- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Spraying

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

yuanchuan

-

Dimension(L*W*H):

-

1260 740 630

-

Weight:

-

135 kg

-

Power:

-

2.2kw

-

Product name:

-

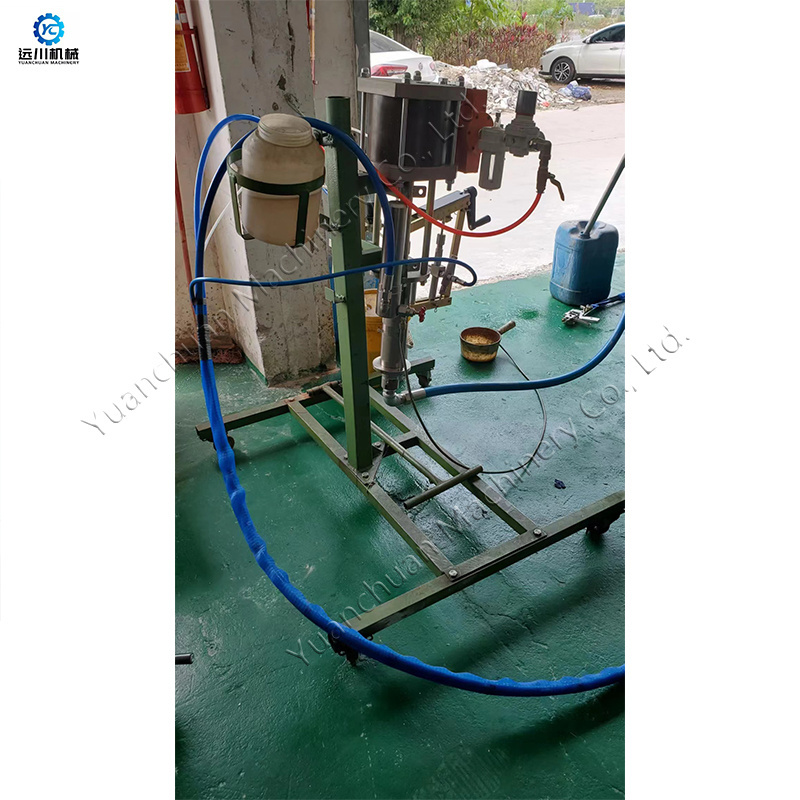

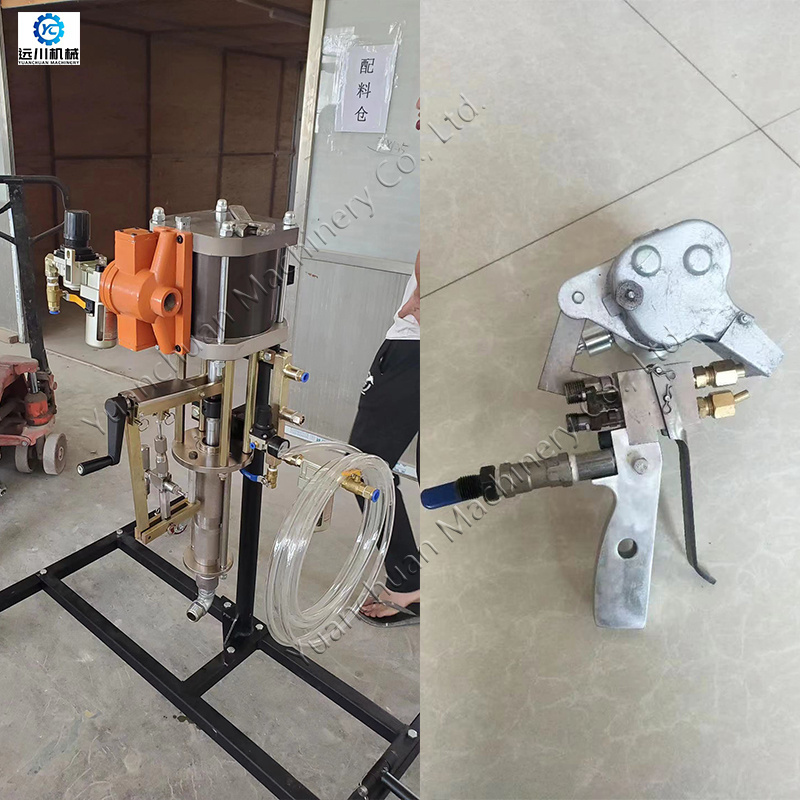

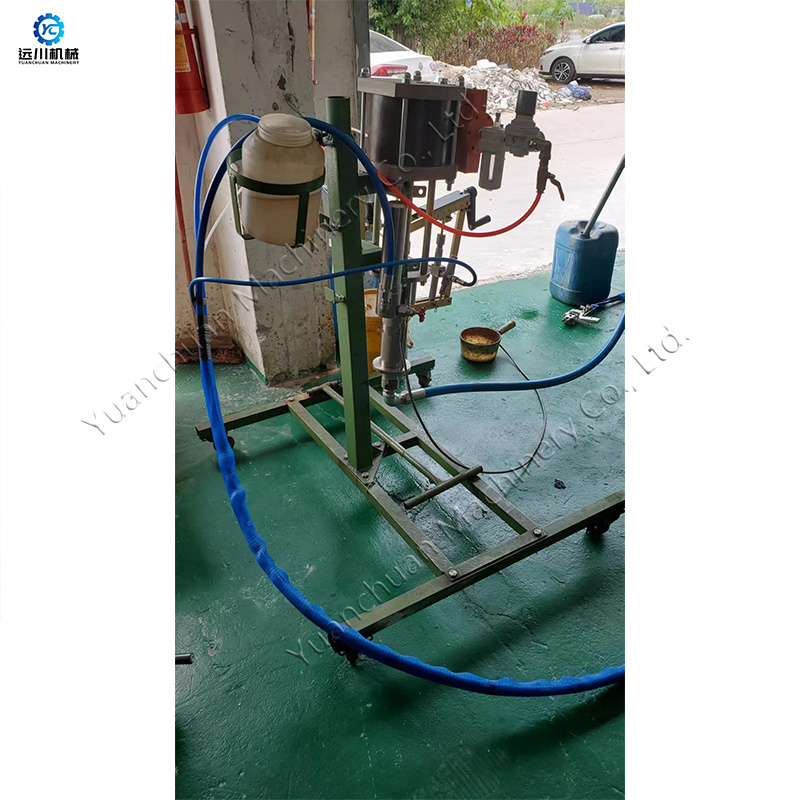

FRP spraying machine

-

COLOR:

-

optional

-

power:

-

air pump

-

Grouped equipment:

-

Blender

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Video technical support

-

kw:

-

3kw+2.2

-

Motor:

-

Infinitely adjustable speed motor

-

Blender description:

-

High speed mixer

Quick Details

-

Max. vertical conveying distance:

-

5M

-

Max. horizontal conveying distance:

-

5M

-

Hopper Capacity:

-

60L

-

Application:

-

Spraying

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

yuanchuan

-

Dimension(L*W*H):

-

1260 740 630

-

Weight:

-

135 kg

-

Power:

-

2.2kw

-

Product name:

-

FRP spraying machine

-

COLOR:

-

optional

-

power:

-

air pump

-

Grouped equipment:

-

Blender

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Video technical support

-

kw:

-

3kw+2.2

-

Motor:

-

Infinitely adjustable speed motor

-

Blender description:

-

High speed mixer

Product Description

Glass fiber reinforced plastic sprayer Glass fiber chopper Resin sprayer

Fiberglass Spray Equipment Machines are used to apply resins and fibers to workpieces

surfaced at the same time. Saving resin consumption is a modern technology

Labor costs compared to hand lay-up techniques widely used for FRP or GRP

Product mass production.

1. Precise proportional control. Catalyst driven pumps for precise catalyst ratios ensure parts cure at the desired rate.

2. Environmentally friendly. Airless spray reduces evaporation and contamination.

3. Cart and system. The whole system is installed on the chassis of the trolley, which makes the equipment movable and facilitates flexible spraying.

4. Flow management. Roving is guided by boom crutches, smoothing the roving, reducing tangles and increasing uptime.

5. Compact and light weight.

Packaging & Shipping

Hot Searches