- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

300 Series

-

Surface Finish:

-

2B

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TORICH

-

Model Number:

-

ASTM B690 UNS N08367

-

Application:

-

Chemical industry

-

Outer Diameter:

-

273mm

-

Product name:

-

Iron Nickel Chromium Molybdenum Alloys Seamless Pipe and Tube

-

Shape:

-

Round.square.Rectangular

-

Material:

-

UNS N08367 Al-6XN

-

Keyword:

-

Staninless Steel Pipe

-

Technique:

-

Cold Rolled Hot Rolled

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

-

Usage:

-

Chemical industry

-

MOQ:

-

1Ton

-

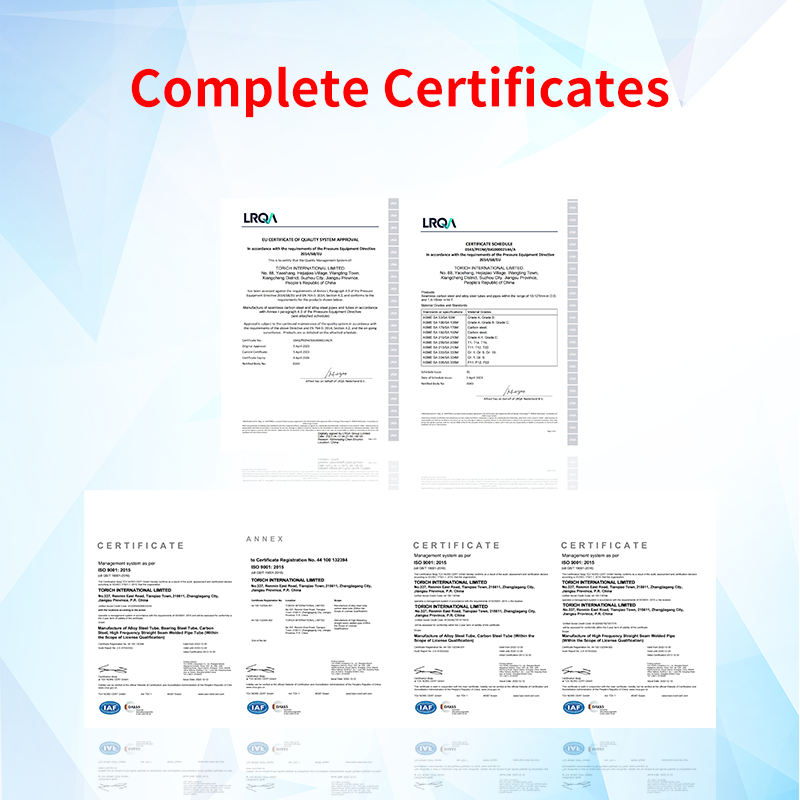

Certification:

-

ISO9001:2015

-

Packing:

-

Standard Seaworthy Package

Quick Details

-

Type:

-

Seamless

-

Steel Grade:

-

UNS N08367, Al-6XN

-

Tolerance:

-

±1%

-

Grade:

-

300 Series

-

Surface Finish:

-

2B

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TORICH

-

Model Number:

-

ASTM B690 UNS N08367

-

Application:

-

Chemical industry

-

Outer Diameter:

-

273mm

-

Product name:

-

Iron Nickel Chromium Molybdenum Alloys Seamless Pipe and Tube

-

Shape:

-

Round.square.Rectangular

-

Material:

-

UNS N08367 Al-6XN

-

Keyword:

-

Staninless Steel Pipe

-

Technique:

-

Cold Rolled Hot Rolled

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

-

Usage:

-

Chemical industry

-

MOQ:

-

1Ton

-

Certification:

-

ISO9001:2015

-

Packing:

-

Standard Seaworthy Package

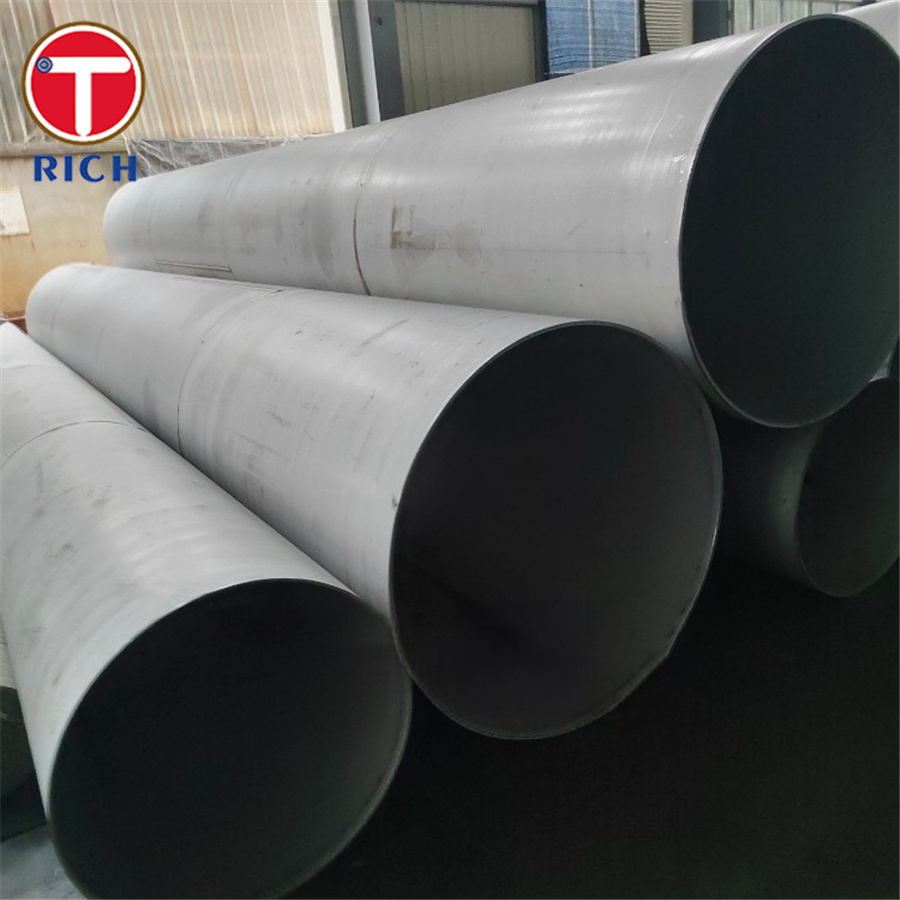

ASTM B690 UNS N08367 Iron Nickel Chromium Molybdenum Alloys Seamless Pipe and Tube For Chemical Industry

Material

The ASTM B690 UNS N08367 is a type of iron nickel chromium molybdenum alloy that is specifically designed for use in the chemical industry. This alloy offers excellent resistance to corrosion, making it suitable for applications where exposure to harsh chemicals is common. The material is known for its high strength and durability, making it an ideal choice for demanding environments.

Specification

The ASTM B690 specification outlines the requirements for seamless pipes and tubes made from UNS N08367 alloy. It provides guidelines for the chemical composition, mechanical properties, and dimensions of the pipes and tubes. This specification ensures that the material meets the necessary standards for use in the chemical industry.

Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 24.0 - 26.0 |

| Chromium (Cr) | 19.0 - 21.0 |

| Molybdenum (Mo) | 6.0 - 7.0 |

| Iron (Fe) | Balance |

| Manganese (Mn) | 1.0 - 2.0 |

| Silicon (Si) | 0.30 - 0.80 |

| Copper (Cu) | 0.50 - 1.00 |

| Nitrogen (N) | 0.20 - 0.40 |

| Carbon (C) | 0.030 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 690 MPa (min) |

| Yield Strength (0.2% offset) | 345 MPa (min) |

| Elongation | 40% (min) |

| Hardness | HRB 95 (max) |

| Density | 7.8 g/cm³ |

| Melting Range | 1350-1375°C |

Application

The ASTM B690 UNS N08367 alloy seamless pipes and tubes find extensive application in the chemical industry. Due to their exceptional resistance to corrosion, they are used in various chemical processing units, including reactors, heat exchangers, and piping systems. This alloy is particularly suitable for environments where exposure to corrosive chemicals such as sulfuric acid, hydrochloric acid, and phosphoric acid is prevalent.

The high strength and durability of this alloy make it a reliable choice for applications where reliability and longevity are crucial. Its resistance to pitting, crevice corrosion, and stress corrosion cracking further enhance its suitability for chemical industry applications.