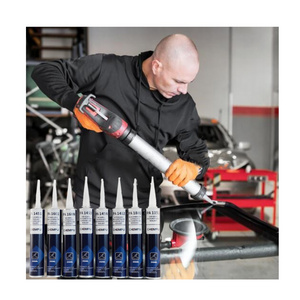

Application field

All kinds of vehicle windshield glass bonding, skin bonding and other parts of high strength bonding. Applicable substrates include glass, glass Steel, steel, aluminum alloy (including painted), etc.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

AM-1206

-

Type:

-

Adhesives and sealants

-

Product name:

-

PU Sealant

-

Application:

-

For Automotive Glass

-

Keywords:

-

PU Sealant

-

MOQ:

-

1 KG

-

Use:

-

Automotive Glass

-

Quality:

-

High-Quality

-

Delivery time:

-

7-15days

-

OEM:

-

Support

-

Storage:

-

Cool Dry Place

-

Packing:

-

Carton

Quick Details

-

Other Names:

-

PU Sealant

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shanquan

-

Model Number:

-

AM-1206

-

Type:

-

Adhesives and sealants

-

Product name:

-

PU Sealant

-

Application:

-

For Automotive Glass

-

Keywords:

-

PU Sealant

-

MOQ:

-

1 KG

-

Use:

-

Automotive Glass

-

Quality:

-

High-Quality

-

Delivery time:

-

7-15days

-

OEM:

-

Support

-

Storage:

-

Cool Dry Place

-

Packing:

-

Carton

Product Description

Product Information Introduction

Product characteristics

Mountain Spring AM-1206 is a single component polyurethane adhesive of medium and high viscosity and high strength. The moderate viscosity is easy to be applied.High bonding strength and good flexible sealing characteristics

Construction Guide

1. Surface cleaning:

The bonding surface should be clean, dry, free of grease and dust. If the surface is prone to peeling rust, it should be removed with a metal brush in advance Organic solvents such as acetone can also be used to wipe the surface. According to the different substrate and the preliminary test results, decide whether to choose the matching activation

Agent and/or primer, and brush with reference to its technical instructions.

2. Construction:

Hard packaging: pull back the easy to pull cover, Pierce the film at the mouth of the cylinder, screw on the matching rubber nozzle, and put the glue into the hard packaging glue gun;

Flexible packaging: Put the glue into the flexible packaging glue gun and cut off the seal, attach the matching rubber nozzle, and tighten the muzzle cover;

Drum packaging: depends on the extruding pump and gluing equipment;

According to the construction requirements, the rubber nozzle will be cut into a triangle or round, can be point or strip sizing, and must be installed within the dry time of the rubber surfaceAnd locate.

Notes

- When the ambient temperature is lower than 10℃ or the glue production speed cannot meet the process requirements, it is recommended to bake the adhesive in the oven at 40℃ ~ 60℃ for 1h ~At 3h, it is recommended to use supporting equipment to maintain continuous heating of about 40 ° C ~ 60 ° C.

- If the adhesive parts are heavy, use auxiliary tools (such as adhesive tapes, positioning blocks, and bandages) to locate the parts after sizing.

- Optimal construction environment: temperature 15℃ ~ 30℃, relative humidity 40% ~ 65%RH.

- In order to ensure good bonding and sealing effect and the compatibility of the product with the substrate, the actual substrate should be tested in the corresponding environment in advance.

Specification

|

item

|

value

|

|

Other Names

|

PU Sealant

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Classification

|

Hot Melt Adhesives

|

|

Main Raw Material

|

Silicone

|

|

Usage

|

Construction, Packing, Woodworking

|

|

Brand Name

|

Shanquan

|

|

Model Number

|

AM-1206

|

|

Type

|

Adhesives and sealants

|

|

Product name

|

PU Sealant

|

|

Application

|

For Automotive Glass

|

|

Keywords

|

PU Sealant

|

|

MOQ

|

1 KG

|

|

Use

|

Automotive Glass

|

|

Quality

|

High-Quality

|

|

Delivery time

|

7-15days

|

|

OEM

|

Support

|

|

Storage

|

Cool Dry Place

|

|

Packing

|

Carton

|

Hot Searches