- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Honesun

-

Model Number:

-

HS-ND001

-

Product Name:

-

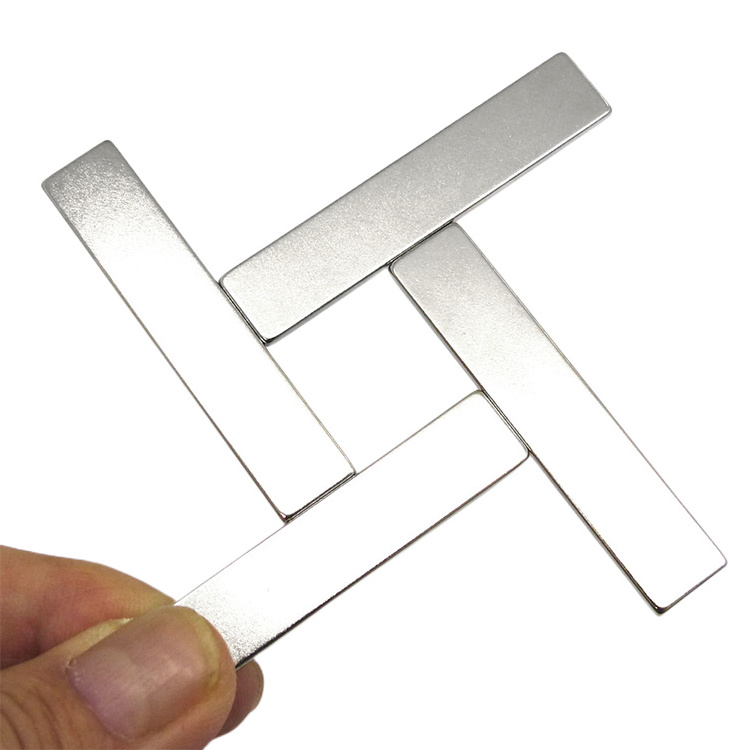

High performance N52 rectangle neodymium magnet for sale

-

Grade BH:

-

N35,N38,N40,N42,N45,N48,N50,N52

-

Plating:

-

Nical,Zinc,Gold,Silver,Epoxy,Passivated,etc.

-

Max Working Temperature:

-

200Degree C

-

Quality System:

-

ISO9001:2001

-

Environment:

-

RoHS

Quick Details

-

Tolerance:

-

±0.02mm

-

Grade:

-

NdFeB, N,M,H,SH,UH,EH series

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Honesun

-

Model Number:

-

HS-ND001

-

Product Name:

-

High performance N52 rectangle neodymium magnet for sale

-

Grade BH:

-

N35,N38,N40,N42,N45,N48,N50,N52

-

Plating:

-

Nical,Zinc,Gold,Silver,Epoxy,Passivated,etc.

-

Max Working Temperature:

-

200Degree C

-

Quality System:

-

ISO9001:2001

-

Environment:

-

RoHS

Product Description

2) Processing according to design drawings

3) Requirements for Magnetization Direction

4) Magnet Grade requirements

5) Surface Treatment requirements (coating requirements) 6) Packaging requirements

More Options

You May Also Like

Coating / Plating

Which coating is the best for your magnet?

NiCuNi coating : The nickel coating is composed of three layers, nickel-copper-nickel. This type of coating

is the most widely used and provides protection against corrosion of the magnet in outdoor situations.

Processing costs are low. The maximum working temperature is approximately 220-240ºC (depending on

the maximum working temperature of the magnet). This type of coating is used in engines, generators,

medical devices, sensors, automotive applications, retention, thin film deposition processes and pumps.

Black nickel : The properties of this coating are similar to those of the nickel coating, with the difference

that an additional process is generated, the black nickel assembly.

Zinc : If the maximum working temperature is less than 120°C, this type of coating is adequate. The costs

are lower and the magnet is protected against corrosion in the open air. It can be glued to steel, although

a specially developed adhesive must be used. The zinc coating is suitable provided that the protective

barriers for the magnet are low and low working temperatures prevail.

Epoxy : A coating that provides an excellent barrier against salt and water. There is a very good adhesion

to steel, if the magnet is glued with a special adhesive suitable for magnets. The maximum working

temperature is approximately 150 ° C. Applications can be found in the maritime sector, engines, sensors,

consumer goods and the automotive sector.

Magnetic direction

Neodymium magnet applications

Quality Control

Demagnetization Curve

What is a demagnetization curve?

Demagnetization curve provides information about the magnetic characteristics of a magnet,It provides

information about the strength of the magnet, how hard it is to demagnetize, and how a magnet's shape

(or use in a magnetic circuit) affects matters. When a permanent magnet is fully magnetized, its magnetic

domains are aligned. Certain conditions such as temperature and reverse magnetic fields can cause

some of the domains to lose this alignment and reverse, triggering the magnet to lose some or all of its

magnetic field.

Feedback