- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

TITAN

-

Model Number:

-

Metal Profiles

-

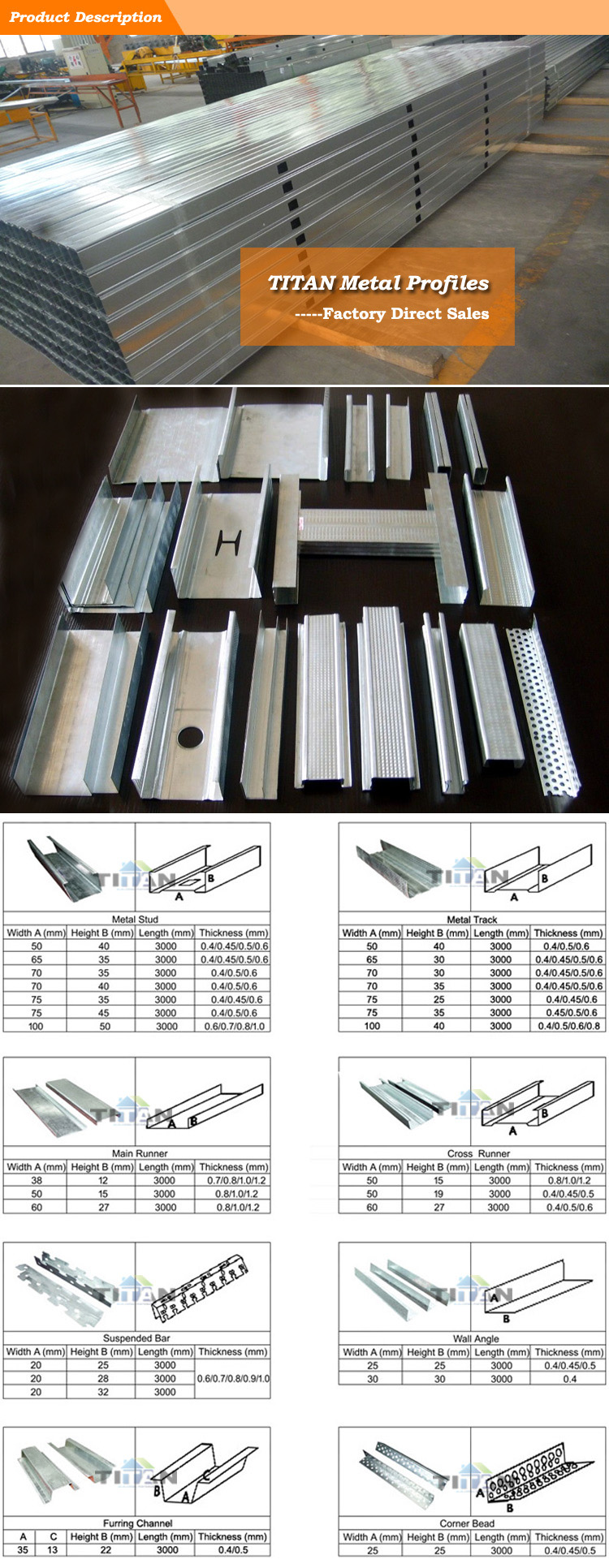

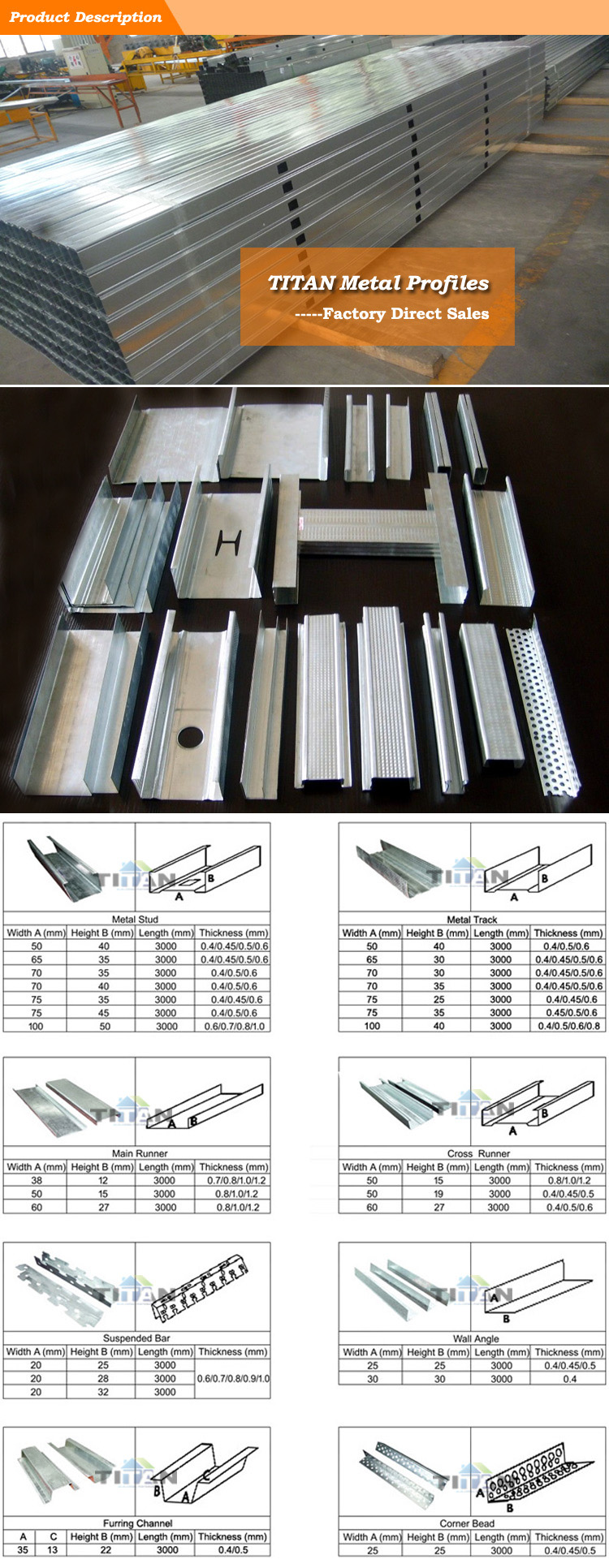

Product Name:

-

Metal Profiles

-

Raw Materials:

-

Galvanized Sheet,Galvanized Steel

-

Zine Coted:

-

GB:80g--275g; ASTM:G60-G90

-

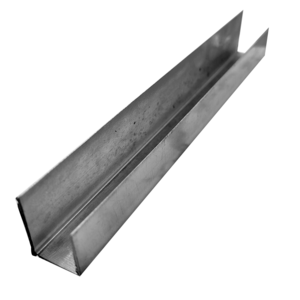

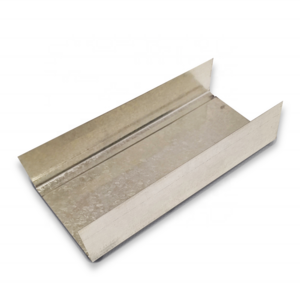

Height:

-

25/30/32/35/40mm

-

Width:

-

50/65/70/90/100mm

-

Thickness:

-

0.45~1.0mm

-

Perforated:

-

Is perforated or not

-

Function:

-

Fireproof, Waterproof, Rustproof, Heat Insulation,Smoke-proof

-

Certificate:

-

Ce

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

TITAN

-

Model Number:

-

Metal Profiles

-

Product Name:

-

Metal Profiles

-

Raw Materials:

-

Galvanized Sheet,Galvanized Steel

-

Zine Coted:

-

GB:80g--275g; ASTM:G60-G90

-

Height:

-

25/30/32/35/40mm

-

Width:

-

50/65/70/90/100mm

-

Thickness:

-

0.45~1.0mm

-

Perforated:

-

Is perforated or not

-

Function:

-

Fireproof, Waterproof, Rustproof, Heat Insulation,Smoke-proof

-

Certificate:

-

Ce

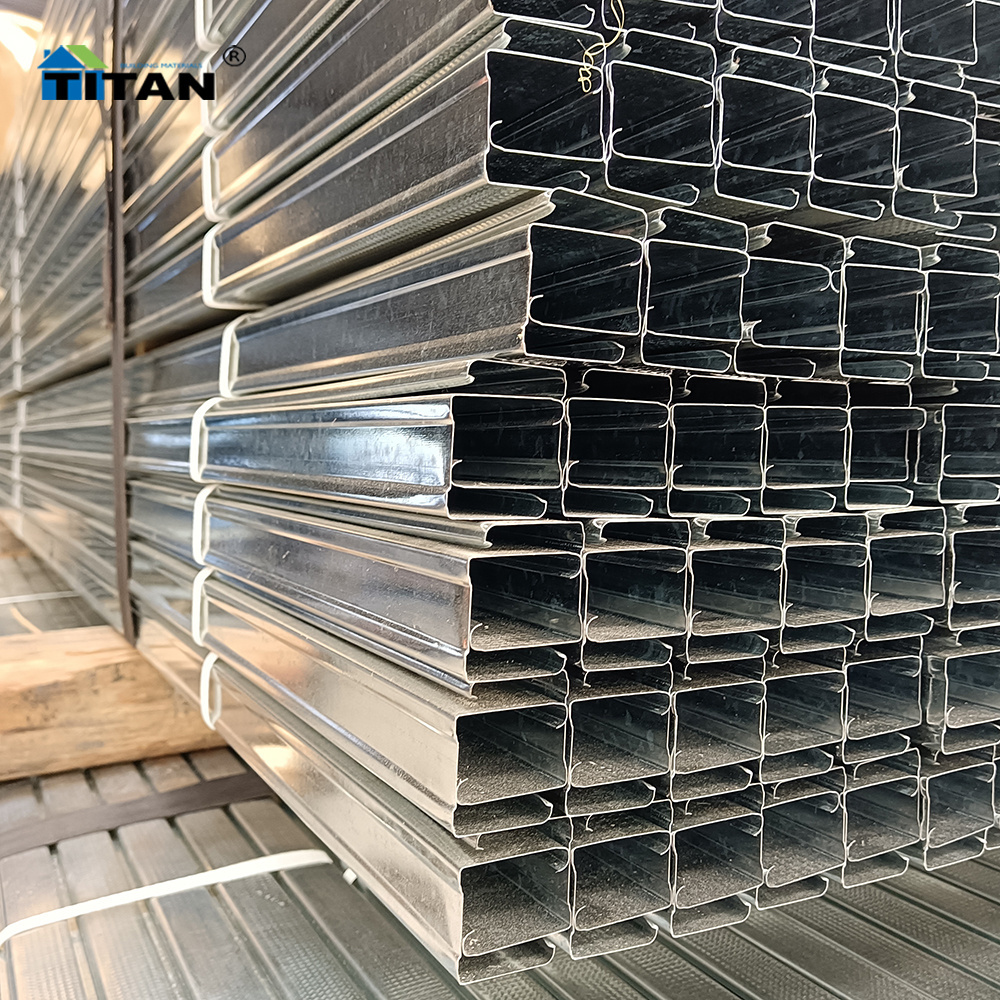

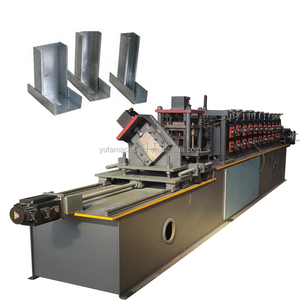

Galvanized steel drywall keel

1) Galvanized steel drywall keel is made of hot galvanized steel, including Stud, Track, C-Channel, Corner bead & accessories.

2) Galvanized steel drywall keel has light weight, high strength, fire resistance and noise reduciton features

3) Galvanized steel drywall keel will have perfect decorative effect with gypsum board ,calcium silicate boards and other

decorative materials.

4) It applies to public building, hotels and residential applications etc.

2) Galvanized steel drywall keel has light weight, high strength, fire resistance and noise reduciton features

3) Galvanized steel drywall keel will have perfect decorative effect with gypsum board ,calcium silicate boards and other

decorative materials.

4) It applies to public building, hotels and residential applications etc.

Main Characteristic

1.Galvanized Zinc coating will protect the channel from being rust;

2.Flexibility of application makes each ceiling tile/plasterboard easily installed anddisconnected;

3.Size adjustability can easier to match your request;

4.High quality leads longer life span & higher strength;

5.Better function of dealing with both high tensile stress and blending stress.

6. Easy and fast for installation,time-saving.

2.Flexibility of application makes each ceiling tile/plasterboard easily installed anddisconnected;

3.Size adjustability can easier to match your request;

4.High quality leads longer life span & higher strength;

5.Better function of dealing with both high tensile stress and blending stress.

6. Easy and fast for installation,time-saving.

Related Products

Partition Installing Method

1. Galvanized Metal Frame

a.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with

laterally supporting keel installed.

2. Board Material Package Fixed

a.Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b.Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally

about 200~250mm with screws sinking 0.5mm under the board face.

c.The expansion seam of about 4mm between boards should be kept.

d.The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously

to avoid generating inner stress to make board material bucking.

e.Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

a.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with

laterally supporting keel installed.

2. Board Material Package Fixed

a.Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b.Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally

about 200~250mm with screws sinking 0.5mm under the board face.

c.The expansion seam of about 4mm between boards should be kept.

d.The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously

to avoid generating inner stress to make board material bucking.

e.Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

Ceiling Installing Method

1.Carry out ceiling line-measuring to determine the ceiling’s fixed position, the boom’s central range is generally 1200.

2.Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3.Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4.Install the laterally supporting keel properly, its central ranges is 1224mm.

5.Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Notice:

The hanging system of TITAN board combined with light steel keel is divided into two kinds of person-standing type

and non person-standing type; for the non person-standing type,only consider the self-weight of ceiling and light.Lamp

without loading other loads; for the person-standing type. Consider about 80~100kg load when someone repaired it.

2.Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3.Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4.Install the laterally supporting keel properly, its central ranges is 1224mm.

5.Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Notice:

The hanging system of TITAN board combined with light steel keel is divided into two kinds of person-standing type

and non person-standing type; for the non person-standing type,only consider the self-weight of ceiling and light.Lamp

without loading other loads; for the person-standing type. Consider about 80~100kg load when someone repaired it.

|

Ceiling System Proportion

|

|

|

|

Gypsum Board 1200×2400×9mm

|

1 m2

|

|

|

Main Runner

|

1 m

|

|

|

Cross Runner

|

3~3.6 m

|

|

|

Hanger

|

2~3 pcs

|

|

|

Main Runner Connector

|

0.5 pcs

|

|

|

Cross Runner Connector

|

1 pcs

|

|

|

Leveling

|

4~6 pcs

|

|

|

Sleeve Anchor

|

1 set

|

|

|

Cross Screw

|

1 set

|

|

|

Drywall Self Tapping Screw

|

25~30 pcs

|

|

|

Paper Joint Tape / Mesh Joint Tape

|

1.5~2 m

|

|

|

Partition System Proportion

|

|

|

|

Gypsum Board 1200×2400×12mm

|

2 m2

|

|

|

Metal Stud

|

2.2~3.6 m

|

|

|

Metal Track

|

0.7~1.4 m

|

|

|

Intermediate Channel

|

0.8~1.4 m

|

|

|

Support Card

|

4 pcs

|

|

|

Drywall Self Tapping Screw

|

25~30 pcs

|

|

|

Paper Joint Tape / Mesh Joint Tape

|

1.5~2 m

|

|

Hot Searches