- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Various

-

Grinding surface:

-

Ral.6

-

Shape:

-

A/C/D/E/G/H/K/L/M/N

-

Material:

-

Tungsten carbide

-

Overall Length:

-

38MM-150MM

-

Name:

-

Top Qaulity Carbide Rotary Burr Carbide Rotary File

-

Sample:

-

Available

-

Hardness:

-

UP to HRC90

-

Shank Dia:

-

1/8"--3/8"OR 3.0MM-9.0MM

-

Tooth Type:

-

Standard Cut/Double Cut/DIamont cut ect.

-

Application:

-

Steel

Quick Details

-

Warranty:

-

No

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LISU

-

Model Number:

-

Various

-

Grinding surface:

-

Ral.6

-

Shape:

-

A/C/D/E/G/H/K/L/M/N

-

Material:

-

Tungsten carbide

-

Overall Length:

-

38MM-150MM

-

Name:

-

Top Qaulity Carbide Rotary Burr Carbide Rotary File

-

Sample:

-

Available

-

Hardness:

-

UP to HRC90

-

Shank Dia:

-

1/8"--3/8"OR 3.0MM-9.0MM

-

Tooth Type:

-

Standard Cut/Double Cut/DIamont cut ect.

-

Application:

-

Steel

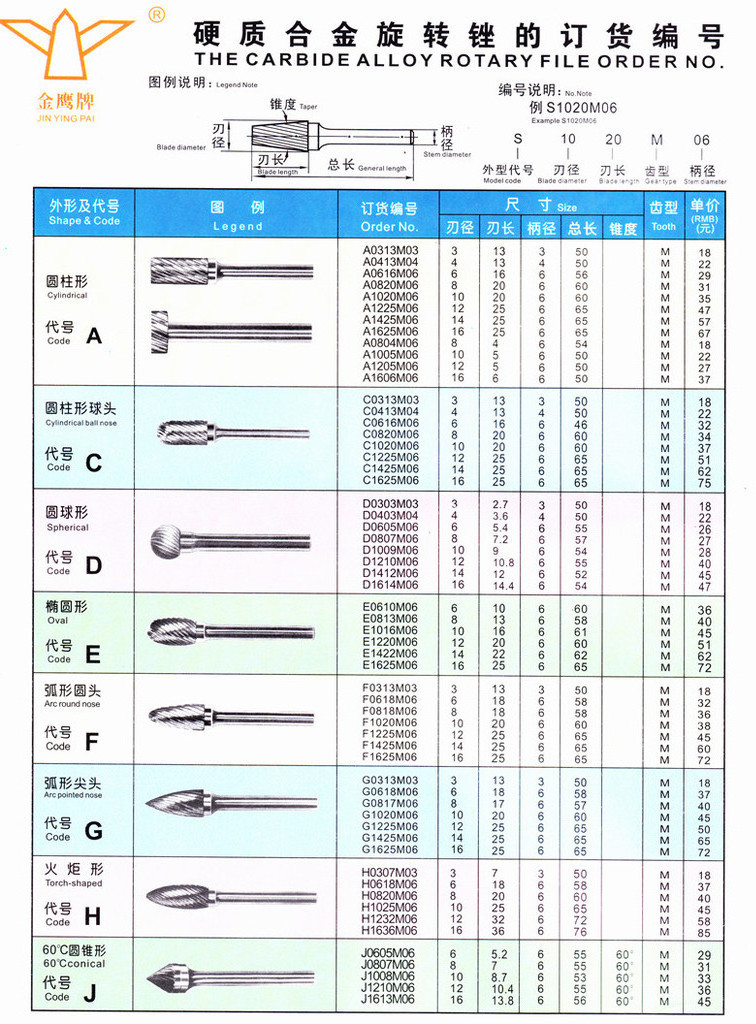

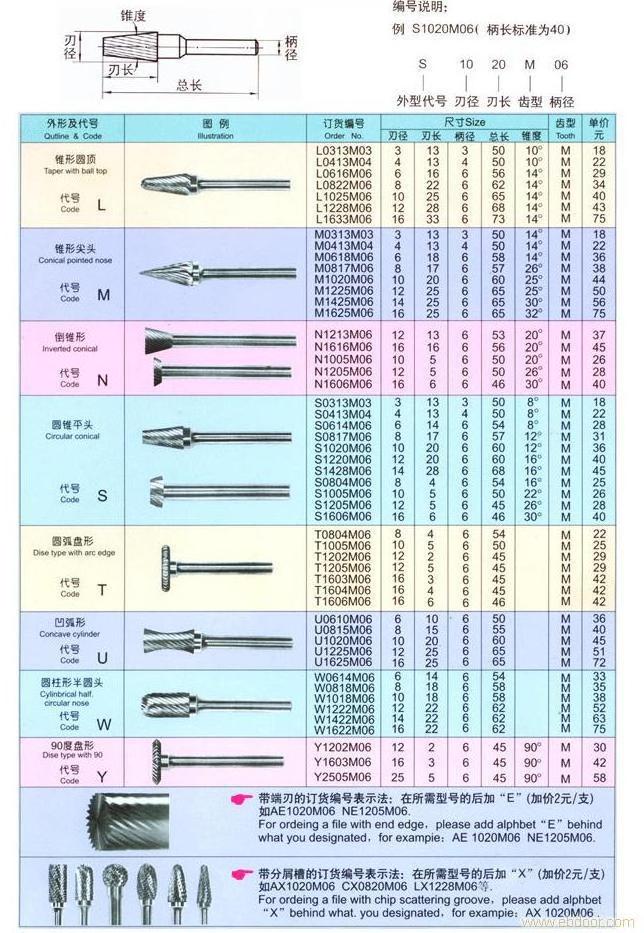

Top Quality Carbide Rotary Burrs Carbide Rotary Files

1. Product specifications:

|

Material

|

Tungsten Carbide |

| Sizes | Shank dia:3mm,4mm,6mm;blade dia/blade length/overal length:standard/as request |

|

Processing hardness

|

HRA≥85

|

|

Grinding surface |

Ral.6 |

|

Abrasive processing

|

Process metal/nonmetal products with hardness less than HRC70

|

| Usage |

The carbide alloy rotary file use is extremely widespread,appies in the mold processing manufature .Machine parts bevel edge ,inverted round and trench processing ,the clean-up casting ,foreiging,weldment's edge,burr and welded joint;pipeline,impeller passage's light entire processing ,metal and nonmentallic naterial (bone jade stone )industrial art carving .

|

| Shape |

Cylinder, cylindrical ball nose, spherical, oval, arc round nose, arc pointed nose, torch-shaped, 60°C conical, 90°C conical, Taper with round top,conical pointed nose,inverted conical, cone flat nose, Dise type with arc edge,Concace arc shape, columni form with half round nose, Dise type of 90 degree, etc

|

2.The main features of our carbide rotary file :

1. The carbide alloy rotary file is the fitter and mold labor's indispensable advanced too,its characteristic is substitutes for the belt handle small grinding wheel and the non-dust pollution

the service life is equal to several hundred belt hnadle grinding wheel .

2.High production efficiency. Dozens of times more efficiency than the manual file, and nearly ten times more efficiency than the small handle grinding wheel.

3.It can process cast iron, cast steel, carbon steel, alloy steel, stainless steel, copper, aluminum and other metal products, and process marble, jade, bone and other nonmetal products.

Processing hardness can be HRA≥85.

4.process a variety of chamfer, rounding, groove & key slot of the mechanical parts; clean the tube; fine finish the internal surface of mechanical parts, such as machinery factory, workshop, etc.

5. The processing efficiency enhances above 5 times ,below abrasive machining degree of hardness HRC70 each metal,grinding surface rounghness may reach Ral.6 ,convenience grasps,use to be simple ,safe reliable,reduces the arduous manual labor greatly ,reduce the cost of production .

3. The more pictures of the Carbide Rotary Burrs for your reference:

4.Matter needing attention :

1.The supporting drive tool's fixture concentricity should be well.it is supporting use with the not concentric fixture, using stem must clamp and correct.

2.The sloshing phenomenon is strictly prohibited while it is operating,the cutting direction should move smoothly from right to left,don't force excessive to prevent bounce and bump.

3.If the handle length surpasses 80mm should decelerate the operation to prevent the chip flying ,please protetive glasses .

| Shipping | we use DHL,UPS,FEDEX ect .to ship the godds ,or accordding to the customer's requirment . |

| Delivery time | about 3-7 days,for special time according to your quantity! |

| Packing | Carton ,plastic bag,or as your request |

5.Our service :

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or designs.

6.About us

1. Lishuo Hardware Mould Components company was established in 2000 and Located at Chang'An town,DongGuan City,GuangDong Province.

2.We have a complete set of quality assurance system and management system to ensure that the mechanical properties of the product and service could achieve to the first level .

7. Any products you have interest ,pls feel free to contact me at any time