- Product Details

- {{item.text}}

Quick Details

-

Power:

-

75KW

-

Dimension(L*W*H):

-

2300X1300X1800MM

-

Weight (KG):

-

1000

-

Product name:

-

Wood Shredder Crusher Machine

-

Final product:

-

1-10mm Sawdust

-

Capacity:

-

1-3t/h

-

Type:

-

Blade Cruhser

-

Suitable for:

-

Wood Crusher

-

Suitable material:

-

Tree Wood Branch Corn Cob

-

Engine:

-

Diesel Engine Motor

-

Packing:

-

Wooden Case

-

Speed:

-

2600 r/min

-

Maximum diameter of wood branches:

-

250mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

yugong

-

Voltage:

-

380V

-

Power:

-

75KW

-

Dimension(L*W*H):

-

2300X1300X1800MM

-

Weight (KG):

-

1000

-

Product name:

-

Wood Shredder Crusher Machine

-

Final product:

-

1-10mm Sawdust

-

Capacity:

-

1-3t/h

-

Type:

-

Blade Cruhser

-

Suitable for:

-

Wood Crusher

-

Suitable material:

-

Tree Wood Branch Corn Cob

-

Engine:

-

Diesel Engine Motor

-

Packing:

-

Wooden Case

-

Speed:

-

2600 r/min

-

Maximum diameter of wood branches:

-

250mm

Industrial Wood Chipper Machines Wood Chipper Machine

Product Description

|

Model

|

YG-6130

|

YG-6145

|

|

Production Capacity

|

2 tons/hour

|

5 tons/hour

|

|

Power

|

23.6 KW

|

75 KW(102 HP)

|

|

Maximum diameter of wood branches

|

130 mm

|

250 mm

|

|

Cutter roller disc diameter

|

300 mm

|

500 mm

|

|

Speed

|

2600 r/min

|

2500 r/min

|

|

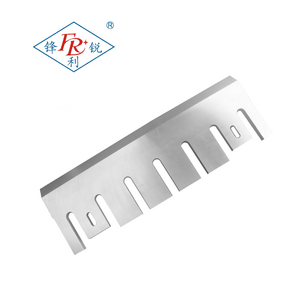

Number of blades

|

4 moving blades, 1 stationary blade

|

4 moving blades, 1 stationary blade

|

|

Blade length

|

155 mm

|

230 mm

|

|

Feed roller diameter

|

280 mm

|

500 mm

|

|

Overall dimension

|

2300×1300×1800 mm

|

3200×1700×2400 mm

|

|

Packing Size

|

2400×1400×1100 mm

|

3350×1850×1550 mm

|

|

Total Weight

|

980 kg

|

2600 kg

|

The newly developed and produced garden wood branch shredder is suitable for gardens, orchards, forestry, highway tree maintenance, parks, golf courses and other departments.

The equipment is simple to operate, one-time molding, after crushing, it can be used as mulch, garden bed base, organic fertilizer, edible fungus, biomass power generation, and can also be used for the production of high density board, particle board, paper industry, etc.

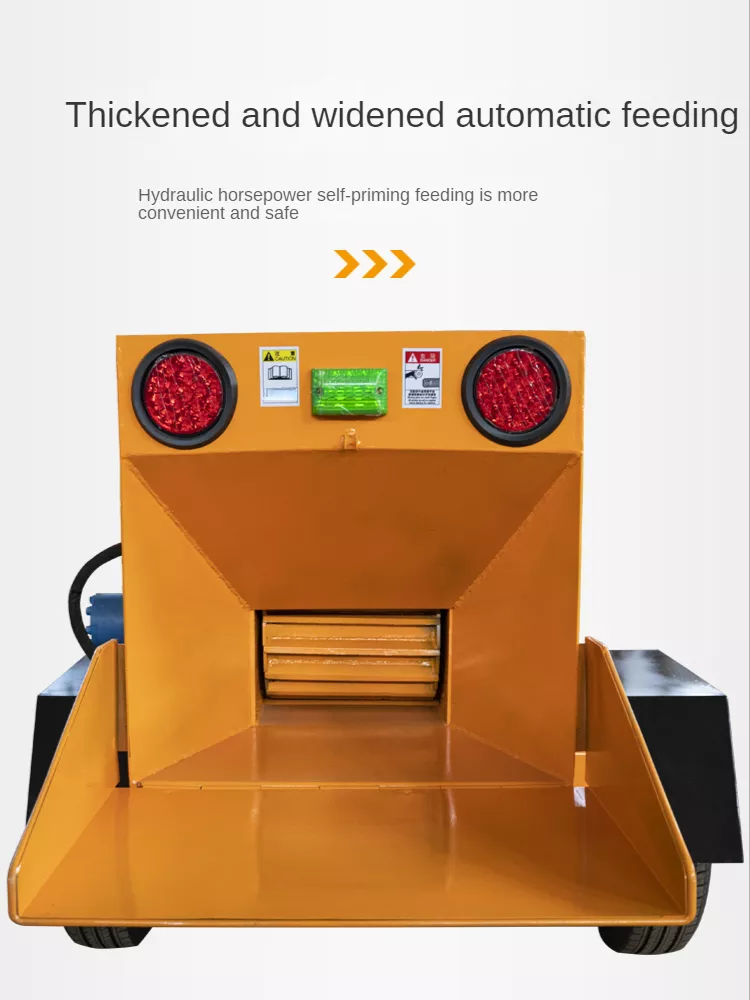

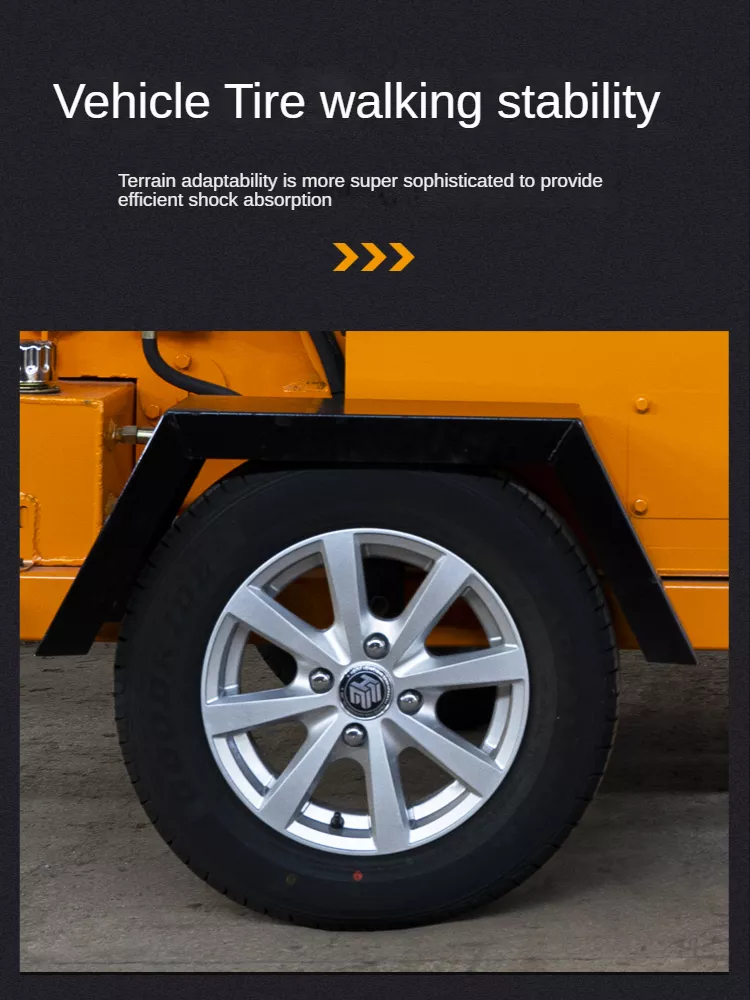

After crushing, it can be directly sprayed into the transportation vehicle, and the volume can be reduced by 80%-90% after crushing, which not only reduces the transportation cost, but also saves manpower, material resources, energy saving and emission reduction. The garden-specific branch crusher produced by our company can be driven by a diesel engine, and is equipped with tires, platforms, and traction devices. It is flexible and can crush branches anytime and anywhere. It is very convenient for field operations or roadside work.

The equipment is simple to operate, one-time molding, after crushing, it can be used as mulch, garden bed base, organic fertilizer, edible fungus, biomass power generation, and can also be used for the production of high density board, particle board, paper industry, etc.

After crushing, it can be directly sprayed into the transportation vehicle, and the volume can be reduced by 80%-90% after crushing, which not only reduces the transportation cost, but also saves manpower, material resources, energy saving and emission reduction. The garden-specific branch crusher produced by our company can be driven by a diesel engine, and is equipped with tires, platforms, and traction devices. It is flexible and can crush branches anytime and anywhere. It is very convenient for field operations or roadside work.

Features

The hydraulic forced feeding system is conducive to reducing the volume of fluffy branches and feeding quickly. The front pressing roller can prevent the material from flowing back and ensure the safety of use. The drum cutter rotor structure optimizes the cutting effect and can easily crush 20 cm logs to obtain higher output. The finished product is more suitable for making organic fertilizer and ground cover.

1.Automatic feeding:Easy to operate and high production efficiency.

2.Stable working:continuous roll crushing with dynamic balance treatment.

3.Durable:Steel parts are made of high quality material, long life high power self-aligning bearing.

4.Low cost: low power consumption high-end tool, double-sided edge.

5.Easy to move: It can be designed as a mobile crusher for on-site production.

2.Stable working:continuous roll crushing with dynamic balance treatment.

3.Durable:Steel parts are made of high quality material, long life high power self-aligning bearing.

4.Low cost: low power consumption high-end tool, double-sided edge.

5.Easy to move: It can be designed as a mobile crusher for on-site production.

Packing & Delivery

Hot Searches