- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SINOGROUT

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1300*530*1220mm

-

Motor Power (Kw):

-

30KW

-

Power (kW):

-

30KW

-

Weight (KG):

-

900 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Wood Pellet Machine

-

Function:

-

Biomass Fuel Pellet Production Machine

-

Usage:

-

Making Wood Pellets Animal Feed Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Keywords:

-

Wood Pellet Machine Making

-

Type:

-

Flat Die Biomass Pellet Mill

-

After Warranty Service:

-

Ongoing Spare Parts Service

-

Certification:

-

CE ISO

-

Advantage:

-

High Producing Efficiency

-

Motor:

-

30KW

Quick Details

-

Pellet Diameter (mm):

-

2 - 12

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SINOGROUT

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1300*530*1220mm

-

Motor Power (Kw):

-

30KW

-

Power (kW):

-

30KW

-

Weight (KG):

-

900 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Wood Pellet Machine

-

Function:

-

Biomass Fuel Pellet Production Machine

-

Usage:

-

Making Wood Pellets Animal Feed Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Keywords:

-

Wood Pellet Machine Making

-

Type:

-

Flat Die Biomass Pellet Mill

-

After Warranty Service:

-

Ongoing Spare Parts Service

-

Certification:

-

CE ISO

-

Advantage:

-

High Producing Efficiency

-

Motor:

-

30KW

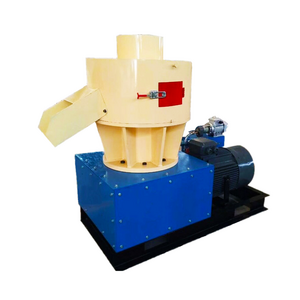

High industrial efficiency wood pellet making machine to make wood pellets machine biomass pellet machine for sale

Wood pellet machine is a biomass new energy source equipment and the granulation equipment of wood chips production. It is eucalyptus, birch, poplar, fruit trees, bamboo chips and crop straw as raw materials. Through the crushing, drying, screening, granulation, cooling, packaging and other processes to produce finished wood pellets. The final products can be used to biomass power generation, boilers, fireplaces, household appliances and so on.

Wood Pellet Machine Advantages:

1. Vertical feed, directly in place.

2. The mold is still, pressure roller rotation, material centrifugal, evenly around.

3. The mold has two layers, up and down dual-use, cost reduction efficiency; dual-use & high-yield

4. Annular mold, vertical structure, which facilitates the cooling of the granulation chamber.

5. Separate discharge device to ensure the formation rate of particles.

6. Independent automatic lubrication system brings a good bearing lubrication effect.

7. Feeding system has a frequency conversion device and achieves the adjustable of feeding speed. It can be applied to different materials.

Technical Parameter Of Wood Pellet Machine

Product Structure Diagram

Wide Range Of Raw Materials

Product Details

Product Details

Wood Pellet Production Line

Factory Display