- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V/220V/Optional

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

Ace-Filling

-

Dimension(L*W*H):

-

6100*2500*2200

-

Weight:

-

2700 KG

-

Warranty of core components:

-

Other

-

Keywords:

-

Drinking Water Filling Machine

-

Function:

-

Washing Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

3~10L

-

Capacity:

-

1000~12000BPH or other

-

Material:

-

Stainless Steel 304/316

-

Suitable for:

-

Water Filling Line

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Filling nozzles:

-

9/12/16/20 Pcs (customized)

-

Control:

-

PLC+ Touch Screen+Inverter

Quick Details

-

Machinery Capacity:

-

Other, 400BPH, 1000BPH, 200BPH, 600BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V/220V/Optional

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

Ace-Filling

-

Dimension(L*W*H):

-

6100*2500*2200

-

Weight:

-

2700 KG

-

Warranty of core components:

-

Other

-

Keywords:

-

Drinking Water Filling Machine

-

Function:

-

Washing Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

3~10L

-

Capacity:

-

1000~12000BPH or other

-

Material:

-

Stainless Steel 304/316

-

Suitable for:

-

Water Filling Line

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Filling nozzles:

-

9/12/16/20 Pcs (customized)

-

Control:

-

PLC+ Touch Screen+Inverter

Automatic mineral water 3L 5L 10L bottle wash filling capping machine for big bottle water producing equipment

|

Equipment Type | Automatic |

| Bottle Type |

PET round or square bottle

Volume:3-10L Bottle diameter 50-115mm |

|

| Output |

Rotary:1000 to 4500BPH

Linear:400 to 1500BPH |

|

| Your product | Mineral water/pure water/non-gas wine drink and so on. |

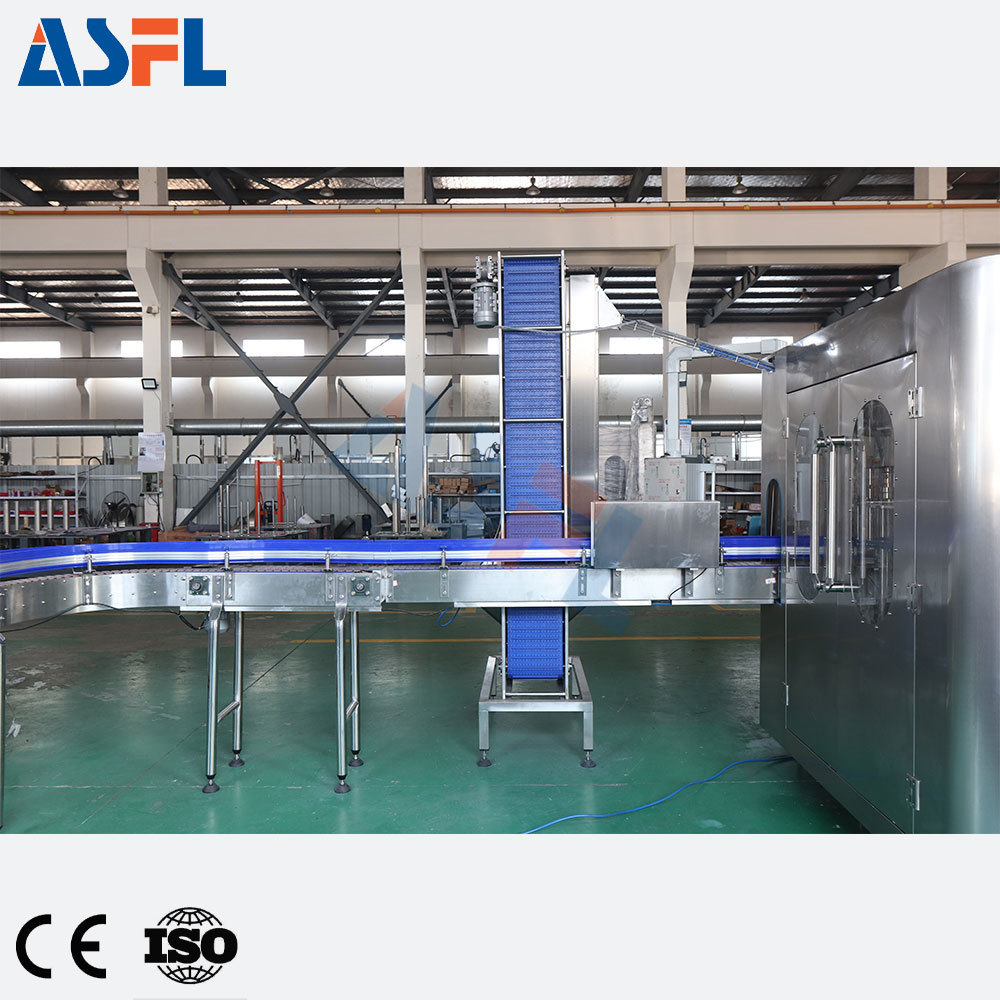

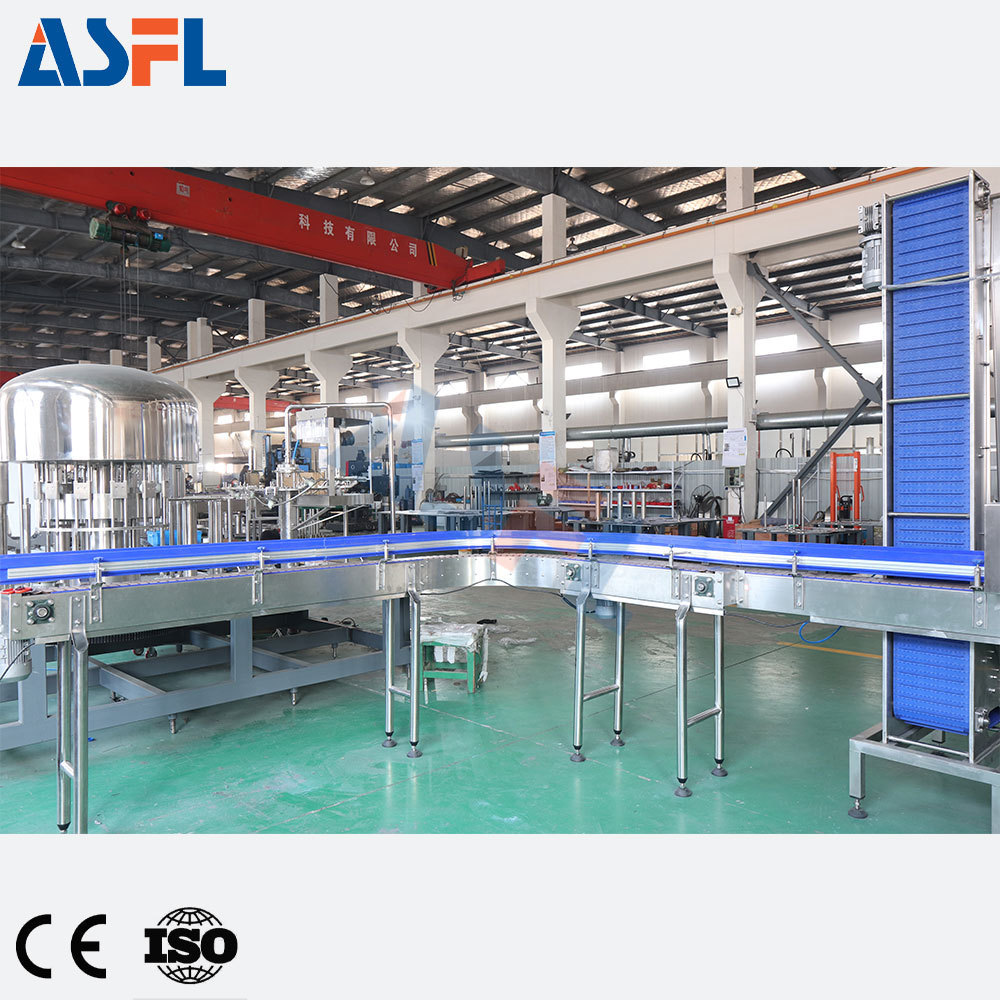

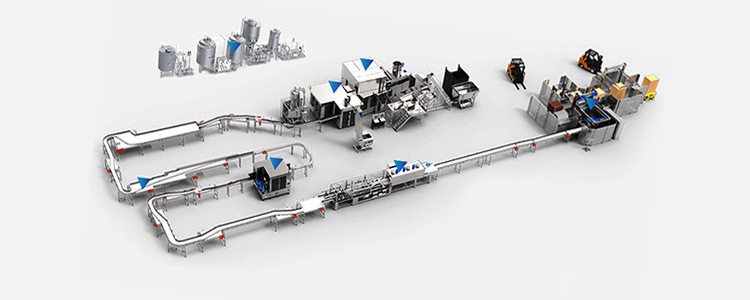

Pure water tank→Bottle blower→Air conveyor →Washing, filling & capping 3-in-1 filling machine→ Light check → Full-automatic labeling machine → Ink jet machine →Full automatic packing machine→ Warehouse

|

| 3-10L Rotary Type Big Bottle Water Filling Machine | ||||

| Model | CGF9-9-4 | CGF12-12-4 | CGF16-16-5 | CGF20-20-6 |

| Capacity(for 5L) | 1000-1200BPH | 2000-2200BPH | 3000-3200BPH | 4000-4500BPH |

| Suitable bottle shapes | PET circular or square | |||

| Bottle diameter(mm) | 50-115mm | |||

| Compressor air | 0.3-0.7Mpa | |||

| Washing meidium | Aseptic water | |||

| Rinsing pressure | >0.06Mpa <0.2Mpa | |||

| Total power (KW) | 4.24 | 5.03 | 6.57 | 8.5 |

| Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.2m | 4.7*3.2m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m |

| Weight(kg) | 2500kg | 3500kg | 4500kg | 7000kg |

| 3-10L Linear Type Big Bottle Water Bottling Machine | |||

| Model | CGF4-4-1 | CGF8-8-1 | CGF12-12-1 |

| Capacity(for 5L) | 400-500BPH | 800-1000BPH | 1200-1500BPH |

| Suitable bottle shapes | PET circular or square | ||

| Bottle diameter(mm) | 50-115mm | ||

| Compressor air | 0.3-0.7Mpa | ||

| Washing meidium | Aseptic water | ||

| Rinsing pressure | >0.06Mpa <0.2Mpa | ||

| Total power (KW) | 2.5 | 3.2 | 4.3 |

| Overall dimensions | 5*1.2*1.9M | 8*1.2*1.9M | 12*1.2*1.9 |

| Weight(kg) | 2500 | 3000 | 4000 |

A.Part one — Water Treatment System.

Water Treatment System.

* Raw water tank + Raw water pump

* Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

* Reverse Osmosis (one level)

* UV sterilizer

* Finished water tank + Pure water pump

B.Part two — Blow Molding Machine.

Blow Molding Machine.

* Blower : Industry-leading blower performance with patented control and self-regulation systems for repeatable and consistently high bottle quality

* Production flexibility: Up to 200 different equipment size configurations from one platform

* Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

* Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

* Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

C.Part three — Filling Part.

| Rinsing Part | Filling Part | Capping Part |

CGF Bottle Filling Machine.

* Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

* Optimum uptime: 30 % reduction in changeover and maintenance downtime

* Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

* Hygiene improvement through volume control and contactless filling

* Automatic dummy bottles: Safer, easier cleaning procedures

* Automatic bottle changeover improves uptime

D.Part Four — Labeling Part.

Labeling Machine.

There are PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label for choice.Our labeling machine has better performance, fast running, sustainable and high quality production.

E.Part five — Packing Parts.

Packing Machine.

According to customer requirements and market needs, we can provide better solutions for the packaging of the final product. The packaging machine has film shrinking machine and carton packaging for you to choose.

| Bottled Water | Hot Juice Tea | Carbonated Soft Drink | 5 Gallon Water | Glass Bottle | Can |