- Product Details

- {{item.text}}

Quick Details

-

Coil Weight (T):

-

12

-

Leveling Precision(±mm/m):

-

0.5 ±mm/m

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Darling Machinery

-

Voltage:

-

380V/220V/415V/440V/customized

-

Rated Power:

-

110KW

-

Dimension(L*W*H):

-

30mLX8mW

-

Weight:

-

35

-

Product name:

-

automatic uncoiling leveling cutting machine

-

Application:

-

cold steel coil

-

Function:

-

uncoiling leveling cutting stacking

-

Steel coil thickness:

-

0.5-5 mm automatic uncoiling leveling cutting machine

-

Steel coil width:

-

600-1250mm automatic uncoiling leveling cutting machine

-

Production speed:

-

25m/min automatic uncoiling leveling cutting machine

-

Leveling precision:

-

1mm/m2 automatic uncoiling leveling cutting machine

-

Continuous shearing times:

-

30times/min automatic uncoiling leveling cutting machine

-

Stacking device:

-

have automatic uncoiling leveling cutting machine

-

Certification:

-

CE ISO9001 automatic uncoiling leveling cutting machine

Quick Details

-

Cutting Width (mm):

-

500 - 3000 mm

-

Material Thickness(mm):

-

0.5 - 3 mm

-

Cutting Speed(m/min):

-

20 - 60 m/min

-

Coil Weight (T):

-

12

-

Leveling Precision(±mm/m):

-

0.5 ±mm/m

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Darling Machinery

-

Voltage:

-

380V/220V/415V/440V/customized

-

Rated Power:

-

110KW

-

Dimension(L*W*H):

-

30mLX8mW

-

Weight:

-

35

-

Product name:

-

automatic uncoiling leveling cutting machine

-

Application:

-

cold steel coil

-

Function:

-

uncoiling leveling cutting stacking

-

Steel coil thickness:

-

0.5-5 mm automatic uncoiling leveling cutting machine

-

Steel coil width:

-

600-1250mm automatic uncoiling leveling cutting machine

-

Production speed:

-

25m/min automatic uncoiling leveling cutting machine

-

Leveling precision:

-

1mm/m2 automatic uncoiling leveling cutting machine

-

Continuous shearing times:

-

30times/min automatic uncoiling leveling cutting machine

-

Stacking device:

-

have automatic uncoiling leveling cutting machine

-

Certification:

-

CE ISO9001 automatic uncoiling leveling cutting machine

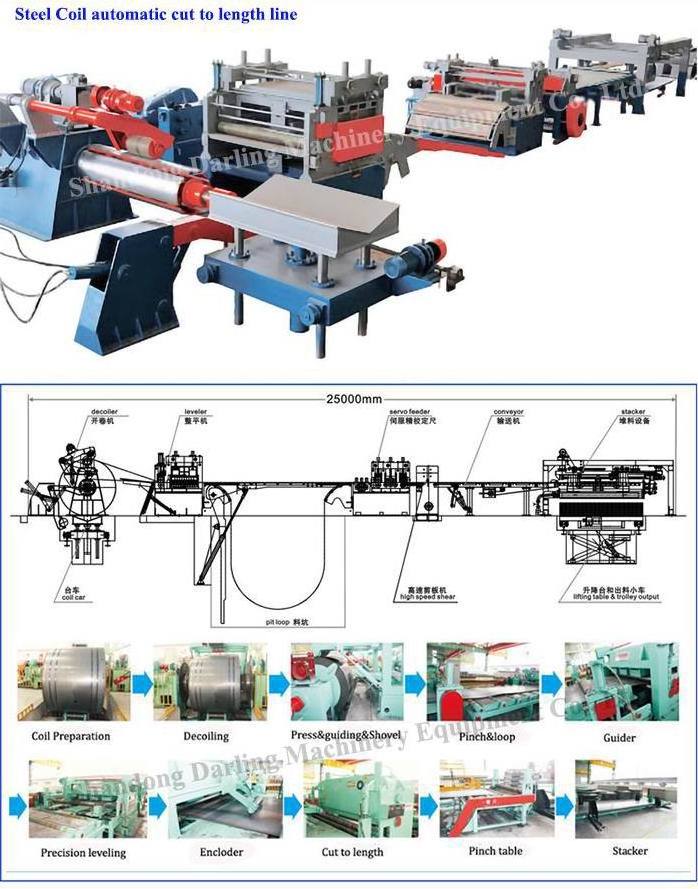

Chinese professional HTT44-5x1250 steel coil automatic uncoiling leveling cutting machine

Video link:

YouTube: https://youtu.be/zGFaHtitYco

QQ video: https://v.qq.com/x/page/b32158vf8mi.html

Baidu video: https://haokan.baidu.com/v?vid=4605804851956389733&bfe=1

Production line main parameters

|

No. |

Name |

Specification and parameters |

|

1 |

Steel coil thickness |

0.5-3.0mm |

|

2 |

Steel coil width |

800--2000mm |

|

3 |

Cutting accuracy |

Length:±0.5mm based on 2000mm length Long gauge diagonal ±1mm based on 2000mm length |

|

4 |

Cutting length |

500-3000mm |

|

5 |

Production line working height |

About 1150mm |

|

6 |

Production line speed |

20-60m/min Speed segment adjustable |

Production line equipment composition

|

No. |

Name |

|

1 |

Loading trolley |

|

2 |

Single cantilever uncoiling machine |

|

3 |

Material guiding and leveling machine |

|

4 |

Hydraulic bridge + correction device |

|

5 |

Servo size confirming machine |

|

6 |

High-speed pneumatic cutting machine |

|

7 |

Material feeding platform |

|

8 |

Material stacking machine + lifting machine + unloading trolley |

|

9 |

Hydraulic and pneumatic systems |

|

10 |

Electric control and automation |

15-axis fine leveling machine

The leveling machine adopts the gear box universal joint transmission, additional support rollers are up and down, the sheet is sent to the middle of the leveling roller, and the leveling purpose is achieved after repeated deformation in the forward and reverse directions. It is mainly composed of frame part, working roller part, lifting part and main transmission part. The frame adopts a steel plate welded box structure. The working roller part, the lifting part and the frame part are organically combined. The shape is novel, the structure is reasonable, and the installation and maintenance are convenient. The working roller is a front-to-back roll, which is driven by a universal joint of the gear box. Active up and down. Reach the corresponding leveling of different material steel plates. The function of the lifting part is to lift the up working rollers, adjusting the working space, the purpose of lifting the up rollers is achieved by using a motor-driven reducer to drive screw rod.

Main technical parameters

(1) Leveling plate thickness: 0.5-3.0mm

(2) Leveling plate width: 2000mm

(3) Leveling roller diameter: φ 130mm 40Cr medium frequency quenching 50°-55° surface is plated with hard soldering.

(4) Leveling roller length: 2200mm

(5) Main motor power: 37KW motor (Chinese famous brand)

(6) Speed reducer: 200 worm gear reducer

(7) Oil lubrication system: Centralized oil supply

cutting machine (Pneumatic high-speed cutting machine, air source supplied by user)

It is mainly composed of left and right brackets, connecting rods, up and down knife rack , worktable , driving part, etc . it also can be prepared by the user, or selected according to user requirements.

The main technical parameters:

(1) Max . cutting thickness: 4.0mm

(2) Cut ting width: 2200mm

(3) Motor power: about 15KW (Chinese famous brand)

(4) Blade material: 6CrW2Si

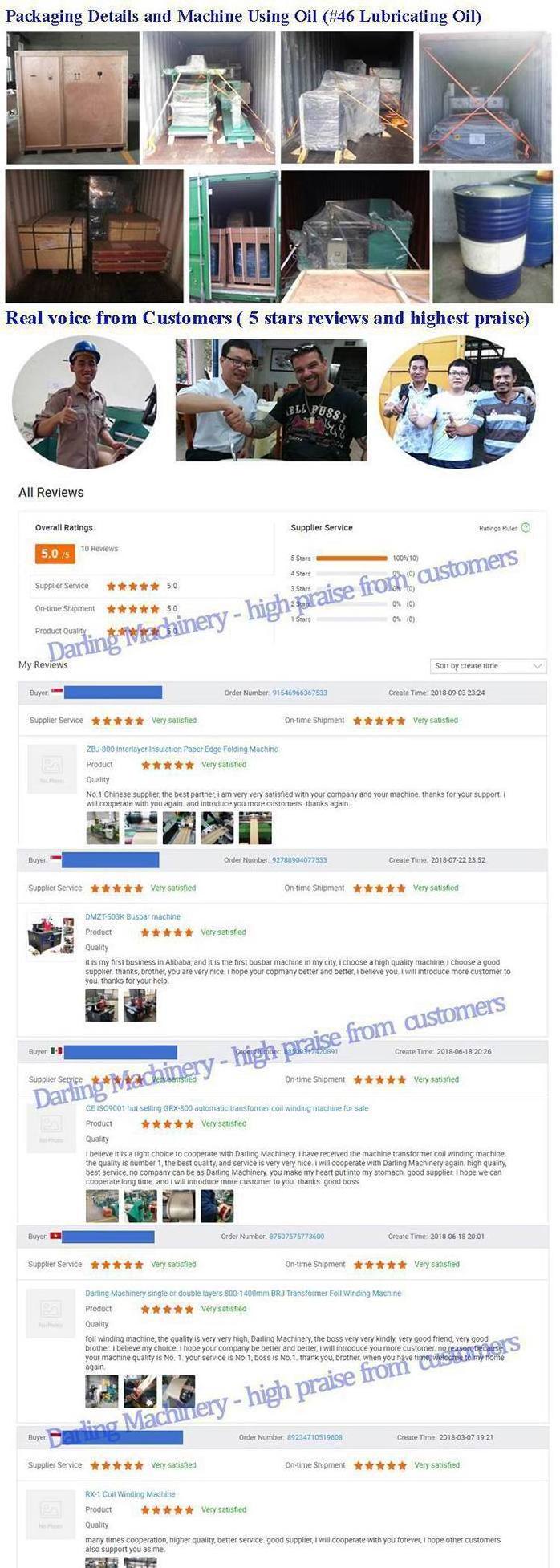

Our service

1, before sales: we will give you professional instruction and help you to buy the suitable machine, after you choose our machine, let you take the biggest profit through using our machine.

2, in sales: we will give you feedback informations about your order through photos and video. let you put your heart into stomach.

3, after sales: we will go to your factory to give you a training and teach you how to use our machine, or we will give you a video training. if there is our local agent and office, we will let our local engineer to your factory and give you a training.

4, our quality assurance: all our machine using life.

Getting Local office support, please contact with our company:

|

Shandong Darling Machinery Equipment Co., Ltd.

Add: Shacun Industry Park, Licheng District, Jinan City, China. Contact person: Martin Hoo +86-15253156158 (WhatsApp) Skype/Wechat: martinhoo936 QQ: 613252158 Website: www.darlingmachinery.com |

We will be the best partner

Although we live in different countries, our hearts are always together . We don ’ t only sell machine, we also sell service, technology and brand. One time cooperation, be friend forever!

Our cooperation is Double win results.

® Our aim is:

Through using our machine, you can make better product and earn more money !

FAQ:

1, are you manufacture or trading company?

we are manufacture more than 15 years, 3 branch factory, more than 10000 square meters.

2, how about your quality ?

we only sell high quality machine, we use the world famous brand component, like SIEMENS, MITSUBISHI, DELEM, PANASONIC, SCHNEIDER, ABB, etc. so there is no worry about our quality.

3, what about your after sales service ?

we go to your factory for site training or you can get local branch company traning, if there is no requirement, we can give you video training in other methods.

4, why do we must choose you as our supplier ?

customer real voice is your best reference, 5 stars customer feedback reviews, 100% high praise. those voice can let you to cooperate with us safely.