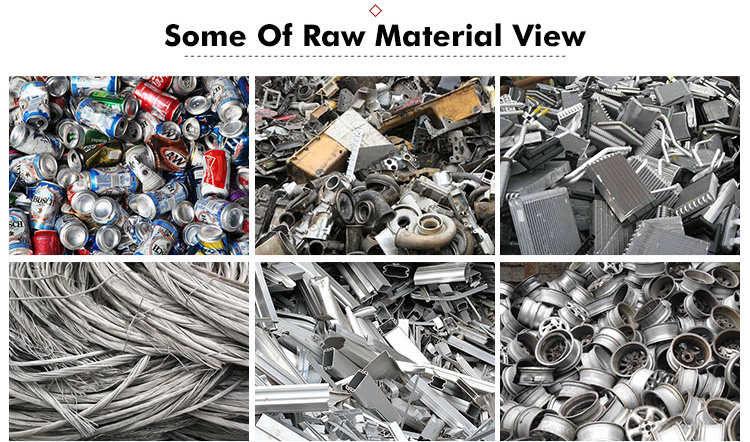

4. Eg:About aluminium cans,from scraps to final ingots.recovery efficiency can be 92%

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Not standard

-

Weight (T):

-

0.5 T

-

Power (kW):

-

160

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

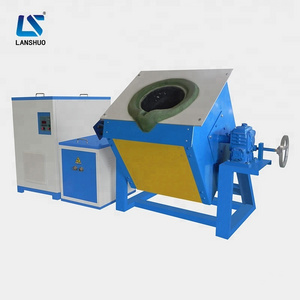

0.5 ton aluminum melting furnace

-

Other name:

-

metal steel,iron,copper,aluminum scrap melting

-

advantages:

-

save electricity

-

Weight:

-

300kg

-

Certification:

-

ISO9001:2008 CE

-

Melting Material:

-

Scrap Steel Copper Stainless Steel

-

Furnace type:

-

Induction Melting Electric Furnace

-

Capacity:

-

100kg-15T

-

Feature:

-

Environmental-friendly Fast

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

Melting furnace

-

Brand Name:

-

Hongteng

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Not standard

-

Weight (T):

-

0.5 T

-

Power (kW):

-

160

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

0.5 ton aluminum melting furnace

-

Other name:

-

metal steel,iron,copper,aluminum scrap melting

-

advantages:

-

save electricity

-

Weight:

-

300kg

-

Certification:

-

ISO9001:2008 CE

-

Melting Material:

-

Scrap Steel Copper Stainless Steel

-

Furnace type:

-

Induction Melting Electric Furnace

-

Capacity:

-

100kg-15T

-

Feature:

-

Environmental-friendly Fast

We are factory(

more than 15years experiences

) located in Luoyang, Henan provice, China.

We are a professional manufacturer of

Industrial electric furnace, Ingot casting line, Hot rolling mill and CCM

.

We can provide a total solution according to your request.

We can provide CE Certificate , Overseas installation and After-sales service.

You are welcome to send us enquiry or to visit our factory.

We can provide a total solution according to your request.

We can provide CE Certificate , Overseas installation and After-sales service.

You are welcome to send us enquiry or to visit our factory.

Product Description

1.Electric melting aluminum furnace.

2.Aluminium melting furnace use crucible to melt all kinds of waste aluminium.

2.Just connect to the electric, no need debugging,no need installation furnace will start to work

4.Air cooling type melting aluminium furnace

4.Air cooling type melting aluminium furnace

Not-tilting aliuminum furnace

T

ilting aliuminum furnace

Technologicalt Process

1. Can melt all kinds of aluminum cans ,aluminum powder,aluminium wires,aluminium ingots,aluminum wheels,aluminum alloy door window etc

2. From aluminum scraps to final ingots,including the treatment of aluminum ash after melting. the recovery efficiency will be around 92%.

Product Feature

1.Our Aluminum melting furnace is air cooling type,no need extra water cooling machine investment.easy to use.

2.We can supply all this line from scraps aluminum cans to final ingots.and we can also supply this line technology to our customers.

2.We can supply all this line from scraps aluminum cans to final ingots.and we can also supply this line technology to our customers.

1. Using high quality silicon crucible,Uniform and stable heating temperature,

2.The average life of crucible can be extended by more than 50%.

3. Equipment with a capacity below 3T can be cooled by air cooling without water cooling equipment;

1. Melt aluminum can be automatic pouring

2. The main control board is microcomputer control,

2. Aluminum liquid has no flow, no tumbling, reduces oxidation, and the composition remains unchanged during the smelting process.

1.This type aluminium melt furnace can be double chamber type

2. one chamber for filling in aluminium scraps.another chamber for melting

3. Furnace just connect to electric can use ,no need installation and debugging

4. we can teach our customer this technology to improve the aluminium recovery rate.

2. one chamber for filling in aluminium scraps.another chamber for melting

3. Furnace just connect to electric can use ,no need installation and debugging

4. we can teach our customer this technology to improve the aluminium recovery rate.

|

Specification and Technical Parameter

|

|

|

|

|||

|

Capacity

|

Powder

|

Voltage

|

Melting Time

|

|||

|

150kg

|

60KW

|

3*380V

|

60 Minutes

|

|||

|

300kg

|

120KW

|

3*380V

|

70 Minutes

|

|||

|

500kg

|

160KW

|

3*380V

|

80 Minutes

|

|||

|

1000kg

|

200KW

|

3*660V

|

90 Minutes

|

|||

Recommend Products

Why Choose Us

Certifications

Hot Searches