- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V(support customized)

-

Dimension(L*W*H):

-

6300*700*1300mm

-

Weight:

-

1500 kg

-

Feeding width:

-

238mm

-

Product Name:

-

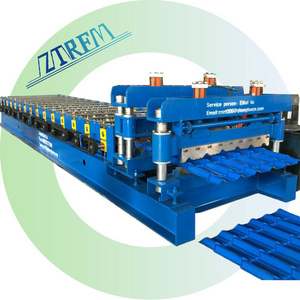

Gusset Plate Roll Forming Machine

-

Shaft diameter:

-

50mm

-

Chain:

-

0.6 inches

-

Number of lanes of molding machine:

-

18 rows

-

Hydraulic station oil pump:

-

3KW

-

Length determination accuracy:

-

±2mm

-

Electric control box:

-

PLC control system

-

Cutter material:

-

Chromium 12 Molybdenum Vanadium Hydraulic Guide Post Shearing

-

Roller material:

-

45# steel

-

Certificate:

-

CE, ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V(support customized)

-

Dimension(L*W*H):

-

6300*700*1300mm

-

Weight:

-

1500 kg

-

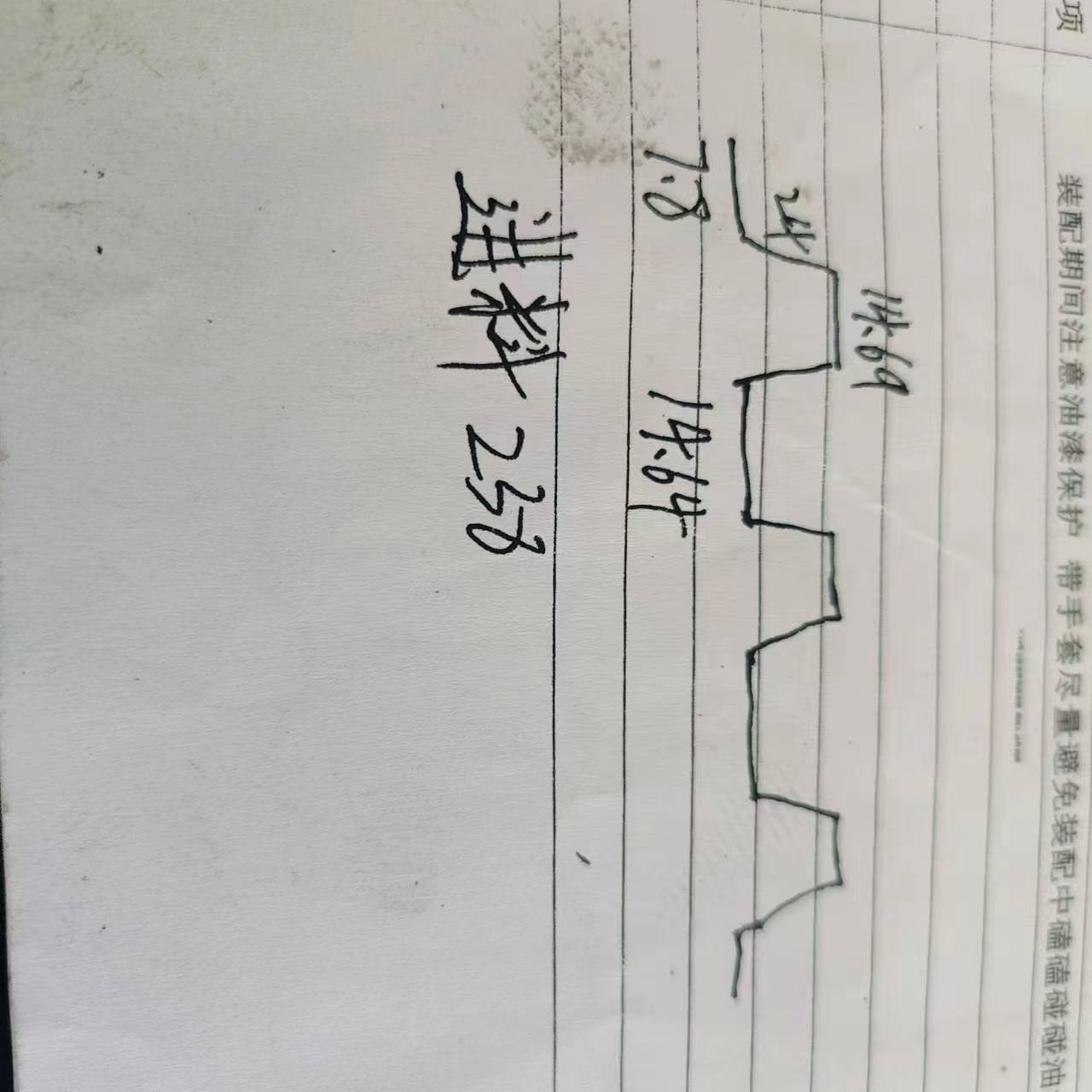

Feeding width:

-

238mm

-

Product Name:

-

Gusset Plate Roll Forming Machine

-

Shaft diameter:

-

50mm

-

Chain:

-

0.6 inches

-

Number of lanes of molding machine:

-

18 rows

-

Hydraulic station oil pump:

-

3KW

-

Length determination accuracy:

-

±2mm

-

Electric control box:

-

PLC control system

-

Cutter material:

-

Chromium 12 Molybdenum Vanadium Hydraulic Guide Post Shearing

-

Roller material:

-

45# steel

-

Certificate:

-

CE, ISO

Product Description

Gusset Plate

Roll Forming Machine

The following are the specifications of the two most common shapes we provide, and the specific shapes can be customized according to customer requirements (punching is optional).

The following are the versions we have sold, you can also send me your drawings, we will customize the machine for you.

Our

Advantanges:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost.

4.Infinite sizing(any size within machine range),help to save material.

5.Optional Punch hole at any position of purlin web side and flange side.

The Working Flow

Manual uncoiler---feeding device---rolling form---speed, length, pieces set by PLC---hydraulic mold post cutting---collection table

|

|

|

|

|

|||||

|

Product name

|

Gusset Plate Roll Forming Machine

|

|

|

|

||||

|

Frame materials

|

350H steel

|

|

|

|

||||

|

Shaft diameter

|

50mm

|

|

|

|

||||

|

Forming roller

|

18row

|

|

|

|

||||

|

Forming shaft

|

Material 45# quenched and tempered

|

|

|

|

||||

|

Max.speed

|

0-15m/min

|

|

|

|

||||

|

Feeding width

|

As Required

|

|

|

|

||||

|

Cutting system

|

Hydraulic Cutting

|

|

|

|

||||

|

Main engine power

|

4KW with cycloidal reducer

|

|

|

|

||||

|

Voltage

|

380V 50 Hz 3 Phase or as your requirements

|

|

|

|

||||

|

Hydraulic oil

|

40# hydraulic oil

|

|

|

|

||||

|

Material of cutting table

|

Cr 12 mould steel with quenched treatment

|

|

|

|

||||

|

Applicable industries

|

Commercial space background walls, outdoor door heads, indoor and outdoor suspended ceilings for decoration

|

|

|

|

||||

|

|

|

|

|

|||||

Feeding table

Electric control cabinet, PLC fully automatic control, text screen, realize human-computer interaction and reduce labor consumption.

Material of the roller: High grade No.45 forged steel

Roller station: 18 rows

Thickness of feeding material: 0.3-0.8mm

Chrome 12 mold steel, hydraulic shearing, single cylinder design, integrally formed shearing head, no welding seams or holes

.

If you are interested in our products, please do not hesitate, you can contact us directly, I believe we will have a good cooperation.

Details Images

Our Advantages

Hot Searches