:

-

Double Layers

-

Mixing Device Material:

-

SUS304,SUS316L

-

Mixing type:

-

Ribbon

-

Application scope:

-

Powder Mixing

APPLICATION RANGE

This product is widely used in battery materials, compound fertilizer, chemicals, ceramic refractory materials, putty paste, real stone paint, biological, pharmaceutical, food, mortar and other fields. It can be used for the mixing of powder and powder, can also be used for the mixing of powder and liquid, and can also be mixed with paste, thick or heavy materials (such as putty, real stone paint, metal powder and other products).

| Model | Volume(L) |

Working Volume(L) |

Power(KW) |

| MPS-1000 | 1000 | 300-600 | 11 |

| MPS- 3 000 | 3000 | 900-1800 | 18 |

| MPS- 5 000 | 5000 | 1500-3000 | 30 |

| MPS-10 000 | 10000 | 3000-6000 | 55 |

| MPS-15 000 | 15000 | 4500-9000 | 90 |

| MPS-20 000 | 20000 | 6000-12000 | 110 |

| MPS-30 000 | 30 000 | 9000-18000 | 132 |

| MPS-40000 | 40000 | 12000-24000 | 160 |

Remarks:

The above specification parameters are measured when the material density is less than 1g/cm3 powder as the medium, the selection should be calculated according to the material mesh, density and other parameters;

You can propose the processing volume, equipment form, size requirements or the material characteristics and process you need to process, Jianengde sales engineers will provide you with a satisfactory solution.

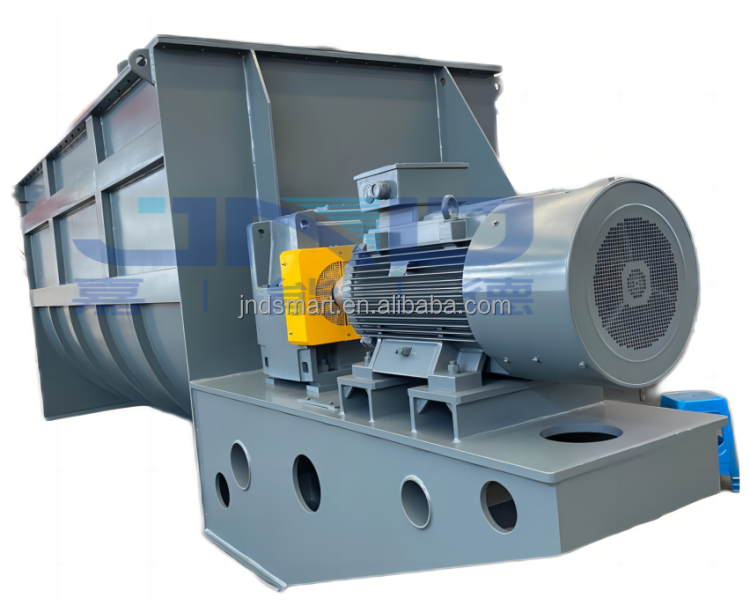

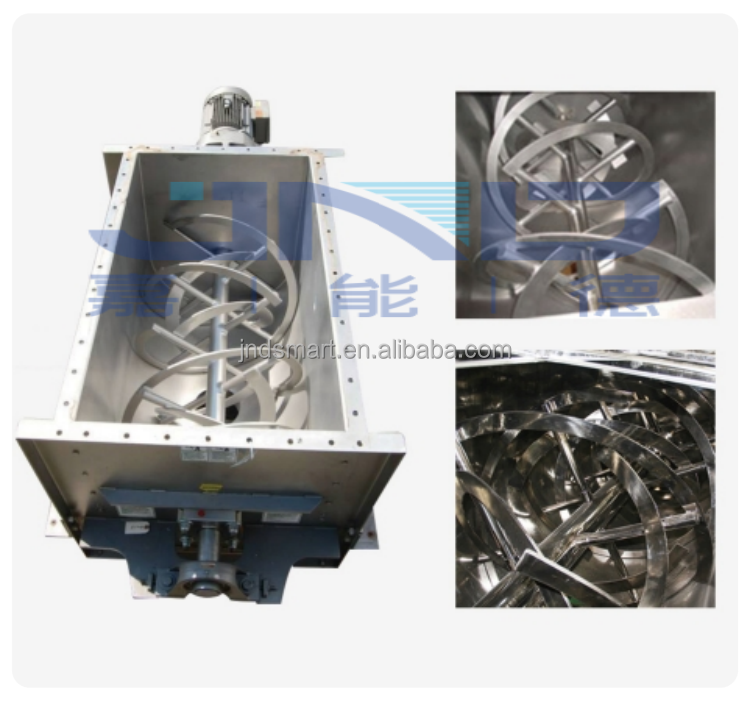

PRODUCT DISPLAY

Product Picture

Show Details

A. Drives - motors, reducers, couplings, bearings, etc

1) Motor Selection: SEW Motor, Siemens Motor, Wolong Motor, JIAMUSI motor, WanNan Motor, Nanjing DYT Motor, etc.

2)Reducer (Gearbox) Selection: SEW, Flender, TaiLong, GuoMao, Tongli, etc

B:Shaft End Seals - Packing Seal + Labyrinth Seal + Gas Seal

Shaft Seal: Packing seal + Labyrinth seal + gas seal, or other types.

C:Mixing Device - Main Shaft, R ibbon Branches and Propeller Blades,etc

Main Shaft, Ribbon Branches and Propeller Blades : SUS304, SUS316L, or others.

D: U- S haped Cylinder - B arrel B ody, B arrel C over, W all board and R einforced P lates and S teel

Barrel cover, Barrel body, Barrel Wallboard: SUS304, SUS316L, or others.

E:C ylinder I nterface ( T entatively, S ize and P osition of N ozzle shall be subject to orientation diagram of the nozzle provided by the customer )

It comprises feeding port, breathing port, dust removal port, discharge port, spare port, etc

F : Surface treatment (if required) - targeted addition of anti-corrosion, wear and other functional coatings or protective layers

1 ) PTFE liner - the inner surface of the barrel body, the barrel cover and the wall board,which in contact with the material is lined with PTFE;

2) Tungsten carbide/nano-ceramic spraying - mixing device ( main shaft , ribbon branches and propeller blades ) , which in contact with the material, spraying tungsten carbide, or spraying nano-ceramics;

3) Stainless steel surface - blast sanding;

4) Carbon steel outer surface - paint treatment, using lithium battery special water-based paint (forbidden copper zinc).

F: Optional: control system, weighing system, dust removal system, sampler, etc

1) Weighing system includes weighing modules, weighing instrument and junction box, etc.;

2) The dust removal system includes a breathing valve, with a blowback function;

3) The control system includes electric control cabinet, gas control box, frequency converter, touch screen, PLC, low-voltage electrical components, cables, etc.

Logistics Instructions

The main body of the equipment and other supporting equipment (such as weighing system, dust removal system, control system, etc.) when the horizontal ribbon mixer is shipped. If the main body of the equipment can be placed in the container, it will be placed in the container for sea transportation; If the width or height exceeds the container, the simple plastic film (or bare) is placed on the channel steel frame, fixed with wire rope, and then covered with waterproof cloth and net rope. Other supporting equipment is packed in fumigated or plywood wooden cases, and then wrapped in waterproof cloth.

Delivery Photos

1. About the price

The price in the information is the approximate wholesale price of our company, please contact us for the specific price.

2. About delivery

We will arrange production and delivery according to the time determined by the contract, and we have special persons to strictly check the quality of the goods, please rest assured that you can buy..

3. About delivery

We have Ex-Factory price, FOB price, CIF price, DDU, DDP and other delivery methods, before the formal cooperation of a variety of delivery methods for you to choose.

4. About after-sales

We have a professional team of engineers to guide the installation. Party A and Party B may negotiate the installation service based on the quantity of the project.

5. About the warranty

The warranty period of this product is 12 months after acceptance, or 18 months after delivery, whichever comes first.