- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Dimension(L*W*H):

-

5030x2270x2900mm

-

Power (kW):

-

11

-

Weight (KG):

-

6000 KG

-

Applicable Industries:

-

GEO, Insulation, 2D/3D Cut

-

Product Name:

-

EPS Block Moulding Machine

-

Raw material:

-

expanded polystyrene(EPS)

-

Function:

-

moulding all the shape kinds of EPS products

-

Feature:

-

Full Automatic/running stable/vacuum

-

Application area:

-

GEO/Insulation/2D3D Cut

-

HS code:

-

84778000

-

Control system:

-

PLC+touch panel

-

After-sales Service Provided:

-

engineer field installation

-

Local Service Location:

-

vietnam/middle east/turkey

-

After Warranty Service:

-

Online support/engineer field installation

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Bes

-

Machine Type:

-

EPS Block Machine

-

Voltage:

-

380

-

Dimension(L*W*H):

-

5030x2270x2900mm

-

Power (kW):

-

11

-

Weight (KG):

-

6000 KG

-

Applicable Industries:

-

GEO, Insulation, 2D/3D Cut

-

Product Name:

-

EPS Block Moulding Machine

-

Raw material:

-

expanded polystyrene(EPS)

-

Function:

-

moulding all the shape kinds of EPS products

-

Feature:

-

Full Automatic/running stable/vacuum

-

Application area:

-

GEO/Insulation/2D3D Cut

-

HS code:

-

84778000

-

Control system:

-

PLC+touch panel

-

After-sales Service Provided:

-

engineer field installation

-

Local Service Location:

-

vietnam/middle east/turkey

-

After Warranty Service:

-

Online support/engineer field installation

Products Description

BES Automatic PLC EPS Polystyrene Expander Block Machine Styrofoam Molding For Buildings Production Line Wall Roof Insulation

Space between foaming beads is maintained approximately 40% even if the beads fully fill a moulding machine. Heating the beads with steam makes the beads be foamed again The evaporation of volatile material in the beads causes the volumetric expansion,eliminating space between beads. This thermally fuses the beads to each other to produce blocks with shapes identical to the space in the moulding machine.

Block moulds are made in various size with different cavity volume as per customer different requirement .

BES Automatic PLC EPS Polystyrene Expander Block Machine Styrofoam Molding For Buildings Production Line Wall Roof Insulation

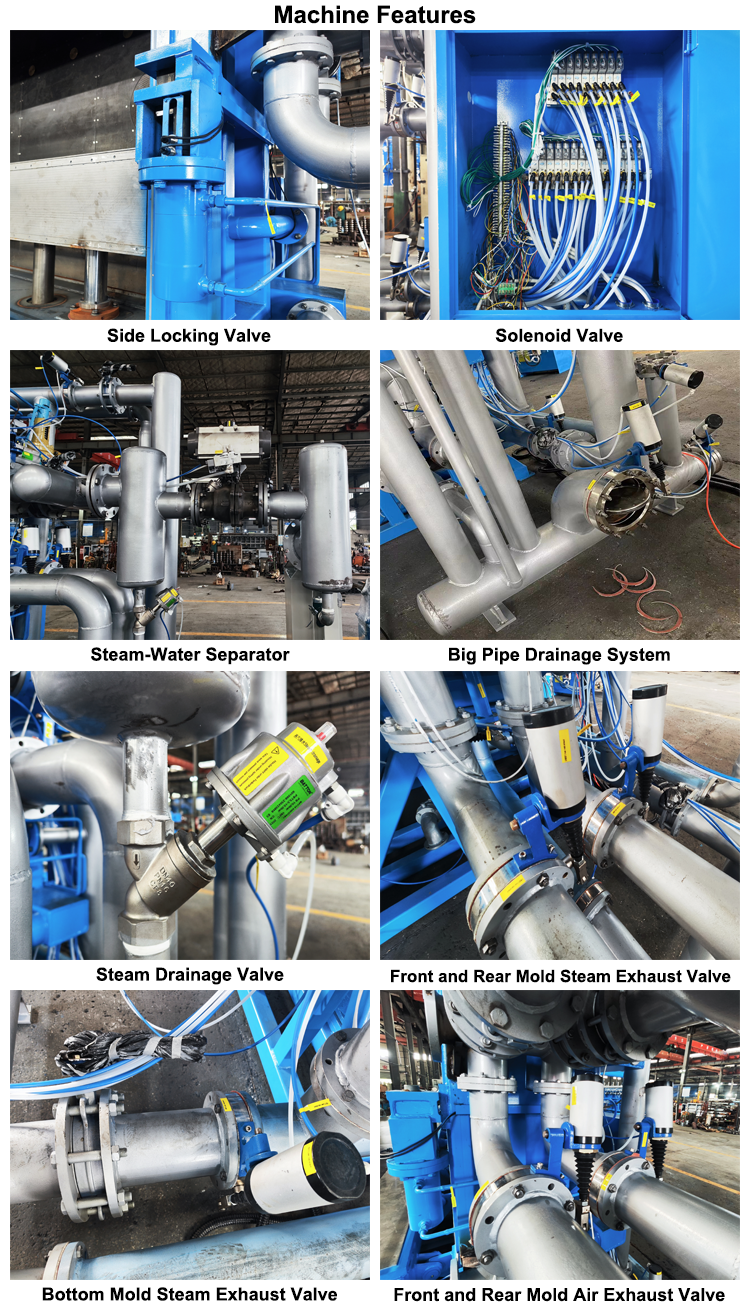

Features and advantages of BES-PBF-Series EPS Block Moulding Machine

1. High strength frame of block moulding machine; keep more safety test pressure

2. Al Plate with Teflon Coating or stainless steel for block Chamber

3. Less de-form & accurate machining process keep non-leakage instead of changing sealing frequently

4. All gauges , solenoid valve are used world brand’s ones for double safety

5. Mitsubishi PLC, Schneider touch screen for easy operation

6. Automatic working process

7. Energy-saving system

1. High strength frame of block moulding machine; keep more safety test pressure

2. Al Plate with Teflon Coating or stainless steel for block Chamber

3. Less de-form & accurate machining process keep non-leakage instead of changing sealing frequently

4. All gauges , solenoid valve are used world brand’s ones for double safety

5. Mitsubishi PLC, Schneider touch screen for easy operation

6. Automatic working process

7. Energy-saving system

|

Technical Datas

|

|

|

|

|

|

|

||||||

|

Item

|

|

BES-PBZ-2000

|

BES-PBZ-3000

|

BES-PBZ-4000

|

BES-PBZ-6000

|

BES-PBZ-8000

|

||||||

|

Mould Cavity Size

|

|

2040×1240×1030(mm)

|

3060×1240×1030(mm)

|

4080×1240×1030(mm)

|

6100×1240×1030(mm)

|

8120×1240×1030(mm)

|

||||||

|

Block size

|

|

2000×1200×1000(mm)

|

3000×1200×1000(mm)

|

4000×1200×1000(mm)

|

6000×1200×1000(mm)

|

8000×1200×1000(mm)

|

||||||

|

Steam

|

Entry

|

DN100

|

DN100

|

DN150

|

DN150

|

DN200

|

||||||

|

|

Consumption

|

30~50kg/cycle

|

50~70kg/cycle

|

60~90kg/cycle

|

100~130kg/cycle

|

120~170kg/cycle

|

||||||

|

|

Pressure

|

0.8Mpa

|

0.8Mpa

|

0.8Mpa

|

0.8Mpa

|

0.8Mpa

|

||||||

|

Compressed Air

|

Entry

|

DN40

|

DN40

|

DN40

|

DN40

|

DN40

|

||||||

|

|

Consumption

|

1.5-2m3/cycle

|

1.8-2.2m3/cycle

|

2-2.5m3/cycle

|

2--3m3/cycle

|

2.5--3m3/cycle

|

||||||

|

|

Pressure

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

0.6Mpa

|

||||||

|

Drainage

|

Vacuum Drain

|

¢125mm

|

¢125mm

|

¢125mm

|

¢125mm

|

¢125mm

|

||||||

|

|

Steam vent

|

¢150mm

|

¢200mm

|

¢200mm

|

¢250mm

|

¢300mm

|

||||||

|

|

Condensate

|

¢100mm

|

¢100mm

|

¢100mm

|

¢100mm

|

¢100mm

|

||||||

|

|

Blower Outlet

|

¢125mm

|

¢125mm

|

¢150mm

|

¢150mm

|

¢150mm

|

||||||

|

Cooling Water

|

Entry

|

DN40

|

DN40

|

DN40

|

DN40

|

DN40

|

||||||

|

|

Consumption

|

0.2-0.4m3/cycle

|

0.4-0.6m3/cycle

|

0.6-0.8m3/cycle

|

0.8-1m3/cycle

|

1-1.2m3/cycle

|

||||||

|

|

Pressure

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

||||||

|

Throughput

|

15kg/m3

|

5min/cycle

|

6min/cycle

|

7min/cycle

|

8min/cycle

|

8min/cycle

|

||||||

|

Connected Load

|

|

20.5-24.5KW

|

20.5-24.5KW

|

24.5-35.5.5KW

|

24.5-35.5KW

|

35.5-43.5KW

|

||||||

|

Overall Dimension

|

mm

|

5700×4000×2850

|

7200×4500×3000

|

11000×4500×3000

|

12600×3960×2906

|

15700×4600×3400

|

||||||

|

Weight

|

|

6000 kg

|

7200 kg

|

12000 kg

|

15000 kg

|

18500 kg

|

||||||

|

Room Height Required

|

|

6000mm

|

6000mm

|

6000mm

|

6000mm

|

6000mm

|

||||||

|

Note:We make adjustable type and customize machines according to customer’s requirement

|

|

|

|

|

|

|

||||||

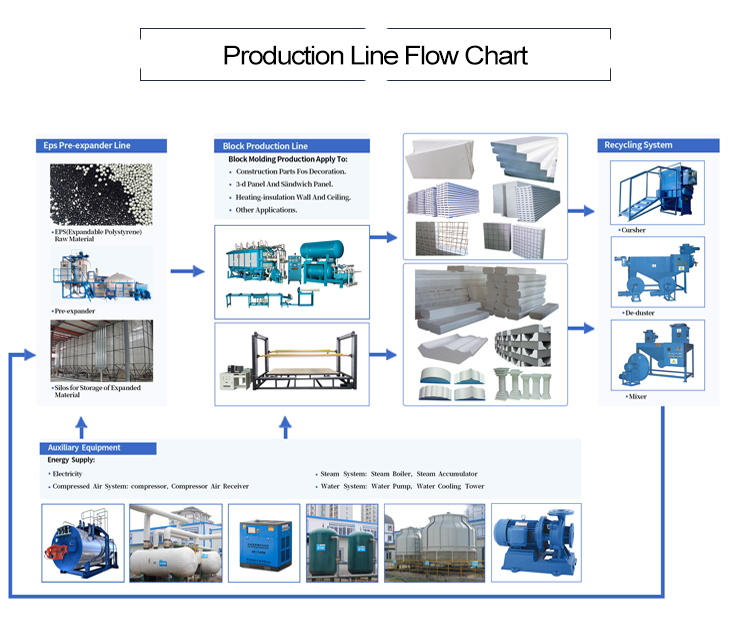

The Production Line

Hot Searches