- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

customized

-

Weight:

-

depends on final order

-

Application area:

-

alluvial gold ore

-

Capacity:

-

can provide any capacity as per customer's request

-

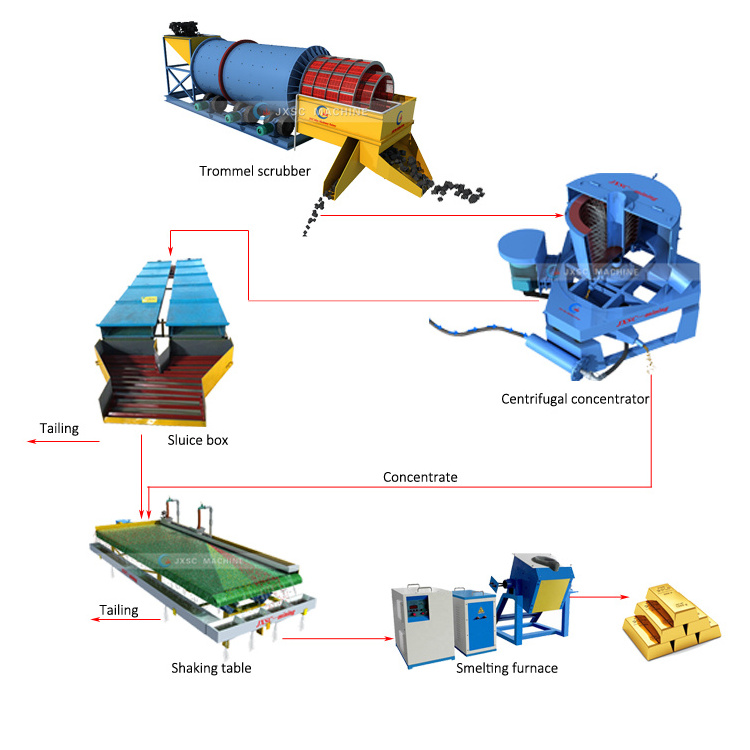

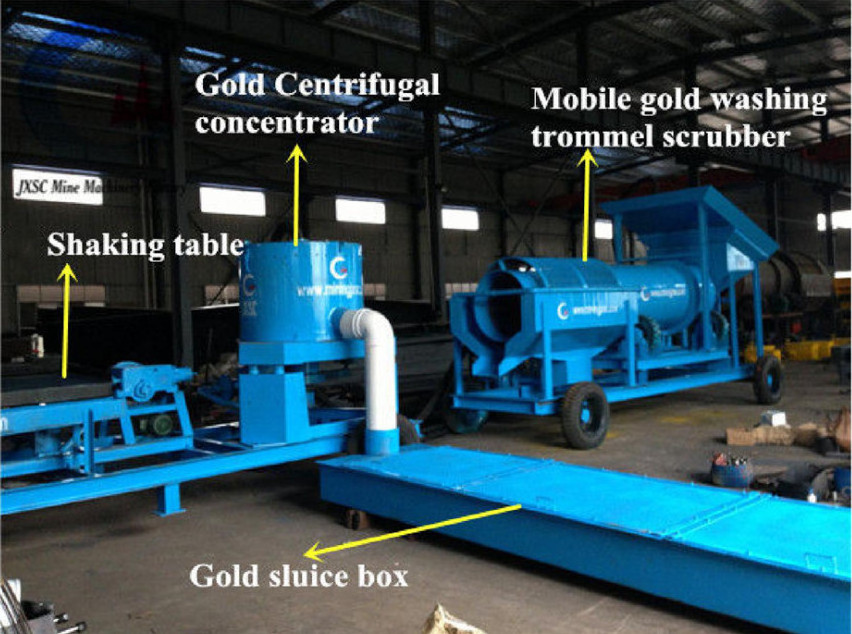

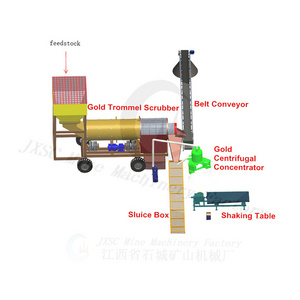

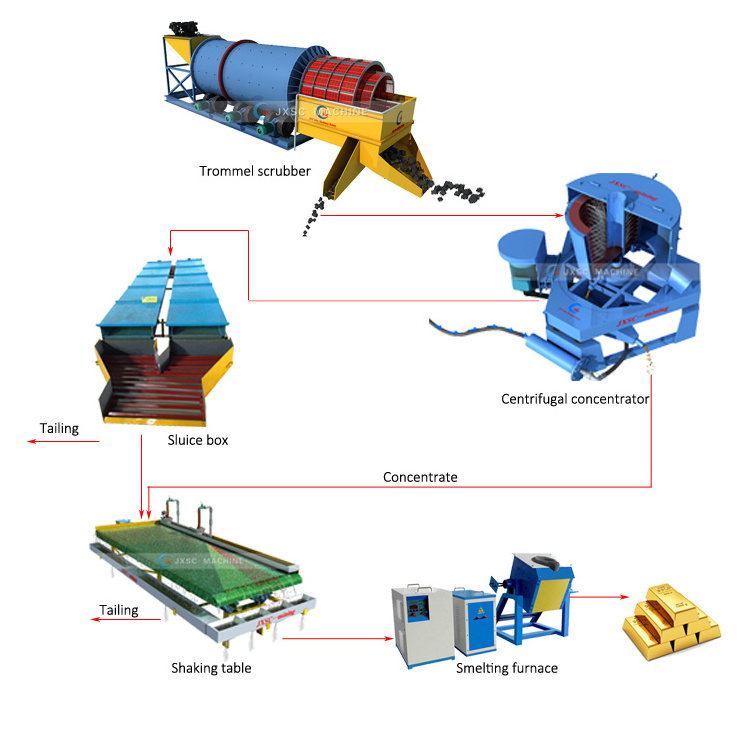

Main machines:

-

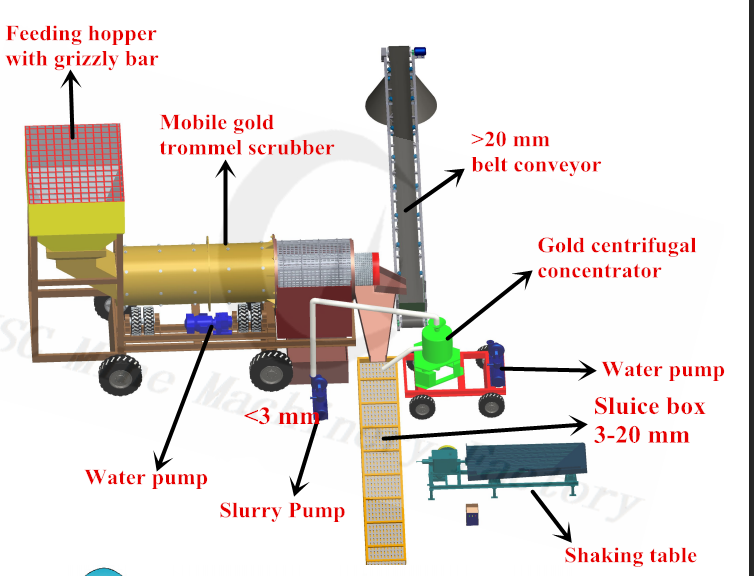

trommel washing machine, gravity separation machine

-

Auxiliary machines:

-

feeder,pumps,belt conveyor,hopper,steel plates etc

-

Technique:

-

Gravity separation technique,no any chemical process

-

Gold recovery ratio:

-

80% to 85%

-

Installation:

-

Provide plant layout drawing and engineer

-

Maintenance cost:

-

Lower

-

Features:

-

High efficiency,low investment cost,quick payback

-

After sale service:

-

Life long service

-

Certification:

-

BV, CE, SGS

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC or customerized

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

customized

-

Weight:

-

depends on final order

-

Application area:

-

alluvial gold ore

-

Capacity:

-

can provide any capacity as per customer's request

-

Main machines:

-

trommel washing machine, gravity separation machine

-

Auxiliary machines:

-

feeder,pumps,belt conveyor,hopper,steel plates etc

-

Technique:

-

Gravity separation technique,no any chemical process

-

Gold recovery ratio:

-

80% to 85%

-

Installation:

-

Provide plant layout drawing and engineer

-

Maintenance cost:

-

Lower

-

Features:

-

High efficiency,low investment cost,quick payback

-

After sale service:

-

Life long service

-

Certification:

-

BV, CE, SGS

Introduction of Trommel Scrubber Washer

Trommel Scrubber is a main washing equipment in mining industrial, widely used for washing alluvial type/sand type ores and stones, which with much sticky clay, with much good washing effect for clay.

This machine with two parts: drum scrubber and screen. The drum scrubber is for washing ore, screen is for sieving different size particles after washing.

Screen Material of Trommel Scrubber

1. Manganese steel: normal material, not easy to replace, 2-3 monthes life time.

2. PU material: wear-resistance, long life time 4-6 monthes, corrosion resistant, splicing technology, replacable, very easy to replace.

3. Stainless steel material : wear-resistance, long life time 4-6 monthes, corrosion resistant, splicing technology, not easy to replace.

Linning Plate Material of Trommel Scrubber

In order to increase the washing effect, we always put linning plates insider of the drum scrubber part, it can be made below two kinds material:

1. Iron material spiral plates: normal material, can't be replaceable, welded inside drum.

2. Natual Rubber lined plates: wear-resistance, long life time, corrosion resistant, fixed with screw, replacable, easy to replace.

Main structure of Trommel Scrubber Washer

1. Drum scrubber : For washing the clay.

2. Trommel scrubber Inner plate: separating the clay and ores, washing more clean the clay.

3. Trommel scrubber Sieving screen: for sieving different sizes ores, the screen mesh size& layer quantity & screen materials can be made according to customer need.

4. Motor: electric or diesel according to your needs.

5. Carrier rollers: For support the drum

6. Gear, Reduction Box, coupling.

7. Machine Frame: Supporting the reduction box and motor.

Specifications&Parameters of Trommel Scrubber

Hot Sale Firewood Trommel Screen Mobile Gold Wash Plant with Gold Centrifuge for Alluvial Gold Mining Machine

|

Model

|

Screen Size (MM)

|

Rotation Speed (R/Min)

|

Feeding size (mm)

|

Angle of inclination (degree)

|

Capacity (T/H)

|

Power (KW)

|

|

JXSC-400

|

≤20

|

27.9

|

≤80

|

≤10

|

1-5

|

3

|

|

JXSC-600

|

≤25

|

27.6

|

≤80

|

≤10

|

5-10

|

5

|

|

JXSC-750

|

≤25

|

27.6

|

≤100

|

≤10

|

10-30

|

7.5

|

|

JXSC-900

|

≤25

|

27.6

|

≤100

|

≤10

|

30-50

|

11

|

|

JXSC-1200

|

≤25

|

17

|

≤160

|

≤10

|

50-70

|

15

|

|

JXSC-1500

|

≤50

|

16

|

≤230

|

≤10

|

70-100

|

30

|

|

JXSC-1800

|

≤50

|

16

|

≤230

|

≤10

|

100-150

|

37

|

|

JXSC-2100

|

≤50

|

16

|

≤230

|

≤10

|

150-180

|

45

|

A: Yes, we are mining machinery manufacturer, our factory is located in Ganzhou City Jiangxi province, it has direct flight to Beijing,Shanghai,Guangzhou,Shenzhen Airport. Welcome to visit our factory!

Q:Can you produce as specific size?

A: Yes, most of our products are customized as per customer's requirements.

Q: What is the leading time?

A: For shaking table and laboratory mining equipment ,we can send out within 7 days after receiving full payment.

For large scale mining equipment and customized machine, the lead time is about 30-35 days.

Q: Do you supply oversea service?

A: Yes, we do. Engineers available to service machinery overseas.

Q: How about the warranty?

A: We will supply you one year warranty and lifelong technical support.