IV. The use of compressors.

1. Preparation before starting the compressor:

①Whether the lubricating oil in the crankcase of the compressor is added to the position above the scale line of the oil sight window.

②Whether the system valve is in the correct position.

③Check whether all parts of the compressor are connected reliably, and only after the compressor and the entire system are normal, can it be turned on.

④ Before starting the compressor for the first time, check whether the electrical wiring of the motor and starter is correct, turn the large pulley by hand, and observe whether there is any error. After confirmation, start the motor.

V. Start-up and operation of the compressor:

①After the compressor is running, the vibration and sound of the unit should be observed. If there is any abnormality, it should be shut down for inspection.

②Check whether the compressor's inlet and outlet pressures and inlet and outlet temperatures meet the specified parameters. When the compressor is working, the difference between the inlet and outlet pressures

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1250*640*540mm

-

Capacity:

-

0

-

Weight:

-

200

-

Inner Material:

-

Carbon steel

-

Outer Material:

-

Carbon steel

-

Design Pressure(MPa):

-

2.5

-

Design Standard:

-

GB T150 ISO9001

-

Working Temperature(℃):

-

-40 - 50 ℃

-

Name:

-

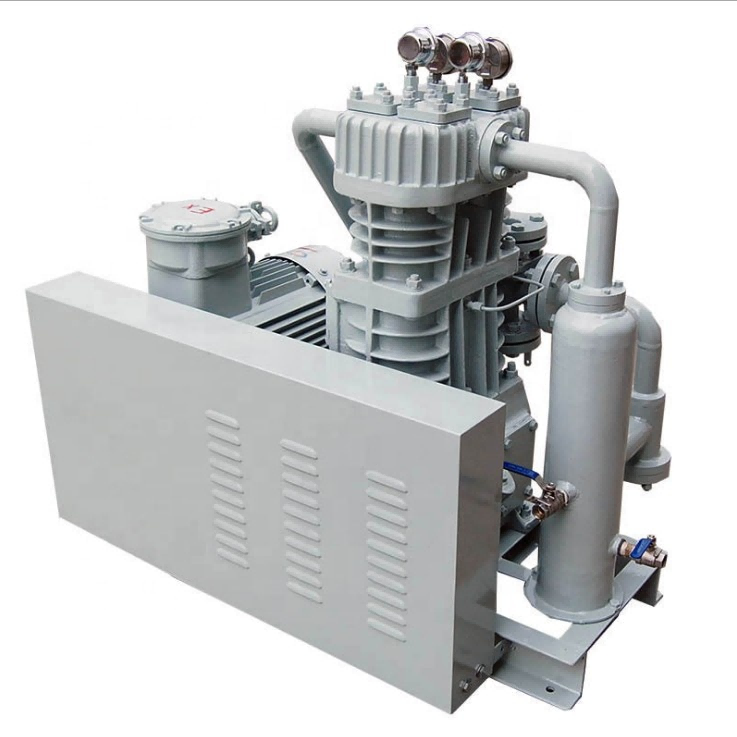

LPG compressor For petroleum propane butane

-

Application:

-

LPG filling plant

-

Filling medium:

-

Lpg/propane

-

Usage:

-

Used for transfer gas

-

Working pressure:

-

2.5Mpa

-

Package:

-

Wooden

-

MOQ:

-

1

-

Advantage:

-

Long sercie life

-

Keyword:

-

Lpg Gas Compressor Cng Compressor For Filling Station

Quick Details

-

Max Working Pressure(MPa):

-

2.52 MPa

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHD

-

Dimension(L*W*H):

-

1250*640*540mm

-

Capacity:

-

0

-

Weight:

-

200

-

Inner Material:

-

Carbon steel

-

Outer Material:

-

Carbon steel

-

Design Pressure(MPa):

-

2.5

-

Design Standard:

-

GB T150 ISO9001

-

Working Temperature(℃):

-

-40 - 50 ℃

-

Name:

-

LPG compressor For petroleum propane butane

-

Application:

-

LPG filling plant

-

Filling medium:

-

Lpg/propane

-

Usage:

-

Used for transfer gas

-

Working pressure:

-

2.5Mpa

-

Package:

-

Wooden

-

MOQ:

-

1

-

Advantage:

-

Long sercie life

-

Keyword:

-

Lpg Gas Compressor Cng Compressor For Filling Station

Products Description

LPG compressor

I. Power installation

The compressor is installed on the foundation, and the electrician selects the cable specifications according to the specified standards, and connects the power cables according to the requirements of the explosion-proof motor manual, and also effectively connects the ground wire.

The user can equip the explosion-proof starter according to the power (kw) of the explosion-proof motor.

II. Connection and installation of pipeline and compressor

Connect the gas phase pipeline to the upper and lower flanges of the two-position four-way valve. When the handle of the two-position four-way valve is in the (I) position (positive position), the lower flange of the two-position four-way valve is the gas phase inlet and the upper flange is the gas phase outlet, that is, low inlet and high outlet. When the handle is in (Ⅱ) position (reverse position), the gas flow direction is high in and low out.

III. Vent installation

①Connect the discharge port of the safety valve to the outdoors with a pipe, so that when the safety valve is opened, the exhaust gas can be led to the outdoors and emptied.

②Using the G1/2 pipe to lead the outlet of the drain valve under the gas-liquid separator to the outdoor for emptying.

③Use a hose to connect to the filler vent and lead it to the outside for venting.

Details Images

Product Parameter

|

LPG compressor manual

|

|

|

|

INTERNALFLANGE

|

|

||||

|

|

A

|

B

|

C

|

D

|

D

|

||||

|

ZW-0.4/10-15-A

|

170

|

1300

|

310

|

500

|

480

|

||||

|

ZW-0.5/10-15-A

|

|

|

|

47

|

21.7

|

||||

|

ZW-0.6/10-15-A

|

|

|

|

53

|

23

|

||||

|

ZW-0.8/10-15-A

|

|

|

|

55

|

23.8

|

||||

|

ZW-0.4/10-15-B

|

170

|

1300

|

345

|

600

|

480

|

||||

|

ZW-0.5/10-15-B

|

225

|

|

|

53

|

26.5

|

||||

|

ZW-0.6/10-15-B

|

240

|

|

|

56.5

|

27.8

|

||||

|

ZW-0.8/10-15-B

|

250

|

|

|

59

|

28.7

|

||||

|

ZW-0.95/10-15-C

|

170

|

1300

|

400

|

800

|

480

|

||||

|

ZW-1.0/10-15-C

|

225

|

|

|

54

|

30.0

|

||||

|

ZW-1.2/10-15-C

|

235

|

|

|

57

|

31.5

|

||||

|

ZW-1.5/10-15-C

|

240

|

|

|

58.5

|

32.5

|

||||

|

ZW-1.6/10-15-C

|

250

|

|

|

61.5

|

34.0

|

||||

Our Company

ANYANG SANHUANGDING METAL MATERIALS CO.,LTD is an international foreign trade export company, is located in Anyang City, Henan Province. The company currently has 40 employees in the International Foreign Trade Department, including more than 20 sales in the Foreign Trade Department, 8 in the Foreign Trade Operations Department, 4 in the Purchasing Department, and 5 in the engineering and technical personnel. 3 Persons in documentary. Our company technology, strong capital, and complete quality assurance system.

We got ISO quality and environmental certification, quality problems in production can be tracked and forth to ensure the quality of the pressure vessel is controlled. With standardized management, professional design, scientific and quality construction to achieve efficient use of consumers.

Certifications

Project

our products have been exported to 32countries around the world and well received bycustomers.If we received any questions formcustomers.we will reply and give our customerssolution within 24 hours.

Packing & Delivery

Our company has strong economic strength, perfect technology and equipment, strong new product development capability, and has more than 180 processing equipments.The equipment has a lifting capacity of 100T and an annual production capacity of 10,000 tons.

Hot Searches