- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V

-

Power:

-

28KW/set

-

Dimension(L*W*H):

-

11700*5200*1888mm(L*W*H)

-

Weight:

-

4000 KG

-

Product name:

-

Automatic hanking machine

-

Hank numbers:

-

16hanks * 4

-

Banding distance:

-

180mm

-

Hank weight:

-

Max.350g

-

Hank width:

-

80~120mm(adjustable)

-

Hank perimeter:

-

1700~2100mm(adjustable)

-

Hanking speed:

-

Max.400rpm

-

Banding numbers:

-

3~6adjustable each side

-

Mesh type:

-

1~3(adjustable)

-

Total power:

-

28KW

Quick Details

-

Applicable Industries:

-

Fancy yarn industry

-

Marketing Type:

-

Hot Product 2023

-

Application:

-

Twisted yarn

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V

-

Power:

-

28KW/set

-

Dimension(L*W*H):

-

11700*5200*1888mm(L*W*H)

-

Weight:

-

4000 KG

-

Product name:

-

Automatic hanking machine

-

Hank numbers:

-

16hanks * 4

-

Banding distance:

-

180mm

-

Hank weight:

-

Max.350g

-

Hank width:

-

80~120mm(adjustable)

-

Hank perimeter:

-

1700~2100mm(adjustable)

-

Hanking speed:

-

Max.400rpm

-

Banding numbers:

-

3~6adjustable each side

-

Mesh type:

-

1~3(adjustable)

-

Total power:

-

28KW

Product Description

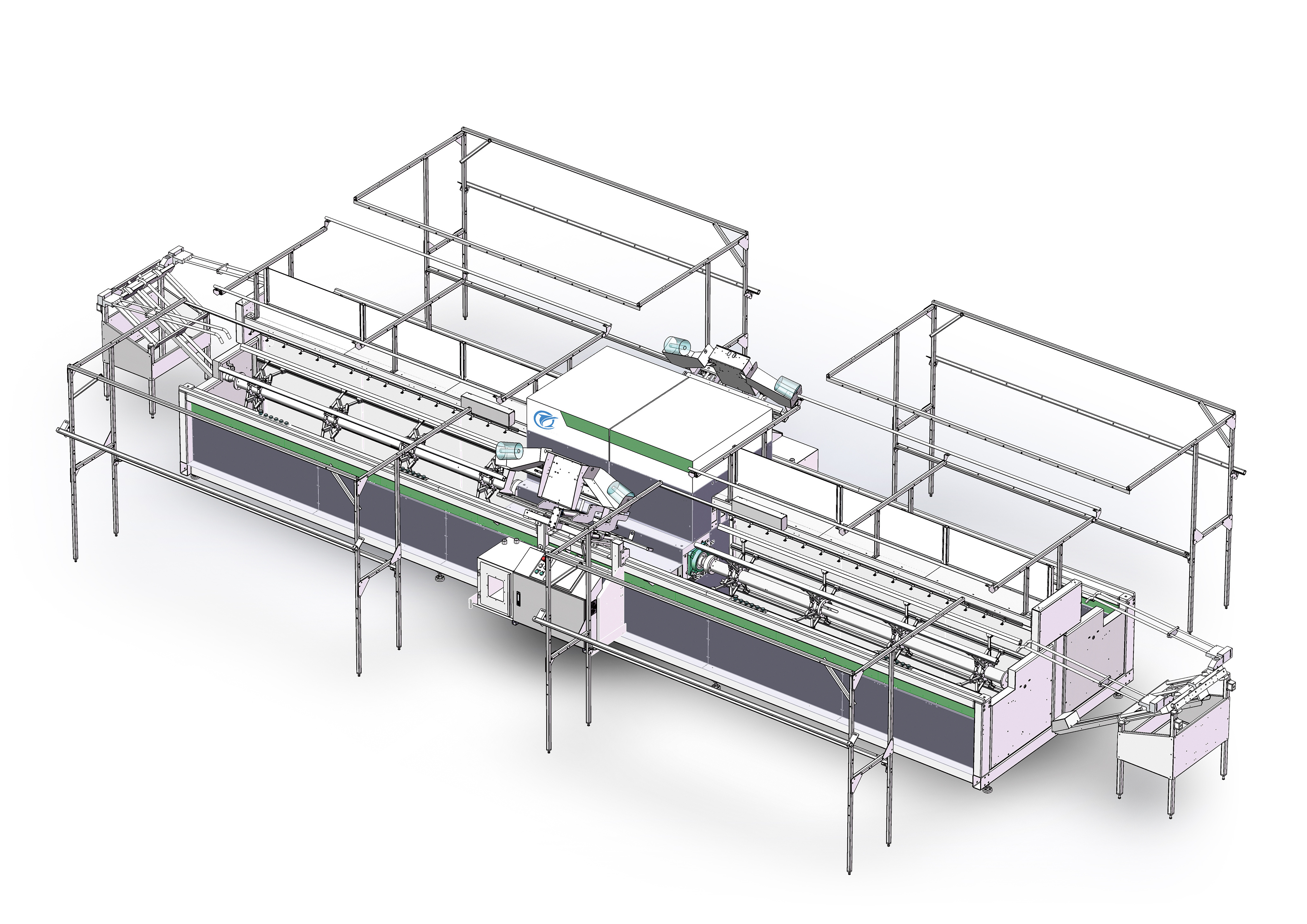

Automatic Hanking Machine

XYJB416 full-automatic high-speed hanking machine is a new product developed by NEW VICTOR for 7 years. It fundamentally changes the traditional banding type. Adopt modern electromechanical integration technology. It can realize the automation of the whole banding process, thus significantly improving the efficiency of hanking and reducing workers and labor intensity of workers. The machine can easily adjust the hank width, mesh type, and banding number to achieve the requirements of different yarn hanking processes. Meanwhile, it has high reliability, economy, and operability. Save labor, reduce labor intensity, improve the efficiency and productivity of single machine operation, and improve comprehensive production efficiency.

Features:

• Creel frame length can be adjusted automatically, which is suitable for most yarns in the banding process.

• Creel frame shaft and hank moving are driven by an independent high-speed servo motor, which can determine length accurately. Good rigidity of creel frame shaft, running stable, Max speed could be 400 RPM;

• Automatic fixing yarn onto the machine, high-speed running, banding, doffing, determining length & weight, etc. Without manual intervention, which dramatically reduces the labor intensity of workers.

• Banding width, mesh type and banding numbers can be freely adjusted for different hanking processes of yarns.

• Banding trolley is simple and easy to maintain, switching automatic or manual quickly, and banding is stable and reliable.

• Photoelectric yarn detector is sensitive and reliable. Automatic yarn broken device in each section. Reduce the weight deviation of the hank.

• Automatic calculation of output, automatic stop when full circle, master production data in the whole process;

• Both hanking and banding adopt the sharing mode, which reduces additional losses and improves energy efficiency.

• Raw material creel design simple and easy operation, more suitable for actual production conditions.

Specification

|

item

|

value

|

|

Applicable Industries

|

Fancy yarn industry

|

|

Showroom Location

|

Egypt

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot Product 2023

|

|

Warranty of core components

|

3 years

|

|

Core Components

|

PLC

|

|

Condition

|

New

|

|

Automatic Grade

|

Automatic

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Power

|

28KW/set

|

|

Dimension(L*W*H)

|

11700*5200*1888mm(L×W×H)

|

|

Weight

|

4000KG

|

|

Warranty

|

3 years

|

|

Product name

|

Automatic hanking machine

|

|

Hank numbers

|

16hanks * 4

|

|

Banding distance

|

180mm

|

|

Hank weight

|

Max.350g

|

|

Hank width

|

80~120mm(adjustable)

|

|

Hank perimeter

|

1700~2100mm(adjustable)

|

|

Hanking speed

|

Max.400rpm

|

|

Banding numbers

|

3~6adjustable each side

|

|

Mesh type

|

1~3(adjustable)

|

|

Total power

|

28KW

|

Packing & Delivery

sea-worthy packaging

Hot Searches