Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HUILI

-

Voltage:

-

different

-

Dimension(L*W*H):

-

different

-

Power (kW):

-

30

-

Weight:

-

KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

plastic corrugated pipe machine

-

Raw material:

-

PE

-

Color:

-

Customer Choice

-

Usage:

-

plastic corrugated pipe

-

electrical equipment:

-

World famous brand

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

plastic pipe

-

pipe diameter:

-

10-800 mm

-

Inverter:

-

ABB Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

34.5 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HUILI

-

Voltage:

-

different

-

Dimension(L*W*H):

-

different

-

Power (kW):

-

30

-

Weight:

-

KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

plastic corrugated pipe machine

-

Raw material:

-

PE

-

Color:

-

Customer Choice

-

Usage:

-

plastic corrugated pipe

-

electrical equipment:

-

World famous brand

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

plastic pipe

-

pipe diameter:

-

10-800 mm

-

Inverter:

-

ABB Brand

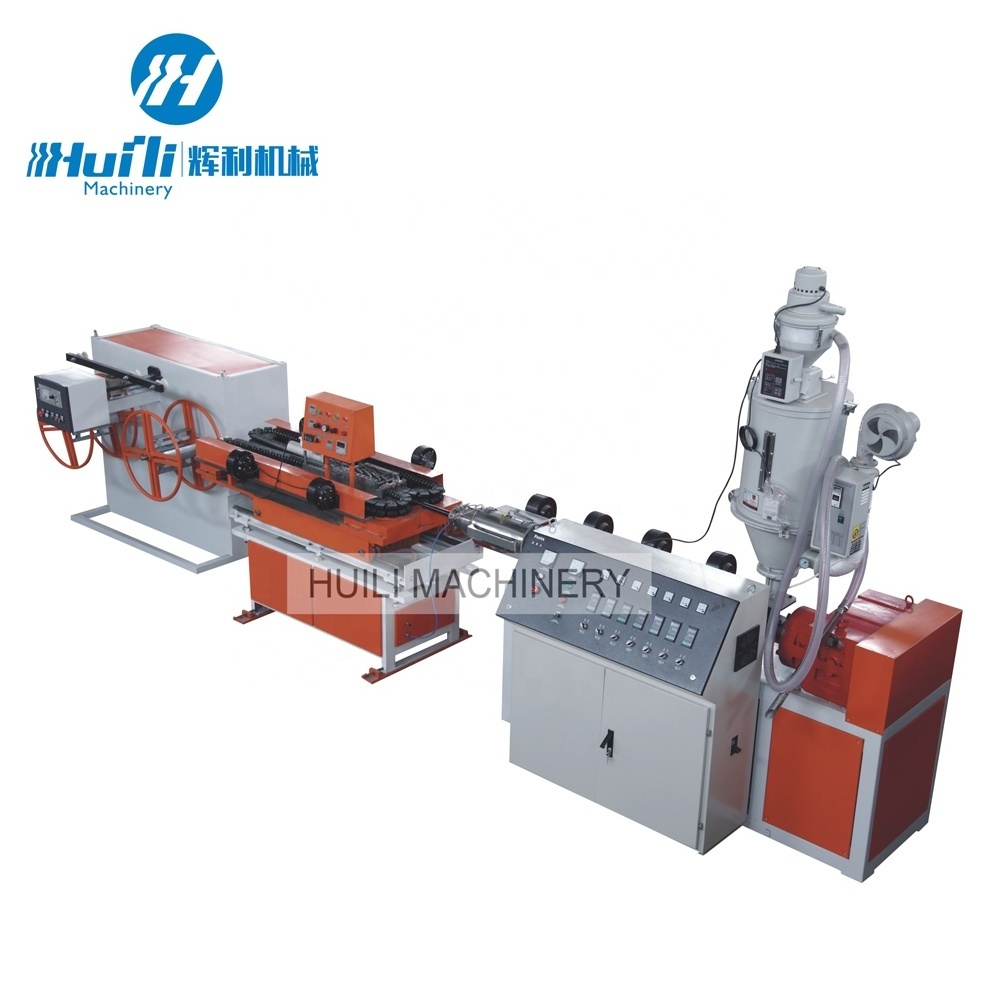

PE/PP/PVC Electrical Cable Passing the Hose Production Line / Corrugated Pipe Making Machine

extrusion line/ corrugated pipe production line

Working flow of PE, PP, PVC single/double wall corrugated pipe machine/ corrugated pipe extrusion line/ corrugated pipe production line

Plastic extruder → mould → forming machine →pull off machine → wind er

Application:

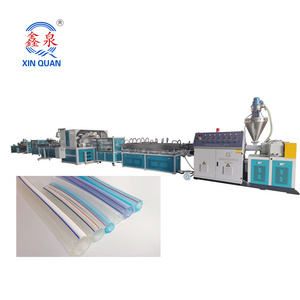

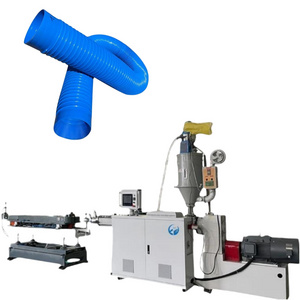

The single wall corrugated pipe are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc. . It is widely used both at home and abroad as it is an easy and reliable coupling without any complex fitting, and replaces the concrete pipe and cast iron pipe. At present, PE double wall corrugated piping is being used extensively to ensure the development of environmental protection during networking of water and sewerage .

|

1. P lastic extruder (see below)

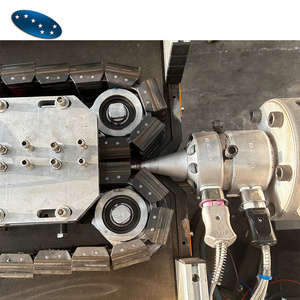

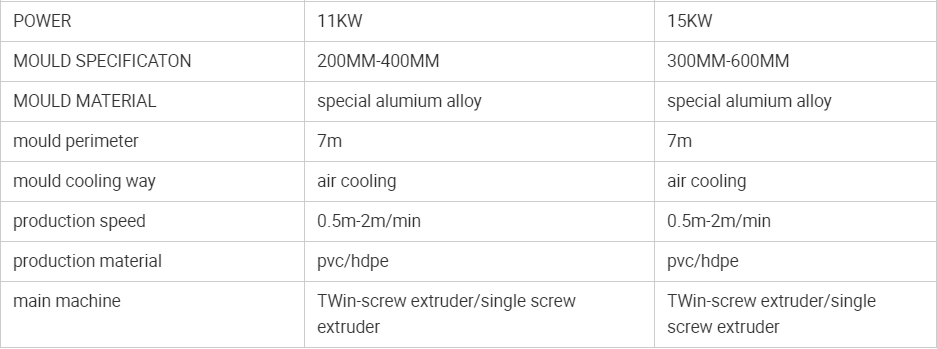

2. mould (see below)

3.Corrugating machine (see below)

4.pull off machine (see below)

5.winder (see below)

PE / PP /PVC pipe production line