- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

BOZE355381

-

Product name:

-

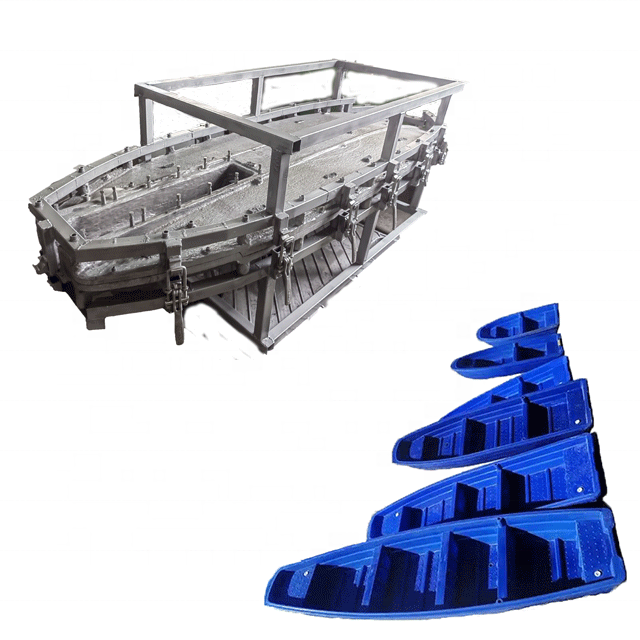

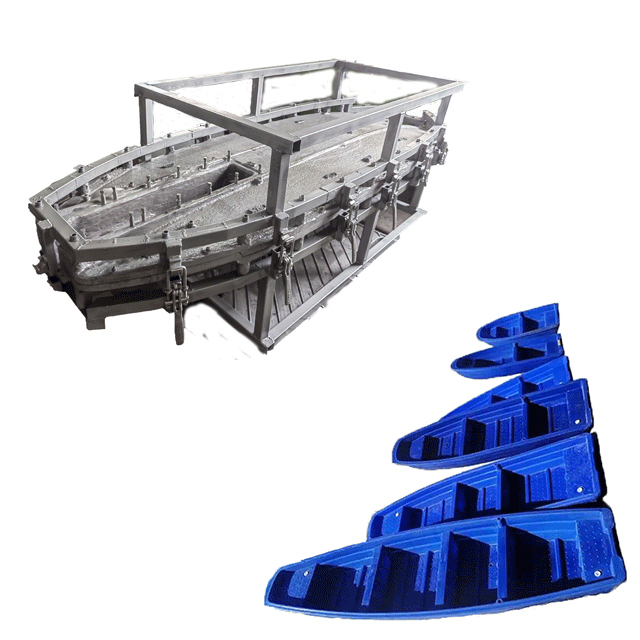

Plastic Boat Mold

-

Style:

-

for production used

-

Usage:

-

for

-

OEM:

-

Yes

-

Packing:

-

Carton

-

Size:

-

customized

-

Main material:

-

LLDPE

-

Application:

-

Home used

-

Material:

-

aluminum 6061

-

Package:

-

1 PC/CTNS

Quick Details

-

Shaping Mode:

-

CNC shaping

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BOZE

-

Model Number:

-

BOZE355381

-

Product name:

-

Plastic Boat Mold

-

Style:

-

for production used

-

Usage:

-

for

-

OEM:

-

Yes

-

Packing:

-

Carton

-

Size:

-

customized

-

Main material:

-

LLDPE

-

Application:

-

Home used

-

Material:

-

aluminum 6061

-

Package:

-

1 PC/CTNS

Product Description

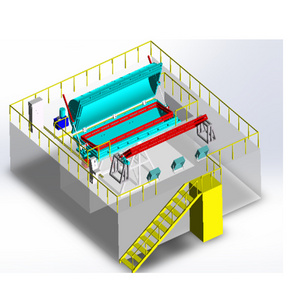

The production process of boat roll molding mold seems to be very simple, including mechanical equipment, mold and a whole set of materials;

However, the operation has quite high requirements for technology, including preheating, tumbling, cooling and discharging. The whole set depends entirely on the operator's estimation in terms of time, so no one knows whether a product is good or bad before it is really discharged.

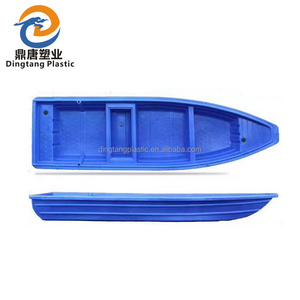

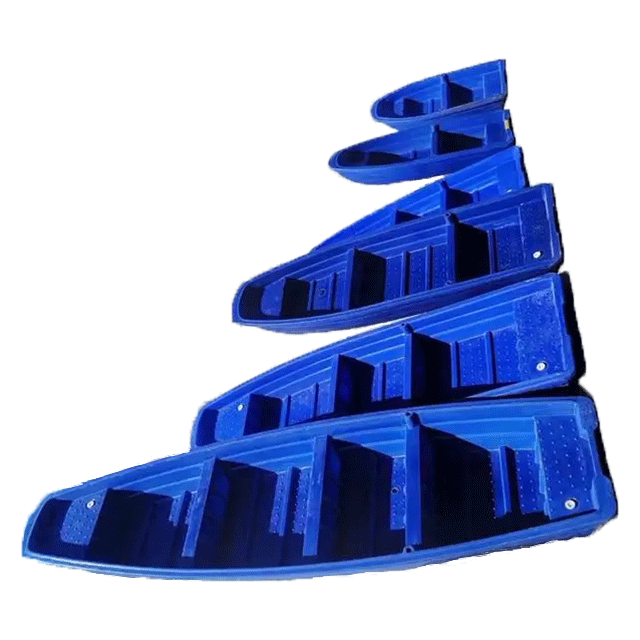

The levelness of the boat shall be measured first after the furnace is discharged. If it is found that the horizontal position is not at the center point, it shall be directly scrapped and cut on the spot. Then check the overall thickness, which is generally 3-4mm. There is no formal measuring instrument.

After cooling, evaluate the hand feeling and detect whether the thickness is uniform. If there is a particularly thin place or a hole, scrap it immediately. If one part is thinner than the other, but does not affect the use safety of the whole boat, do level B treatment. In addition, in case of bumping when the furnace is out, it belongs to class B boat when it can be repaired.

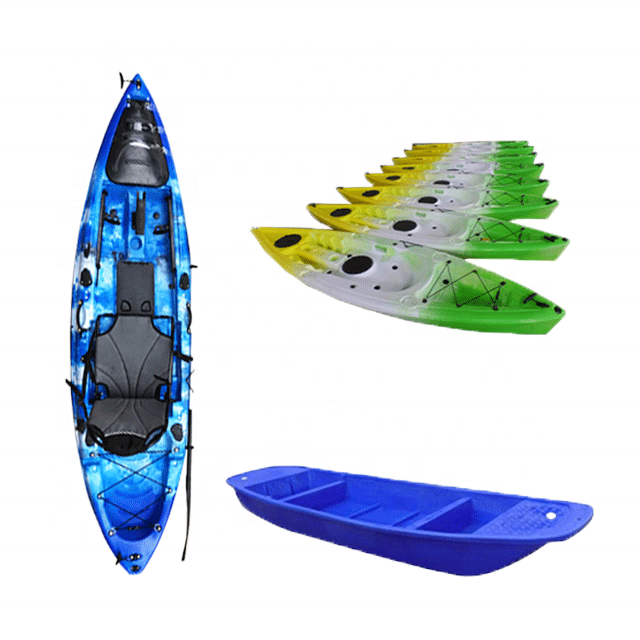

Rotational moulding or roto molding which is a kind of machining method used to make hollow seamless products of various sizes

and shapes, one piece parts such as large oil or chemical tanks, kayaks, point of purchase displays, frames, cases, furniture,

carts, dispensers, park equipment. The material can be UV resistant which can ensure the outdoor use of your products.

and shapes, one piece parts such as large oil or chemical tanks, kayaks, point of purchase displays, frames, cases, furniture,

carts, dispensers, park equipment. The material can be UV resistant which can ensure the outdoor use of your products.

|

Product name

|

Plastic Boat Mold

|

|

OEM

|

YES

|

|

Mold Material

|

Aluminum 6061

|

|

Product Material

|

PE

|

|

Size

|

customized

|

Successful case:

water tank , kayaks, incubators, plastic tool box, water tanks, fuel tanks, military boxes, plastic furniture and so on.

Hot Searches