- Product Details

- {{item.text}}

Quick Details

-

Machinery Capacity:

-

100-1000kg/h

-

Machinery Function:

-

Multifunctional

-

Brand:

-

DECAO

-

After Warranty Service:

-

1 Year

-

Material:

-

304 Stainless Steel

-

Type:

-

Automatic

-

Function:

-

Effficient

-

Voltage:

-

380V/50Hz

Quick Details

-

Weight (KG):

-

1500

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Delon/Decao

-

Machinery Capacity:

-

100-1000kg/h

-

Machinery Function:

-

Multifunctional

-

Brand:

-

DECAO

-

After Warranty Service:

-

1 Year

-

Material:

-

304 Stainless Steel

-

Type:

-

Automatic

-

Function:

-

Effficient

-

Voltage:

-

380V/50Hz

Products Description

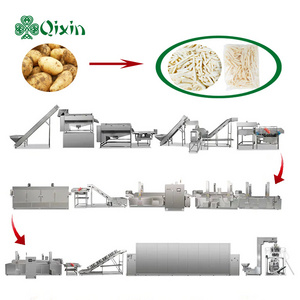

Industrial 300-1000kg/hour fully automatic potato frozen french fries production line / Potato chips making machine

Full automatic composite potato chip production line - it is the whole process of automatic production from raw material mixing and stirring, pressing dough, printing and molding, frying and molding, seasoning, cooling and transportation, and completes the whole production process from powdered raw materials to finished potato chips. The production lines are made of stainless steel, with stable operation and high degree of automation. They have won 11 technical patents, and have a fully automatic crushing and recycling mechanism and frying and filtering mechanism to effectively realize the functions of waste material collection and reuse and oil residue filtration.

Main features:

Potato Chips French Fries Production Line

1.PLC control, intuitive display, simple operation.

2.Most of the equipment is made of food grade 304 stainless steel.

3.The new recycling structure can recycle and reuse the leftover materials, with high efficiency of raw materials.

4.The integrated molding mold can obtain potato chips with uniform shape, which is convenient for sorting and barrel packing.

5.The new filtering structure can effectively filter oil residue.

6.Vertical bag packaging, bag feeder packaging or paper barrel packaging can be selected.

Apart from using potato as material, you could also use other food as well, such as sweet potato, carrot and other kinds of taros.

1.PLC control, intuitive display, simple operation.

2.Most of the equipment is made of food grade 304 stainless steel.

3.The new recycling structure can recycle and reuse the leftover materials, with high efficiency of raw materials.

4.The integrated molding mold can obtain potato chips with uniform shape, which is convenient for sorting and barrel packing.

5.The new filtering structure can effectively filter oil residue.

6.Vertical bag packaging, bag feeder packaging or paper barrel packaging can be selected.

Raw materials:

Potato Chips French Fries Production Line

Machines materials:

Potato Chips French Fries Production Line

All the machines are made by stainless steel.

Parameters:

Potato Chips French Fries Production Line

|

Model

|

DL-3000-A

|

|

Input Voltage

|

380V/50Hz

|

|

Installed Power

|

376KW

|

|

Power Consumption

|

280KW

|

|

Production Capacity

|

150-200kg/h

|

|

Length

|

43000mm

|

Sample:

Potato Chips French Fries Production Line

Flow chart:

Potato Chips French Fries Production Line

Washing → Peeling → Cutter → Washing → Blanching → Drying → Frying → Freezing → Weighing → Packing

Packing and Delivery

1.Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

2.Customer's requirement is available.

3.If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country); by ship-please tell me your delivery port.

Our Service

--Before sale:

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

--During

sale:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout

2.Welcome to visit our factory or the domestic clients' factory.

3.Inspect the machine before leaving the factory.

--After sale:

1.Oversea install and debug the equipment.

2.Train the first-line operator.

3.Provide the basic formula.

4.Operation/ Service/ Maintenance Manual: Provided In English.

5.1-2 engineers will be arranged for customer

Our Company

Jinan Delon Machinery & Equipment Co., Ltd. is a high and new technology enterprise integrating technology, manufacture and trade.We have devoted ourselves to developing, manufacturing and trading double/single screw extruders, snack production lines, breakfast cereal/corn flake production lines, soya meat production lines, pasta/macaroni production lines, pet food production lines, etc. for more than 10 years.

FAQ

Q:Are you manufacturer?

A: Yes, we are manufacturer, welcome to visit our factory and check the machines.

Q: Can you design new mold for us if we have good idea?

A: Yes,we can design new mold for you according to your original market needs.

Q:Can you help us to design the whole line if we provide the layout of our factory?

A:Yes,we can provide you machine layout at your factory after get your factory details.

Q: What information should I provide, if I want a quotation?

A:---The kind of machine you choose, or offer me the kinds of food you will produce.

--- Your production capacity requirement.

---Provide us your production details, then we give professional suggestion to you.

Q: Why choose us?

A: --- Professional technology, we have been engaged in manufacturing food processing machine for many years, accumul ating rich

experience and enjoying high reputation.

---Fast delivery and good service.

A: Yes, we are manufacturer, welcome to visit our factory and check the machines.

Q: Can you design new mold for us if we have good idea?

A: Yes,we can design new mold for you according to your original market needs.

Q:Can you help us to design the whole line if we provide the layout of our factory?

A:Yes,we can provide you machine layout at your factory after get your factory details.

Q: What information should I provide, if I want a quotation?

A:---The kind of machine you choose, or offer me the kinds of food you will produce.

--- Your production capacity requirement.

---Provide us your production details, then we give professional suggestion to you.

Q: Why choose us?

A: --- Professional technology, we have been engaged in manufacturing food processing machine for many years, accumul ating rich

experience and enjoying high reputation.

---Fast delivery and good service.

---All the machines are strictly inspected before making shipment.

---Alibaba assessed supplier.

---Provide basic formula.

---Alibaba assessed supplier.

---Provide basic formula.

Hot Searches