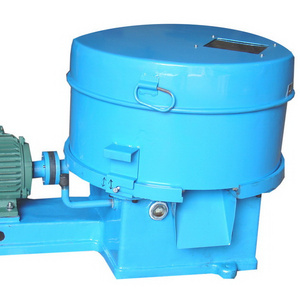

Type Single sleeve Capacity ~ 20 t/h

Alpha set process Height of opening for loading sand ~ 2. 0 50 mm

Sand discharge hole height ~ 1.000 mm

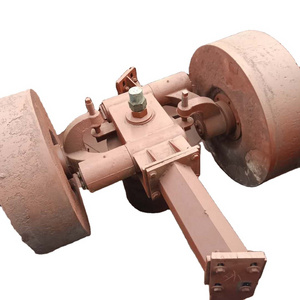

Sleeve Type :Auger

Auger drive power :~ 15 kW Resin

pump power 0.75KW

pump power 0.75KW

Slow hardener pump power 0.55 kW

Fast hardener pump power :0.55 kW

Manufacturer :China