- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

10000 KG

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

After-sales Service Provided:

-

Overseas service center available, Online support

-

Blasting cabinet:

-

Color steel tile and abrasion resistant rubber liner

-

Blast pot:

-

300L to 800L available

-

Floor:

-

Waffle floor hopper

-

Dust collector:

-

Omron/Scheider/ABB/NSK

-

Blast pot technology:

-

Pneumatic control abrasive brake valve

-

Screw conveyor raw material:

-

Mn16 steel

-

Bucket elevator:

-

Adopted motor cage

-

Separation system:

-

Overflow inductive curtain multi-level air separator

-

Moto:

-

SIEMENS

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINGGONG

-

Core Components:

-

Blasting pot

-

Weight (KG):

-

10000 KG

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

After-sales Service Provided:

-

Overseas service center available, Online support

-

Blasting cabinet:

-

Color steel tile and abrasion resistant rubber liner

-

Blast pot:

-

300L to 800L available

-

Floor:

-

Waffle floor hopper

-

Dust collector:

-

Omron/Scheider/ABB/NSK

-

Blast pot technology:

-

Pneumatic control abrasive brake valve

-

Screw conveyor raw material:

-

Mn16 steel

-

Bucket elevator:

-

Adopted motor cage

-

Separation system:

-

Overflow inductive curtain multi-level air separator

-

Moto:

-

SIEMENS

Steel Cleaning Sand Blasting Room/Sandblast Booth/Shot Blaster

Product Description

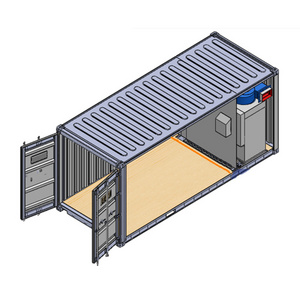

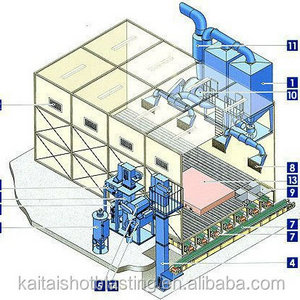

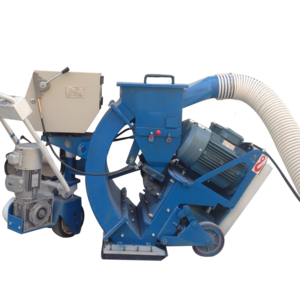

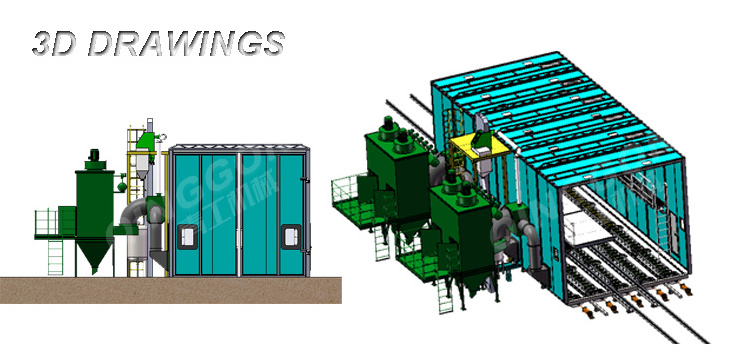

☆Types

Genaral purpose, rail car, portable container, heavy duty industrial, etc.

☆Wall of sandblasting room

50mm thick noise attenuation sandwich panel with glass wool interlayer and abrasion-resistant rubber liner. Antiflaming, innocuity.

☆Structure of blasting room

Modularization design, welded-square-tubes frame.

☆Light

LED lamps, energy saving

☆Sandblasting pot volume

0.3-0.7m3

☆Blast gun

Number: 1-4

Nozzle Diameter: 0.8-1.2mm

☆Door

Double winged swinging door or roller shutter door

☆Abrasive recovery system

1.Sweep/Shovel chute type

2.Single screw partial reclaim system

3.L shaped partial reclaim system

4.H shaped partial reclaim system

5.U shaped partial reclaim system

6.Full floor partial reclaim system

☆Features

Remove scale, rust and welding slag, increase adhesion of coating.

Rust removal grade: SA2.0-2.5.

☆Dust collector

Settling chamber + cartridge-type dust collector

Cartridge filter service time: 5 years

☆Steel shot

Steel shot, cut wire shot, water glass sand, garnet. 0.6-2.0mm

Specification

|

Wall Material

|

Transfer System

|

Lights

|

Inner Protection

|

Floor Recovery type

|

Air blast pot volume

|

|

Glass fiber cotton

or container

|

Rail work car optional

|

LED

|

Rubber sheeting on walls

|

Manual, Partial automatic, Full automatic

|

300-700 L

|

Company Profie

With 45 years experience of innovating and producing, QINGGONG machinery is a professional manufacturer of wheel blast/air blast machines.

Qinggong machinery have a R&D team with 30 years experience, 50 workers and a factory covering an area of 30,000 ㎡.

Untill 2019, Qinggong machinery have produced 5000+ sets of various kinds of wheel blast, air blast machines for customers from more than 50 different countries and some major factories in China, like LongGong, SANY, TISCO, etc.

TREATING SURFACE, PEENING FUTURE.

has been the spirit of Qinggong machinery for decades. With our determined and responsible attitude, we have the confidence of providing the better surface treatment solutions for your industry.

FAQ

Q:How to choose balst machine type?

A:Please tell the information of your work-piece and productivity, experienced engineer will suggest.

Q:How to choose abrasive?

A:Various kinds abrasive with different size: steel shot, cut wire shot, stainless steel shot, etc. Choose according to workpiece.

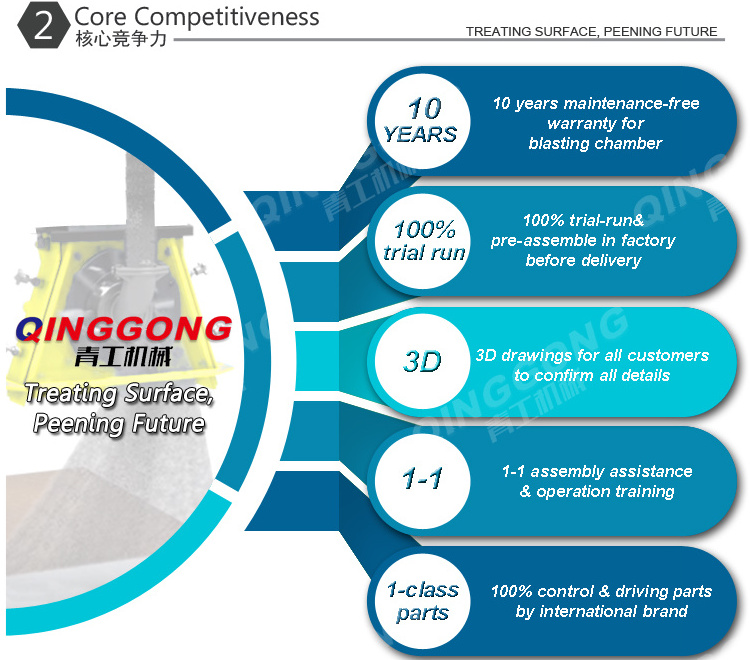

Q:Quality warranty?

A:1 year for whole machine, 10 years for blasting chamber

Q:Is foundation pit essential?

A:Up to machine size and workshop

Q:How many workers to operate the machine?

A:1-2, up to the machine.

Q:Install assistance?

A:1-1 install assistance & operation training on site by experienced engineer.

Q:After sale service?

A:Full stock for spare parts, regular after sale service.

Hot Searches