- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Fujian, China

-

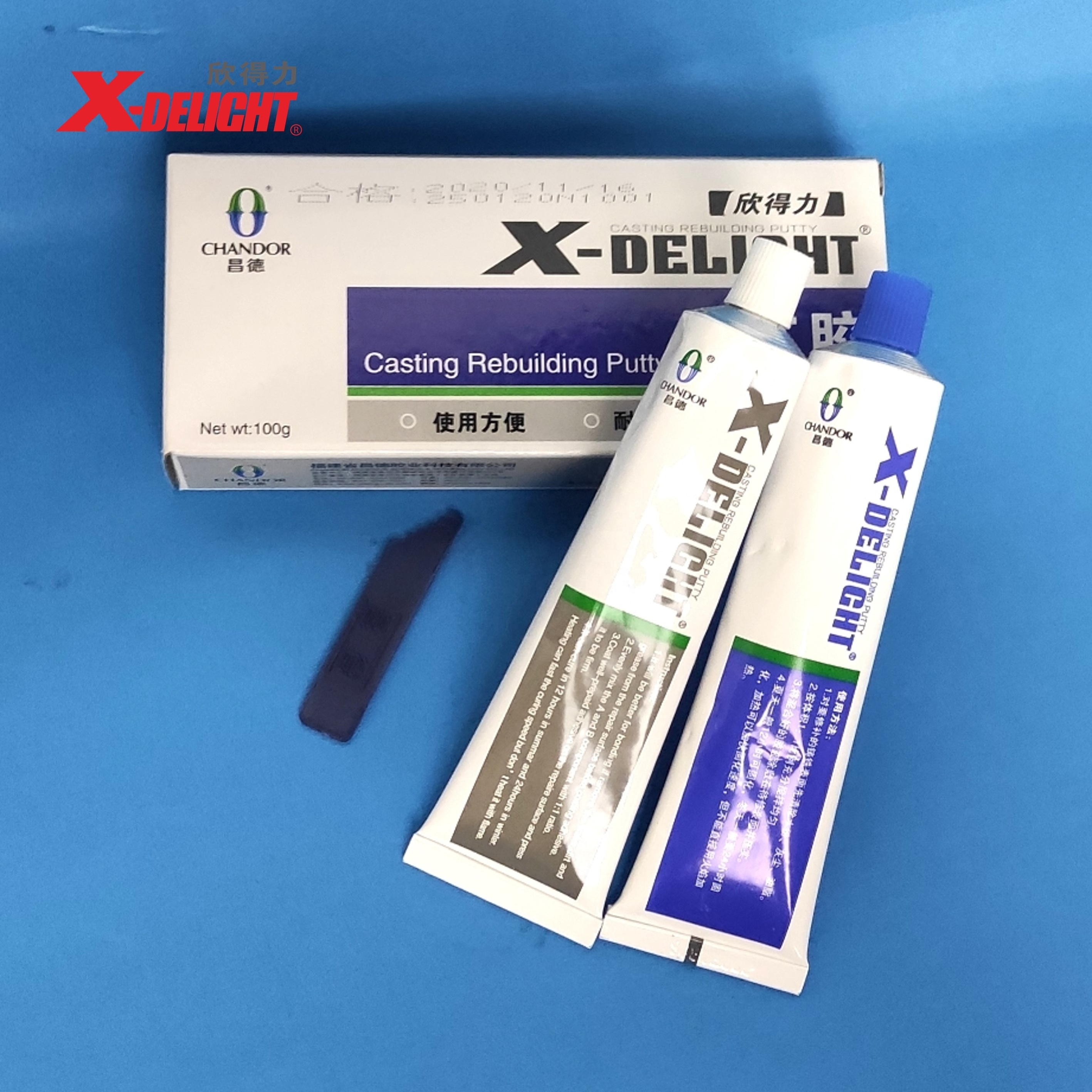

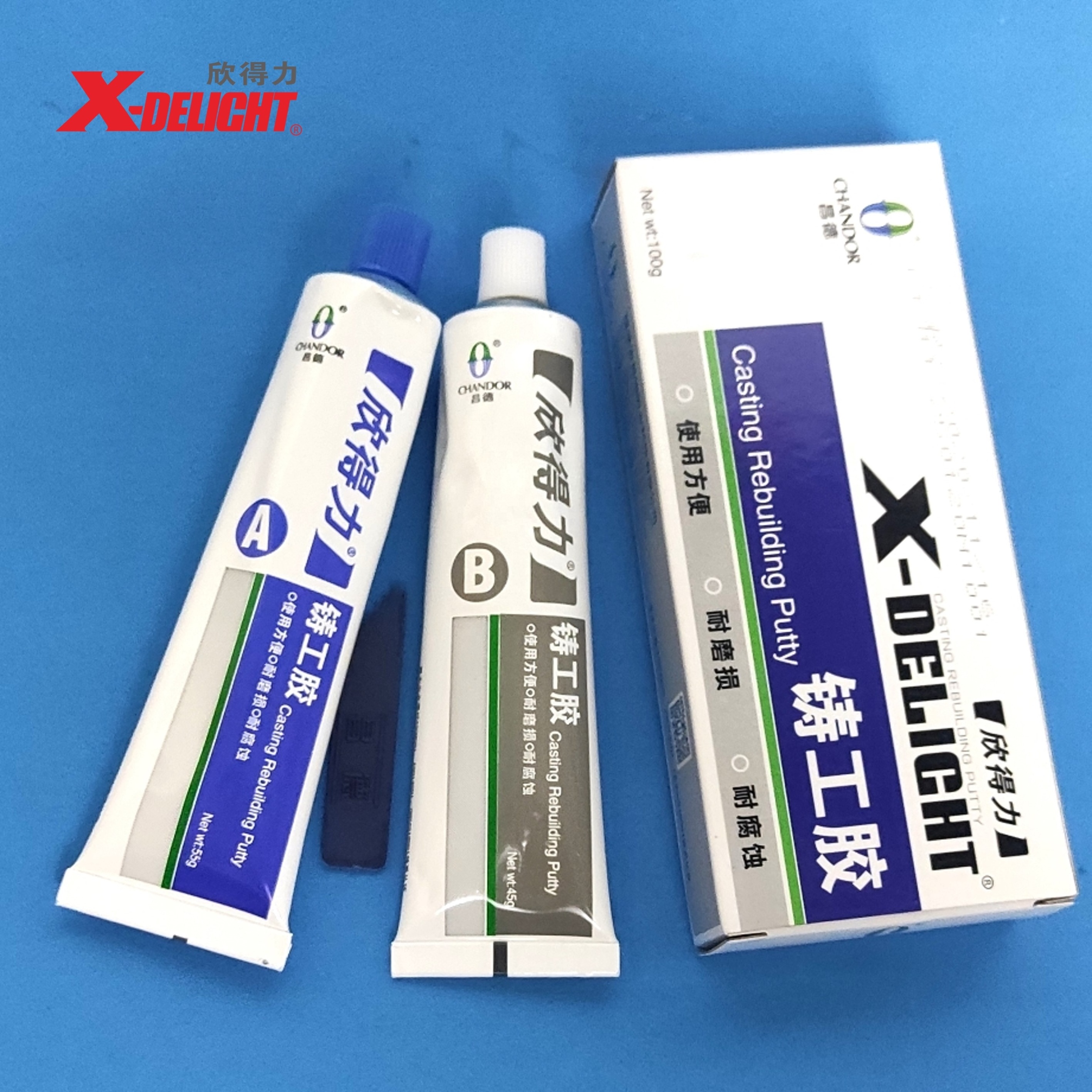

Brand Name:

-

X- DELIGHT

-

Model Number:

-

Casting Metal Repair Adhesive

-

Type:

-

Two components Adhesive

-

Appearance:

-

Grey Paste + Light Yellow Paste

-

Material:

-

Epoxy Resin+curing Hardner

-

Feature:

-

Waterproof, anti-corrosion,anti-scratch

-

Application:

-

Bonding and repairing metal and metal alloy

-

Full cure time:

-

24 hours

-

Operation time:

-

10 minutes

-

OEM Service:

-

available

-

MOQ:

-

10 cartons

-

Shelf life:

-

1 year

-

Package:

-

100g/color box, 50 color boxes/carton

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

Epoxy ab glue

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

X- DELIGHT

-

Model Number:

-

Casting Metal Repair Adhesive

-

Type:

-

Two components Adhesive

-

Appearance:

-

Grey Paste + Light Yellow Paste

-

Material:

-

Epoxy Resin+curing Hardner

-

Feature:

-

Waterproof, anti-corrosion,anti-scratch

-

Application:

-

Bonding and repairing metal and metal alloy

-

Full cure time:

-

24 hours

-

Operation time:

-

10 minutes

-

OEM Service:

-

available

-

MOQ:

-

10 cartons

-

Shelf life:

-

1 year

-

Package:

-

100g/color box, 50 color boxes/carton

Product Description

Our casting adhesive is a two-component epoxy glue that can be cured quickly at room temperature, good toughness, excellent properties , high bonding strength and fast curing speed.

|

Metal Casting Repair Epoxy Adhesive

|

PU - 8100

|

|

|

Excellent Waterproof 1:1 Industrial Metal Repair Adhesive

|

|

|

|

Features

|

Fast curing, high strength, waterproof, acid and alkali resistance, oil resistance, solvent resistance, excellent performance.

Non-flammable, non-shrinkable, can be filled, can be ground, can be drilled.

It is the best choice for bonding glass, decorative panels and bonding displays.

|

|

|

Features

|

Good toughness,

Fast curing speed

High bonding strength

Excellent performance

|

|

|

Packing details

|

|

|

|

100g/ color box , 50color boxes/carton

|

|

|

|

Shelf Life

|

1 year

|

|

Application

It can be used for pores, sand holes, pits, d

efects found during processing,

such as cast iron, cast steel, and cast aluminum. Also can be used as general structural glue.

Instructions

Precautions

1.Please pay more attention to the

exothermic reaction

when operating glue.

1) The more glue amount, the faster the curing speed.

2) The higher temperature, the faster the curing speed, on the contrary, the lower the ambient temperature cause slow curing speed.

3) It must be formulated in strict accordance with the specified ratio t

o achieve better performance.

2.

Keep away from children.

3.R

ecommend to use in a well-ventilated place

4.R

inse immediately with clean water and seek medical attention when touch eyes.

5.W

ipe it with a cloth and rinse with water when touch skin.

Product Paramenters

Below relevant product data and descriptions provided in this document are based on a specific environment Under test or our current knowledge and experience. The actual application of products is affected by artificial or natural factors such as substrates, processes, equipment, environment, storage, transportation, user experience, etc.

|

|

Typical Paramenters

|

Range

|

||

|

Characteristics Before Curing

|

|

|

||

|

A component

|

|

|

||

|

Appearance

|

Silver gray paste

|

|

||

|

Base Chemical Composition

|

Epoxy resin

|

|

||

|

B component

|

|

|

||

|

Appearance

|

Light yellow paste

|

|

||

|

Base Chemical Composition

|

Amine curing agent

|

|

||

|

Mixing Characteristics

|

|

|

||

|

Mixing Weight Ratio

|

A : B = 5.5 : 4.5

|

|

||

|

Mixing Volume Ratio

|

A : B = 1 : 1

|

|

||

|

Pot Life (min)(100g@25℃)

|

10

|

5 ~ 15

|

||

|

Characteristics After Curing

|

|

|

||

|

Appearance

|

Grey solid

|

|

||

|

Curing time (min)

|

45

|

|

||

|

(1-3mm Thin Layer peeling paper surface time)

|

|

|

||

|

Shear Strength (MPa)(GB/T7124-2008)

|

23.21

|

≥15

|

||

|

Hardness (D)(GB/T2411-2008)

|

82

|

≥78

|

||

|

Working temperature (℃)

|

-40-150

|

|

||

Company Introduction

Chandor is biggest adhesive manufacturer in China Fujian and established in 1990. We have 40,000 square meters production base, more than 50 professional technicians working together with 300 skilled workers to provide you high-tech products and professional technical services.

Our Services & Strength

1.Chandor

has established stable cooperation with global upstream suppliers of chemical raw materials to ensure the purity and stable performance of raw materials.

2.

Chandor has 30 years of technical accumulation and experience in the field of industrial adhesives.

3.Chandor R & D and application engineers work closely together during the product development and design phase, on-site application process and material matching test phase to ensure that all technical issues are properly resolved from the beginning.

Certifications

Chandor has passed ISO9001: 2000 quality management system certification; ISO14001: 2004 environmental management system certification; OHSAS18001: 1999 occupational health and safety management system certification

.

Related Products

FAQ

Hot Searches