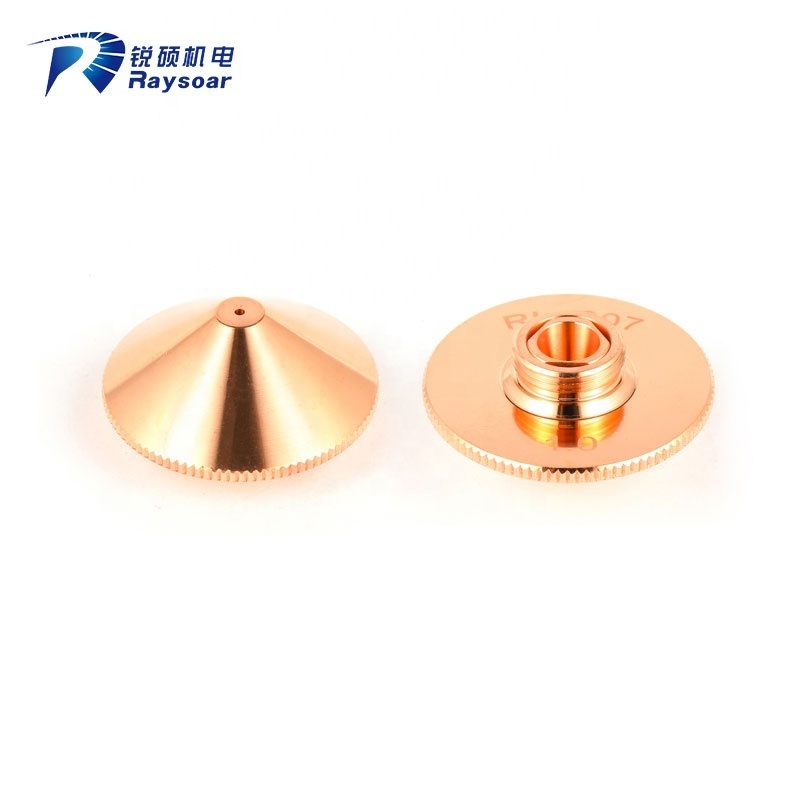

The single-layer tapered air passage is more conducive to the passage of large flow of gas, mainly using high-pressure nitrogen or air to achieve the melting and cutting of stainless steel, aluminum alloy and carbon steel.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Raysoar

-

Weight (KG):

-

0.05 KG

-

Application:

-

Industrial laser cutting head

-

Keywords:

-

Laser cutting nozzle

-

Material:

-

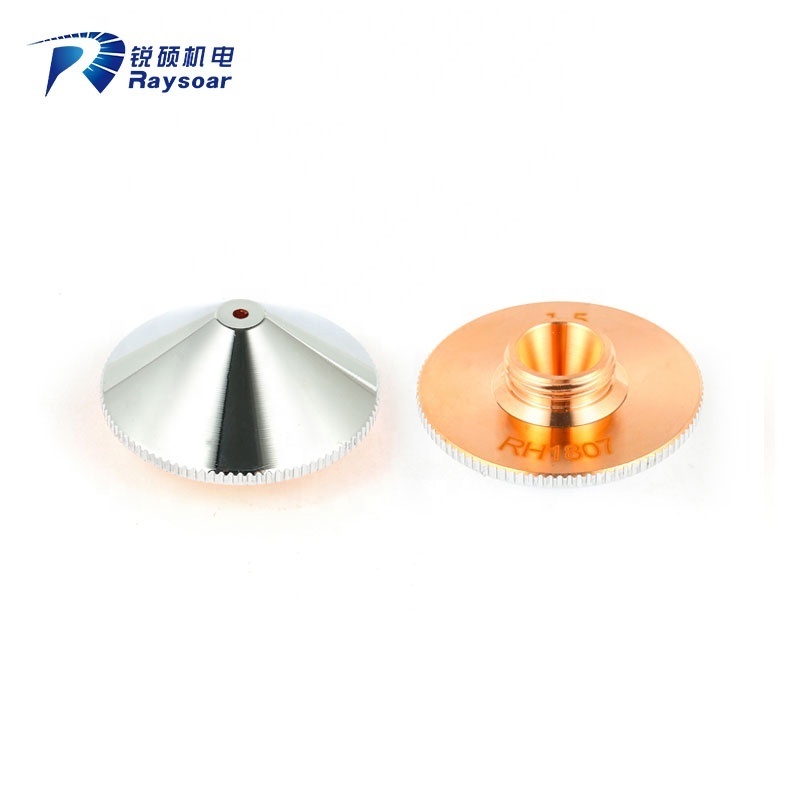

Copper/Chrome Plated

-

Used for:

-

Precitec,WSX cutting head

-

Diameter:

-

28mm

-

Height:

-

15mm

-

Thread:

-

M11

-

Caliber:

-

0.8-9.0mm

-

Service:

-

On line technical support

Quick Details

-

Place of Origin:

-

SHG

-

Spare Parts Type:

-

Consumables

-

Machinery Test Report:

-

Unavailable

-

Brand Name:

-

Raysoar

-

Weight (KG):

-

0.05 KG

-

Application:

-

Industrial laser cutting head

-

Keywords:

-

Laser cutting nozzle

-

Material:

-

Copper/Chrome Plated

-

Used for:

-

Precitec,WSX cutting head

-

Diameter:

-

28mm

-

Height:

-

15mm

-

Thread:

-

M11

-

Caliber:

-

0.8-9.0mm

-

Service:

-

On line technical support

|

Raysoar P/N

|

Description

|

OEM Ref.No.

|

OEM Brand

|

|||

|

LPTN01-5908

|

PT-Nozzle HD, 0.8 mm

|

P0591-673-00008

|

Precitec

|

|||

|

LPTN01-5910

|

PT-Nozzle HD, 1.0 mm

|

P0591-571-00010

|

Precitec

|

|||

|

LPTN01-5912

|

PT-Nozzle HD, 1.2 mm

|

P0591-572-00012

|

Precitec

|

|||

|

LPTN01-5913

|

PT-Nozzle HD, 1.3mm

|

|

Precitec

|

|||

|

LPTN01-5914

|

PT-Nozzle HD, 1.4 mm

|

|

Precitec

|

|||

|

LPTN01-5915

|

PT-Nozzle HD, 1.5 mm

|

P0591-573-00015

|

Precitec

|

|||

|

LPTN01-5916

|

PT-Nozzle HD, 1.6 mm

|

|

Precitec

|

|||

|

LPTN01-5917

|

PT-Nozzle HD, 1.7 mm

|

|

Precitec

|

|||

|

LPTN01-5918

|

PT-Nozzle HD, 1.8 mm

|

P0591-574-00018

|

Precitec

|

|||

|

LPTN01-5920

|

PT-Nozzle HD, 2.0 mm

|

P0591-575-00020

|

Precitec

|

|||

|

LPTN01-5923

|

PT-Nozzle HD, 2.3 mm

|

|

Precitec

|

|||

|

LPTN01-5925

|

PT-Nozzle HD, 2.5 mm

|

P0591-576-00025

|

Precitec

|

|||

|

LPTN01-5930

|

PT-Nozzle HD, 3.0 mm

|

P0591-577-00030

|

Precitec

|

|||

|

LPTN01-5935

|

PT-Nozzle HD, 3.5 mm

|

|

Precitec

|

|||

|

LPTN01-5940

|

PT-Nozzle HD, 4.0 mm

|

P0591-578-00040

|

Precitec

|

|||

|

LPTN01-5945

|

PT-Nozzle HD, 4.5 mm

|

|

Precitec

|

|||

|

LPTN01-5950

|

PT-Nozzle HD, 5.0 mm

|

P0591-579-00050

|

Precitec

|

|||

|

LPTN01-5960

|

PT-Nozzle HD, 6.0 mm

|

|

Precitec

|

|||

|

LPTN01-5970

|

PT-Nozzle HD, 7.0 mm

|

|

Precitec

|

|||

|

LPTN01-5980

|

PT-Nozzle HD, 8.0 mm

|

|

Precitec

|

|||

|

LPTN01-5990

|

PT-Nozzle HD, 9.0 mm

|

|

Precitec

|

|||

|

LPTN02-5908

|

PT-Nozzle double, 0.8 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5910

|

PT-Nozzle double, 1.0 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5912

|

PT-Nozzle double, 1.2 mm/inner 1.5 mm

|

P0591-002-00012

|

Precitec

|

|||

|

LPTN02-5914

|

PT-Nozzle double, 1.4 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-59125

|

PT-Nozzle double, 1.25 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5915

|

PT-Nozzle double, 1.5 mm/inner 1.5 mm

|

P0591-002-00015

|

Precitec

|

|||

|

LPTN02-5916

|

PT-Nozzle double, 1.6 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5918

|

PT-Nozzle double, 1.8 mm/inner 1.5 mm

|

P0591-002-00018

|

Precitec

|

|||

|

LPTN02-5920

|

PT-Nozzle double, 2.0 mm/inner 1.5 mm

|

P0591-002-00020

|

Precitec

|

|||

|

LPTN02-5923

|

PT-Nozzle double, 2.3 mm/inner 1.5 mm

|

P0591-002-00023

|

Precitec

|

|||

|

LPTN02-5925

|

PT-Nozzle double, 2.5 mm/inner 1.5 mm

|

P0591-002-00025

|

Precitec

|

|||

|

LPTN02-5930

|

PT-Nozzle double, 3.0 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5935

|

PT-Nozzle double, 3.5 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5940

|

PT-Nozzle double, 4.0 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5945

|

PT-Nozzle double, 4.5 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5950

|

PT-Nozzle double, 5.0 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5960

|

PT-Nozzle double, 6.0 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

LPTN02-5970

|

PT-Nozzle double, 7.0 mm/inner 1.5 mm

|

|

Precitec

|

|||

|

The chrome plated type is also available for all the above mentioned calibers.

|

|

|

|

|||

|

All original equipment manufacturer's names, drawings, colors, trademarks and part numbers are used for identification purposes only and we are in no way implying that any of our products are original equipment parts except for those original parts we indicated individually.

|

|

|

|

|||

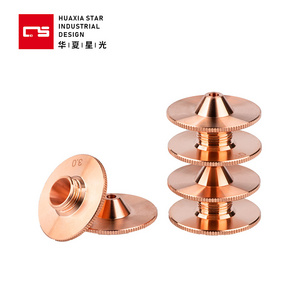

Double Layer Nozzle

The plug core is inserted into the standard cylindrical nozzle to improve the edge quality of the cutting sheet metal, split gas flow and prevent splashing.

It is mainly used for low pressure oxygen combustion supporting cutting of carbon steel. The double layer nozzle is also applied for high-power melting cutting.

Double Layer Chrome Plated Nozzle

Chrome plated nozzles enhance durability, and these nozzles are easier to clean,it can resist damage caused by "sheet or slag warping" and has better splash resistance than non-chrome plated nozzle. It suitable for all laser cutting applications.

Who are we?

●Raysoar is a trading company established in 2010 starting as a laser cutting machine consumables

distributor.

●We are not only a distributor. Raysoar focuses on one-stop service for industrial laser application

covering consumables & functional parts sell and technical solutions on laser cutting machine innovation

as well.

Consumables

Functional Components

Machine Solutions

Why choose us?

●We are professtional. We sell all consumables and functional parts applicable for most OEM brands including

Amada/Bystronic/Trumpf/Mitsubishi/NTC/Precitect/RayTools/WSX/Bodor etc.

●We sell the most cost-effective products. We focus on products quality and durability verification while

persisting in costs reducing therefore ensure the cost-effectiveness of each product.

●We provide technical service from the machine operation to the application and the maintenance as well

24 Hours On-line Service

On-line service by experienced technicians from the products installation to the machine operation response within 24 hours.

Q:

How to choose suitable model?

A: Please provide a photo of the product you used before or advise us your needs, we will give suggestions.

A: Please provide a photo of the product you used before or advise us your needs, we will give suggestions.

Q: What's your MOQ?

A:Normally one piece. If more, we can talk about discount. We can ship all parts you ordered together.

Q: Can I get discount?

A: The more you order, the more discount you will get.

A: The more you order, the more discount you will get.

Q: What is your terms of payment?

A: 100% in advance. Payment>=50000USD, 50% T/T in advance, balance before shipment.

A: 100% in advance. Payment>=50000USD, 50% T/T in advance, balance before shipment.

Q: How long is your delivery time?

A: When the order is confirmed, 3-5 working days for the small order, 2-6 weeks for the bulk depending on the quantity and product type.

A: When the order is confirmed, 3-5 working days for the small order, 2-6 weeks for the bulk depending on the quantity and product type.

Q: Can I get a sample to check the quality ?

A: Yes, we are glad to offer you sample for test, and there is a discount for Trade Assurance Sample Order.

A: Yes, we are glad to offer you sample for test, and there is a discount for Trade Assurance Sample Order.

Q: Why choose us?

1. We have full ranges of spare parts for various brands of laser cutting and welding machine.

2. We have professional procedure system and big production capacity to guarantee fast delivery and on time shipment.

3. We can provide the most competitive price to meet your budget.

4. We also design and innovate the new products based on our rich experience .

5. We have professional team to provide comprehensive one-stop service for you.

1. We have full ranges of spare parts for various brands of laser cutting and welding machine.

2. We have professional procedure system and big production capacity to guarantee fast delivery and on time shipment.

3. We can provide the most competitive price to meet your budget.

4. We also design and innovate the new products based on our rich experience .

5. We have professional team to provide comprehensive one-stop service for you.

Hot Searches