glaze, printing, etc., when the surface of the fired parts is not cleaned (inorganic, organic and other dirt attachments), the operation time is long, resulting in uneven layer thickness, uneven seed layer thickness, uneven drying and incomplete drying, air bubbles in the shaft layer, and uneven surface of the hidden crack of the glaze layer, it is easy to have surface subsidence after firing.

- Product Details

- {{item.text}}

Quick Details

-

Processing Service:

-

milling, formula

-

Product name:

-

low temperature powdered frits gor glass ceramic

-

Keywords:

-

low temperature powdered frits

-

MOQ:

-

1000kgs

-

Color:

-

various

-

Size:

-

Size Customized

-

Certificate:

-

ISO9001

-

Service:

-

24 Hours Online

-

Packaging:

-

Wooden Crate

-

Usage:

-

glass ceramic glazing frit

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

99#

-

Brand Name:

-

TRASTAR

-

Processing Service:

-

milling, formula

-

Product name:

-

low temperature powdered frits gor glass ceramic

-

Keywords:

-

low temperature powdered frits

-

MOQ:

-

1000kgs

-

Color:

-

various

-

Size:

-

Size Customized

-

Certificate:

-

ISO9001

-

Service:

-

24 Hours Online

-

Packaging:

-

Wooden Crate

-

Usage:

-

glass ceramic glazing frit

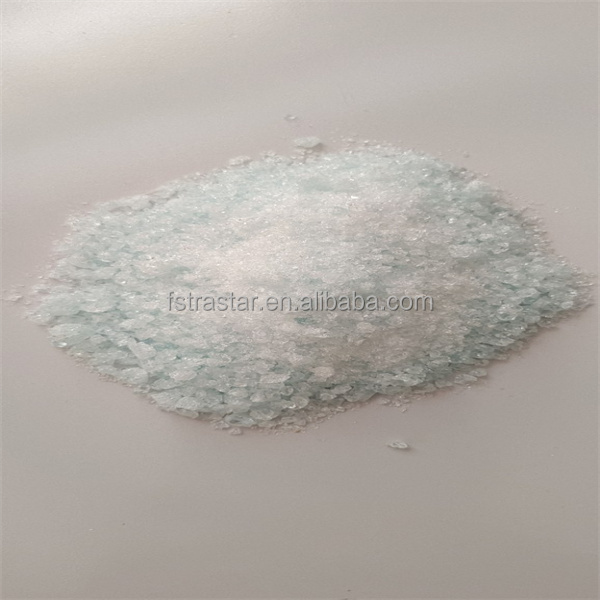

Products Description

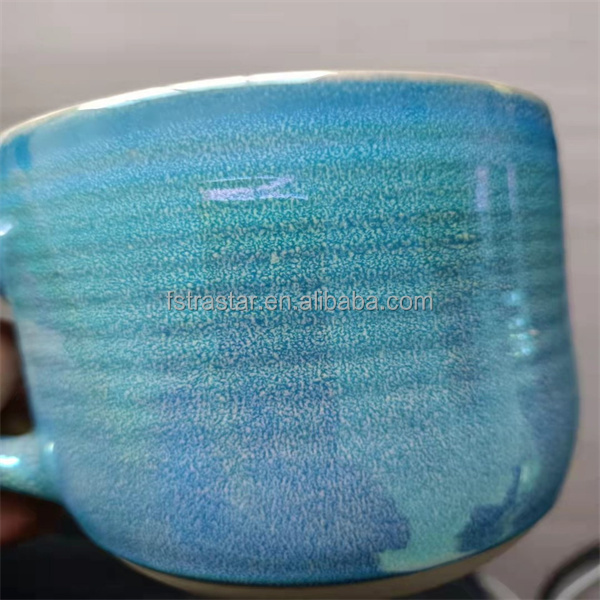

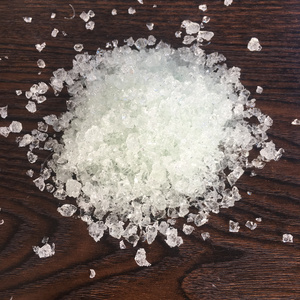

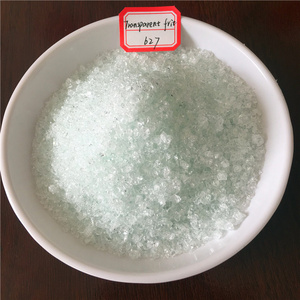

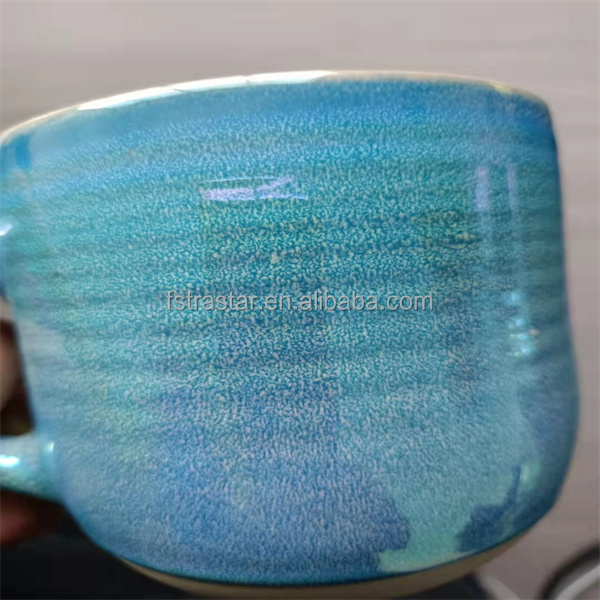

Reactive glaze frit, kiln change glaze frit, lead-free metal glaze glass frit, high boron glass frit, transparent glass frit, zirconium white glass frit

Low Temperature frit/fluxfor glass ceramic,metal and coating production and

Process and technical precautions should select materials with the temperature corresponding to its process, preparation and other materials.

The effect of sleeve materials after use is relatively affected by other factors such as the proposed process and use,and its material mix. Therefore, different customers have different differences. The glaze content and liquid content ratio of the meal slurry will affect the color concentration The furnace temperature difference (such as furnace type and size, furnace position, temperature measuring point position, characteristics of fired parts, size and thickness, etc.), such as service performance, will affect the effect of the material after use, resulting in fluctuations. Because of the furnace temperature difference, the measurement cannot reach the actual material use temperature. After the material is fired, there will be no light and powder, uneven or insufficient gloss, etc. If the measurement degree exceeds the actual required use degree of glaze, the effect of glaze will change after use. After the slurry undergoes glaze application processes such as dipping, coating, spraying

Low temperature glass,ceramic frit/flux's application techonoligy and application materials

Low temperature

Frit/flux glaze for screen printing,spraying,painting and curtaining production method.

Low temperature Frit/flux glaze used iin ceramic,glass,metal,electronics and coating materials.

Our Advantages

Stable frit

During the frit production process, our company has its own kiln and produces it all year round.

Stable frit prodcution

The entire production process has strict management regulations. Frit stability is the core requirement of our production!

Details Images

Product packaging

Contact US freely

Our Contact information,please contact freely. Wish to build good and long business with YOU.

Marketing Manager: Jessica chang/Miles

Mob:+86-18566432990 Tel /fax:0757-82263565

Wechat: fsjc_757

Whats APP:+86-13074254327

Address: No.50,3 floor, Hedang, Wanggang RD , Foshan, China.

Hot Searches