Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACC FRIEND

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

40000*4000*2800

-

Power (kW):

-

37

-

Weight:

-

10000 KG

-

Raw material:

-

PVC Powder

-

Processing Type:

-

Extruding Equipment

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Unapplicable

-

Screw Speed (rpm):

-

37 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACC FRIEND

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

40000*4000*2800

-

Power (kW):

-

37

-

Weight:

-

10000 KG

-

Raw material:

-

PVC Powder

-

Processing Type:

-

Extruding Equipment

Product Description

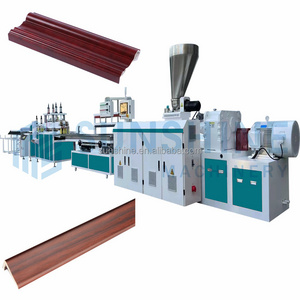

PVC decorative wall board extrusion machine line

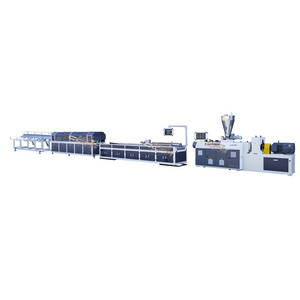

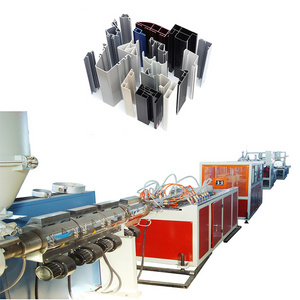

1. PVC profile extrusion production line is a specialized machinery used for manufacturing PVC profile/board

2. This production line is designed to efficiently and accurately extrude PVC materials into board with consistent quality.

3. The extrusion process involves melting and mixing Caco3 or flour with plastic polymers, such as PVC or PE, to create a homogeneous PVC comppound material.

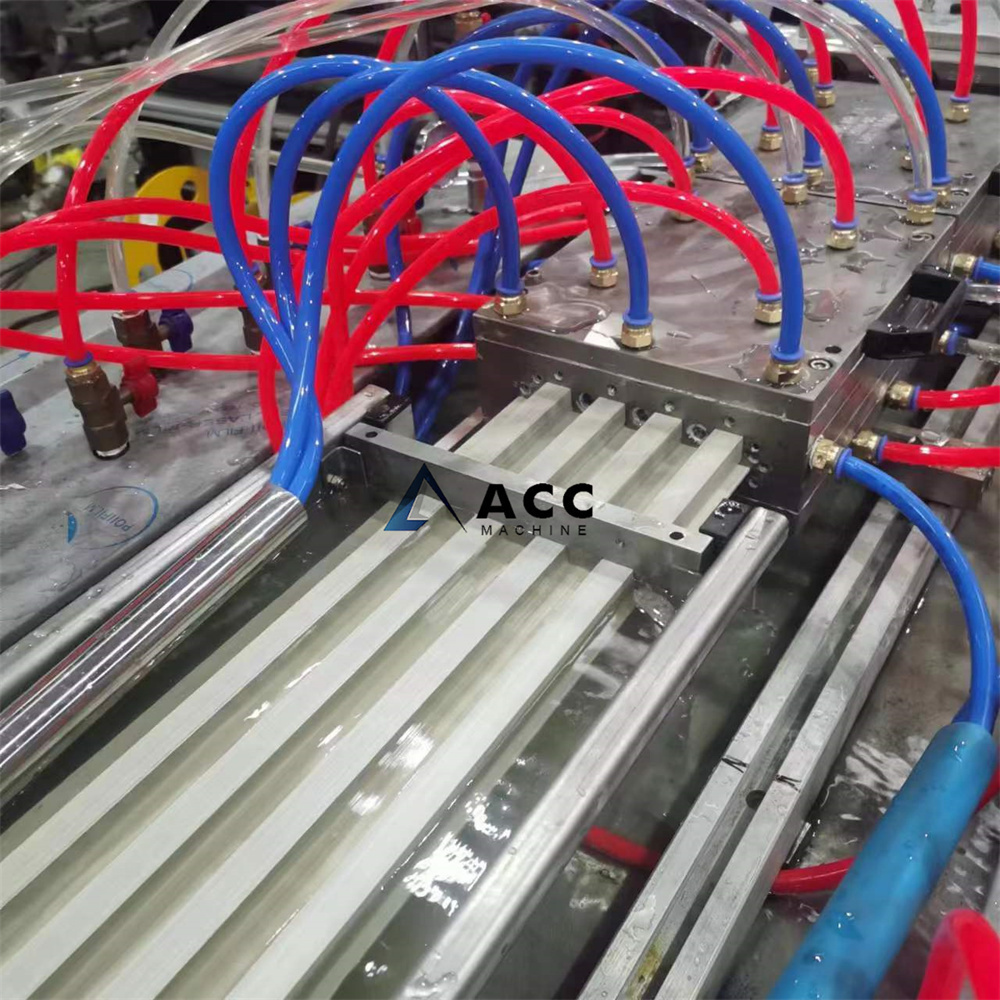

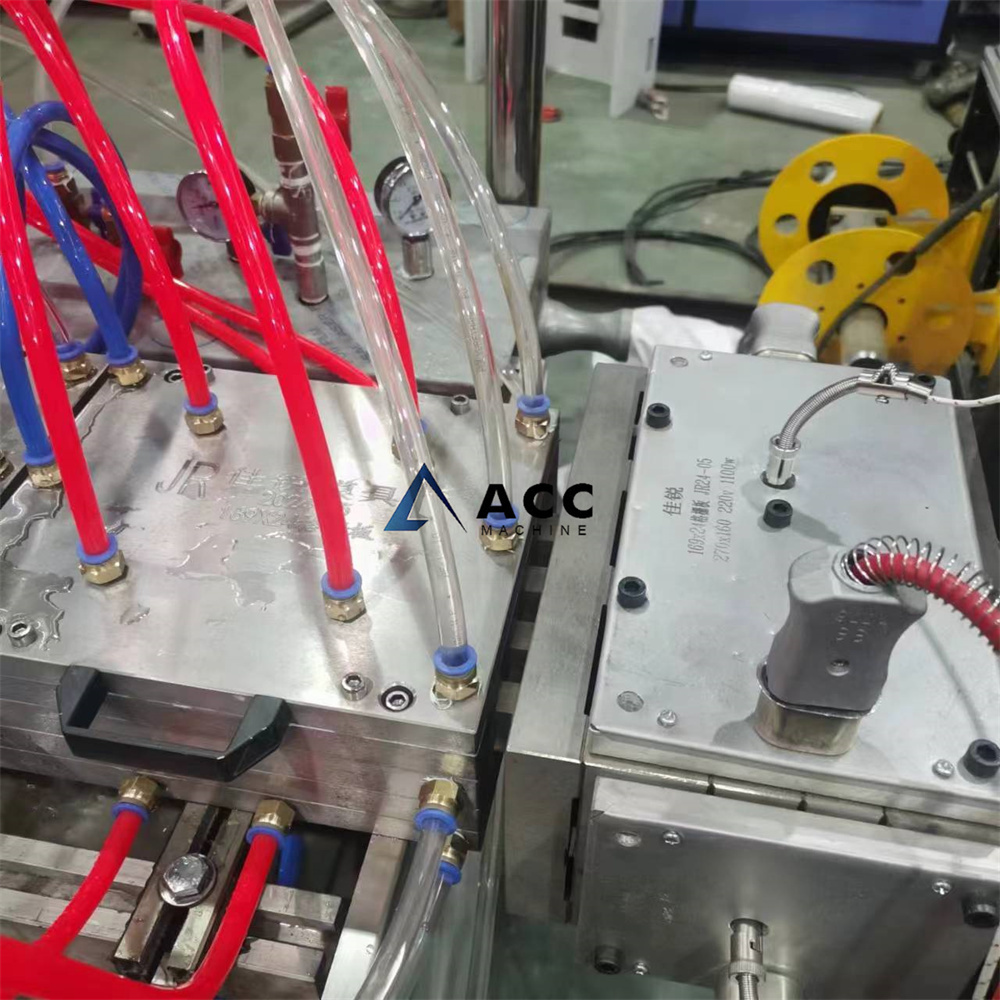

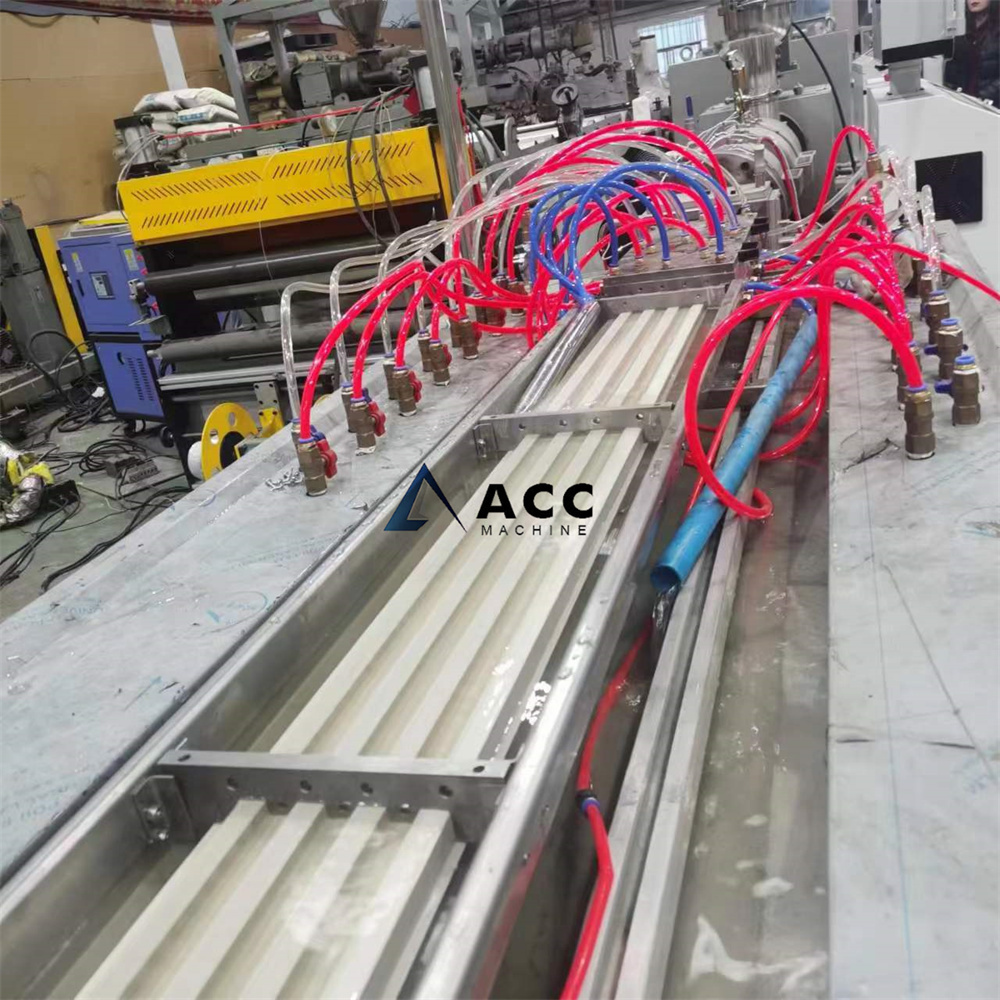

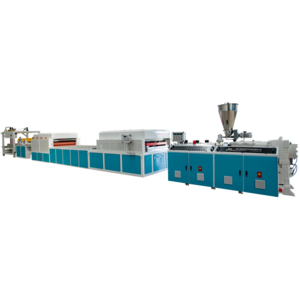

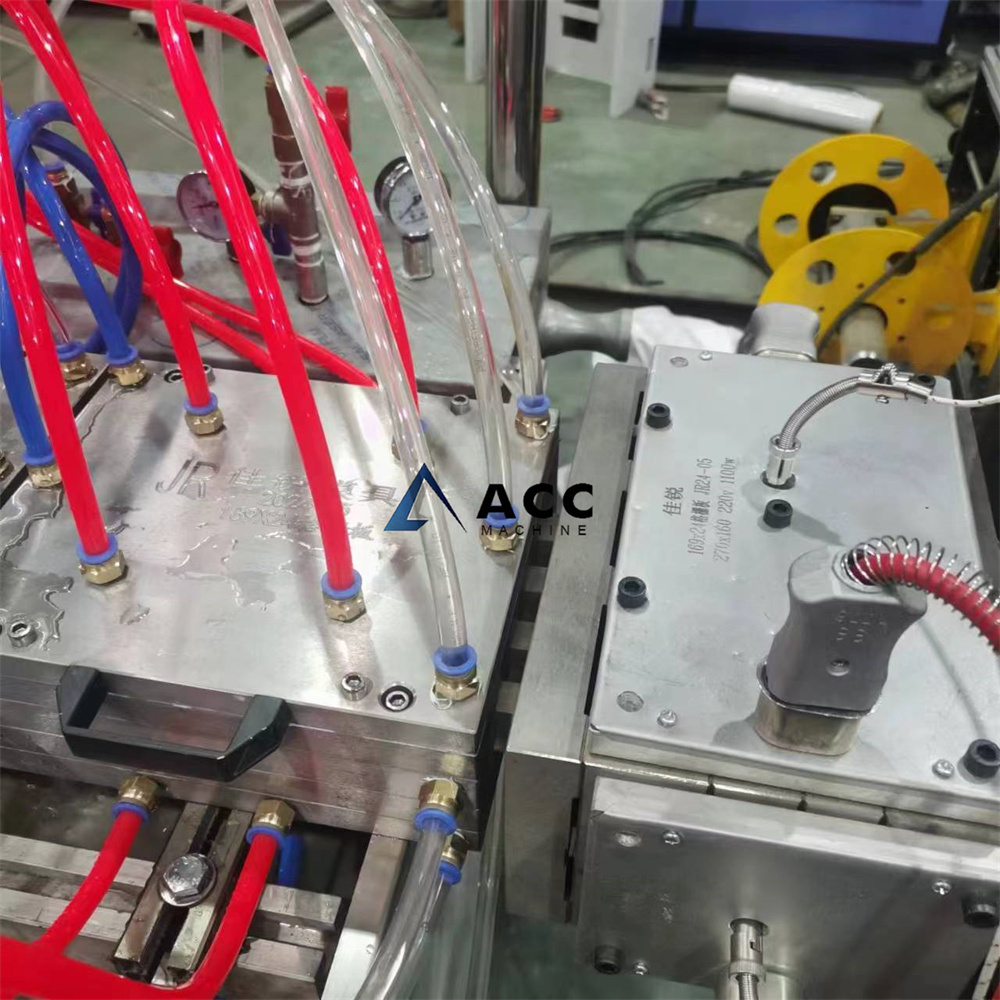

4. The PVC board extrusion production line typically consists of a twin-screw extruder, a cooling system, a shaping tool, and a cutting device.

5. The twin-screw extruder plays a crucial role in heating, mixing, and compressing the PVC material for extrusion.

6. The cooling system helps to quickly cool down the extruded PVC board, ensuring their dimensional stability and preventing deformation.

7. The shaping tool is responsible for giving the door panels their desired shape, texture, and surface finish.

8. Finally, the cutting device accurately cuts the extruded door panels into desired lengths.

9. The PVC board extrusion production line is highly automated, allowing for efficient and continuous production with minimal manual intervention.

10. This production line is widely used in the construction industry for manufacturing durable, weather-resistant, and eco-friendly PVC board

Machines are all customized according to clients offered PVC profile samples )

The complete production line including:

|

1

|

powder screw loading machine

|

|

2

|

SRL-Z series high speed mixing unit

|

|

3

|

screw loading machine

|

|

4

|

SJSZ65/132 80/156 model conical twin screw extruder

|

|

6

|

PVC WPC board

|

|

7

|

vacuum calibration table

|

|

8

|

haul off machine/traction

|

|

9

|

cutting machine

|

|

10

|

stacker

|

|

optional

|

crusher machine

|

|

optional

|

miller/pulverizer/grinding machine

|

Parts

ABB/DETLA frequency inverter

PLC touch screen control

Omron temperature control

Packing & Delivery

wooden case packed, 20GP, 40GP/HQ container .

Hot Searches