- Product Details

- {{item.text}}

Quick Details

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

3kw

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

300 mm

-

Positioning Accuracy (mm):

-

0.02

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

1660*1280*1590mm

-

Brand Name:

-

SOSEN

-

Model Number:

-

Z0640

-

Voltage:

-

220V/380V/415V

-

Weight (KG):

-

1650

-

Marketing Type:

-

New Product

-

Name:

-

Z0640 High Precision CNC Flat Bed Horizontal Linear Guide Way Lathe

-

Max processing length:

-

300mm

-

Spindle bore:

-

48mm

-

CNC controller:

-

GSK SIEMENS FANUC

-

Spindle speed:

-

100-3000rpm

-

Spindle taper:

-

A2-5

-

Tool post:

-

gang type 4 pcs

-

Max.swing over carriage:

-

120mm

-

Max.size of tool post:

-

16*16mm

-

Chuck size:

-

5 inch chuck (optional)

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

300

-

Max. Spindle Speed (r.p.m):

-

3000 r.p.m

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

3kw

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

300 mm

-

Positioning Accuracy (mm):

-

0.02

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

1660*1280*1590mm

-

Brand Name:

-

SOSEN

-

Model Number:

-

Z0640

-

Voltage:

-

220V/380V/415V

-

Weight (KG):

-

1650

-

Marketing Type:

-

New Product

-

Name:

-

Z0640 High Precision CNC Flat Bed Horizontal Linear Guide Way Lathe

-

Max processing length:

-

300mm

-

Spindle bore:

-

48mm

-

CNC controller:

-

GSK SIEMENS FANUC

-

Spindle speed:

-

100-3000rpm

-

Spindle taper:

-

A2-5

-

Tool post:

-

gang type 4 pcs

-

Max.swing over carriage:

-

120mm

-

Max.size of tool post:

-

16*16mm

-

Chuck size:

-

5 inch chuck (optional)

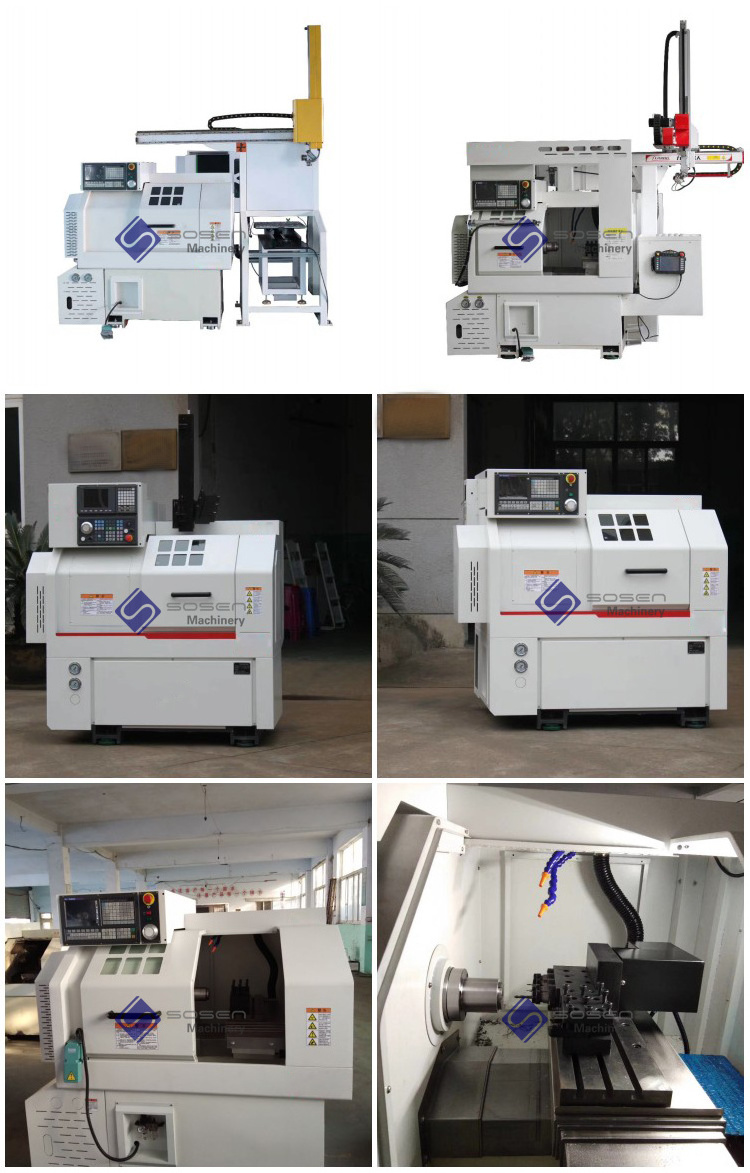

Z0640 High Precision CNC Flat Bed Horizontal Linear Guide Way Lathe

Feature:

1.1 The machine is reference to Switzerland and Japan advanced technology and design of new products, machine tools with high rigidity of the overall bed and concise full protection of the integration of the layout, the whole structure is compact, beautiful shape, stable and reliable performance, with Excellent precision retention.

1.2 machine can complete the straight line, arc, the British and metric thread, long thread processing, can be applied to the complex shape of the complex and high precision requirements of small-sized, short-axis parts processing.

1.3 Machine guide rails used linear guide way from Germany Rexroth , the machine has a higher speed and movement accuracy.

1.4 CNC system using Guangzhou CNC system GSK980TC3 and absolute value servo drive.

1.5 using Germany IF precision ball screw (X / Z two-way large screw Φ32mm) and domestic precision screw bearings, spindle bearings using HRB high-speed precision bearings .

1.6 high spindle speed, high precision, can achieve stepless speed and constant speed cutting, start and stop quickly.

1.7 The lubrication point of the use of forced automatic lubrication device for quantitative lubrication of the screw and guide rail, when the oil pressure or oil quantity is insufficient, the automatic warning signal will happen. To ensure that the lead screw and rail can be used in longer life and high precision

1.8 spindle nose A2-5 , to facilitate the installation of various fixtures connected.

1.9 machine with a fully enclosed protective device to prevent the coolant leakage, iron splash.

1.10 rail plus protection device to prevent the rails from being corroded by coolant liquid and iron chip, easy to clean iron chip.

1.11 electrical parts: relays, circuit breakers, contactors, all are form Schneider.

| Item | Unit | Z0640 | |

| Capacity | Max. swing dia. over bed | mm | Φ300 |

| Max. swing dia. over slide | mm | Φ120 | |

| Slide board size | mm | 550×190 | |

| Max. bar though dia. | mm | Φ40 | |

| Spindle | Spindle speed | rpm | 100~3000 |

| Spindle type | mm | A2-5 | |

| Spindle bore | mm | Φ48 | |

| Chuck size | / | 5'' (optional) | |

| Spindle bearing | pcs | Front 3+back 2 | |

| Spindle motor | kw | 3 (servo motor is option) | |

| Clamping device | / | Pneumatic collet,Hydraulic collet/chuck | |

| X/Z axes | X/Z axes travel | mm | 300/300 |

| X/Z axes servo motor | N.m | 4/4 | |

| X/Z axes rapid move speed | m/min. | 20/20 | |

| X/Z ball screw O.D./pitch | mm | Φ32/10 | |

| X/Z linear guideway width | mm | 25/25 | |

| X/Z repeatability accuracy | mm | ≤0.003/0.003 | |

| Tool post | Tool post | / | Gang tool 4 pcs |

| Toolshank size | mm | 16×16, Φ20 | |

| Coolant | Coolant pump | W | 180W (3 phase) |

| Tailstock | Tailstock | / | N/A |

| Work lamp | Work lamp | / | LED |

| Machining Accuracy | Finish turning dia. uniformity | mm | ±0.005 |

| Finish turning roundness | mm | ≤0.003 | |

| Finish turning flatness | mm | Φ300mm, Inner concave surface ≤0.025 | |

| Finish turning roughness | mm | Ra0.8~0.4 | |

| Machining Capacity | Steel Φ60 900rpm | / | F 0.1mm/r semidiameter cutting depth 2mm |

| Brass Φ100 800rpm | / | F 0.1mm/r semidiameter cutting depth 2mm | |

| Aluminium Φ100 800rpm | / | F 0.1mm/r semidiameter cutting depth 2mm | |

| Stainless steel Φ60 800rpm | / | F 0.1mm/r semidiameter cutting depth 1.5mm | |

| Others | Automatic lubrication pump | / | Quantitative type,20kgf/cm2, 10L , 220V |

| Overall size | mm | 1600×1200×1470 | |

| N.W. | kg | 1580 | |

Standard accessoires :

1) GSK980TC3 CNC controller

2) precision ball screw from Germany IF

3) linear guide way from Germany Rexroth

4) Lubrication system

5)Bearings from China top brand HRB

6) Work light LED

7) Gang type 4 pcs toolpost

8) pneumatic collet

9)X/Z-axis servo drive motor

10)full closed protection guard

10)spindle 3kw 3000rpm A2-5 bore 48mm