- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HengDa

Ceramic Tumbling Media, Vibratory Polishing Deburring Media

Ceramic Tumbling Media, Vibratory Polishing Deburring Media

Ceramic tumbling media for mass finishing is formulated for general purpose polishing, light and heavy deburring, fast and extra fast deburring, Ceramic media is best choice for harder metals such as steel and stainless steel and it is also used on softer metals such as aluminum, brass.

Ceramic Tumbling Finishing Media Benefits

1. Ceramic tumbling media is highly durable and long lasting, which reduce operating cost,

2. Offering fast and aggresive cutting action results in shorter cycle time.

3. Suitable for light or heavy tumbling, polishing, deburring, edge rounding.

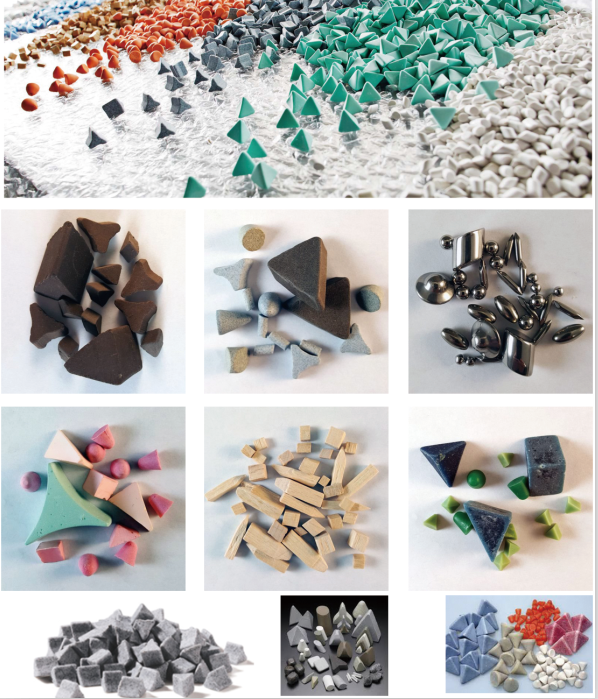

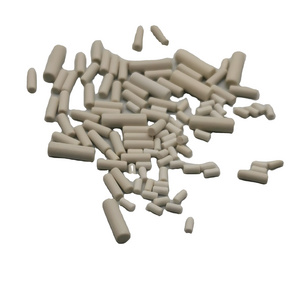

4. Wide variety of shapes and sizes, such as Balls, Cones, Pyramids, Cylinders, Triangles, Tristars, etc

How to choose mass finishing medias?

Finishing media comes in a range of sizes and shapes, from cylinders and balls to triangles, pyramids and sharp-edged stars. Choosing the shape of the finishing media.is often determined on the shape of the parts being finished.

For general use, ball or cylindrical media is preferred, as rounded surfaces is more wear-resistent with much lower chipping rates, even better, they have less chance of lodging in parts than sharp wedges. Triangles, pyramids and tri-star shapes are better suited for touching complex parts with hard-to-reach corners, but they come with higher wear rate and are more likely to chipping.

For size, smaller medias get more contacts on surfaces and finish in low speed, which create finer effect, while larger media provides rapid removal of burs and shape egdes.

Mass finishing tumbling media - we can guarantee the right shape, size, and composition to rightly fit your vibratory finishing requirements. Just contact with us for your solution!