- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

15 kW

-

Production Speed(times/h):

-

180

-

Power Supply:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

no

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

2700*1500*1800mm

-

Weight (T):

-

1.6 T

-

Name:

-

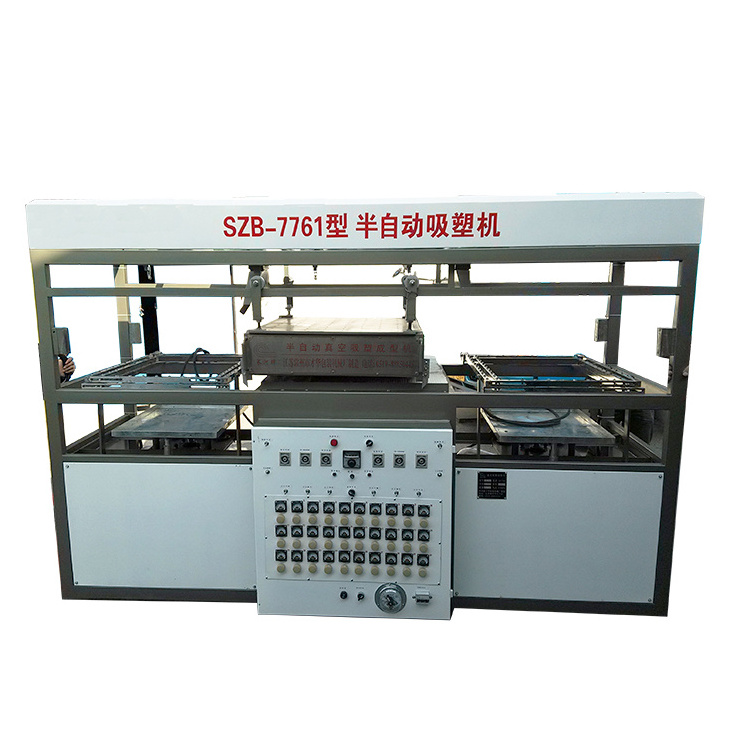

Semi automatic vacuum forming machine for customized packaging trays

-

Keyword:

-

vacuum forming machine

-

Application:

-

Tray

-

Color:

-

Customized

-

Forming Height:

-

180mm

-

Model:

-

SZB-7761D

-

Max forming Length:

-

710mm

-

Forming Width:

-

550mm

-

Weight:

-

1.6T

-

Use for:

-

PC Sheet

-

Certification:

-

CE

Quick Details

-

Max.Forming Height(mm):

-

180 mm

-

Forming Width (mm):

-

550 mm

-

Forming Length (mm):

-

710 mm

-

Heating Power (kW):

-

15 kW

-

Production Speed(times/h):

-

180

-

Power Supply:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

no

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

2700*1500*1800mm

-

Weight (T):

-

1.6 T

-

Name:

-

Semi automatic vacuum forming machine for customized packaging trays

-

Keyword:

-

vacuum forming machine

-

Application:

-

Tray

-

Color:

-

Customized

-

Forming Height:

-

180mm

-

Model:

-

SZB-7761D

-

Max forming Length:

-

710mm

-

Forming Width:

-

550mm

-

Weight:

-

1.6T

-

Use for:

-

PC Sheet

-

Certification:

-

CE

Product Description

principle:

The plastic sheet or plate is heated and softened, and then sealed with the mold. By vacuuming, the softened plastic is stretched closely against the mold surface, and after cooling and hardening, the plastic becomes exactly the same shape as the mold.

The plastic sheet or plate is heated and softened, and then sealed with the mold. By vacuuming, the softened plastic is stretched closely against the mold surface, and after cooling and hardening, the plastic becomes exactly the same shape as the mold.

|

model

|

SZB-4860D

|

SZB-7761D

|

SZB-7761S

|

||

|

Forming length

|

400-600mm(adjustable)

|

500-710mm (adjustable)

|

380-550mm (adjustable)

|

||

|

Forming width

|

300-480mm(adjustable)

|

380-550mm (adjustable)

|

380-550mm (adjustable)

|

||

|

Forming height

|

180mm

|

|

|

||

|

Sheet thickness

|

0.1-3mm

|

|

|

||

|

Production speed

|

2-5 times / minute (depending on product shape and sheet thickness)

|

2-5 times / minute (depending on product shape and sheet thickness)

|

|

||

|

power

|

8-10KW

|

15kw

|

15kw

|

||

|

Heating brick arrangement

|

4*5=20 blocks

|

5 × 6 = 30 blocks

|

|

||

|

Overall size

|

L1000*W1100*H2200mm

|

L2700* W1500 * H1800mm

|

L3200* W1500 * H1800mm

|

||

|

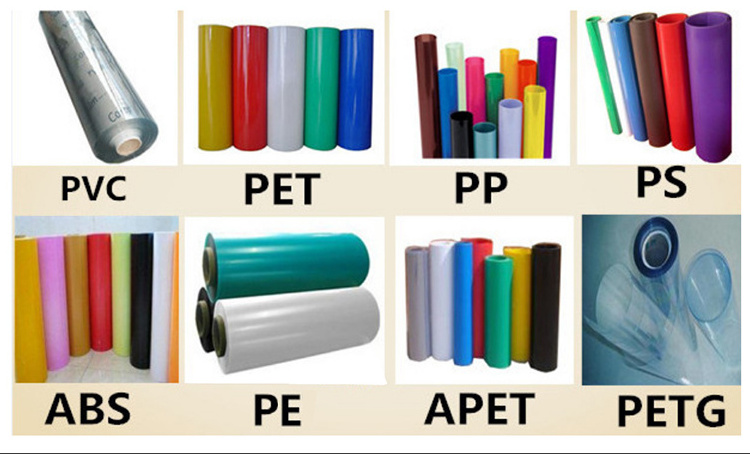

Applicable materials

|

PVC, PP, PS, PET, PE, ABS, etc.

|

|

|

||

|

power supply

|

AC380V / three-phase four-wire 50/60HZ

|

|

|

||

|

Air compressor power

|

4kw (customer-supplied)

|

4kw (customer-supplied)

|

4kw (customer-supplied)

|

||

In addition to the standard models, we can also customize according to the size and function you need,

Working Processes of Vacuum Forming Machine:

Carry materials manually→ clamp the materials → move the material into the oven,(while we can use blow function to keep material not drap down), after the material to soft →take the material to forming area → Bubble blow the material before vacuum (this is important function) → the vacuum will auto start→ open the fan to cold→ separate the model and material →take the material out.

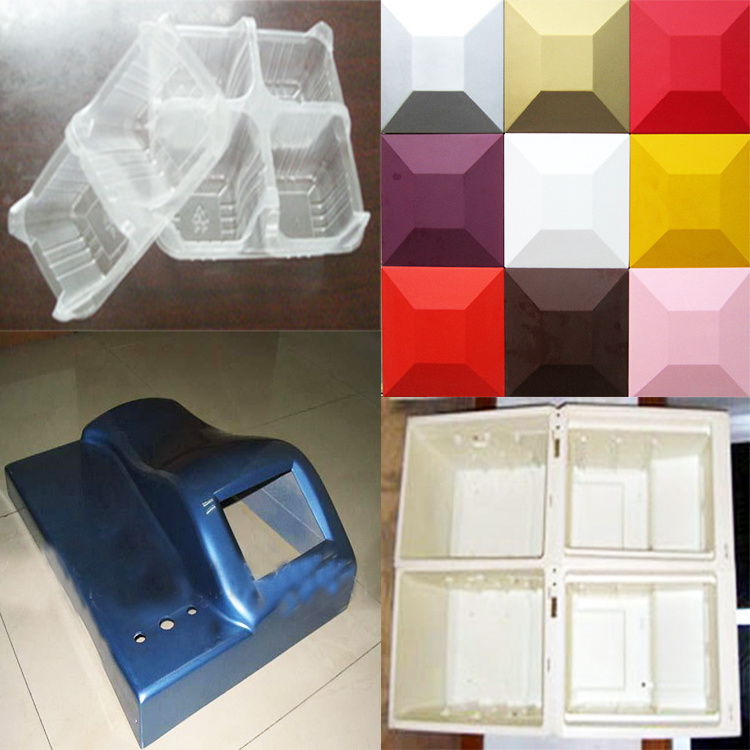

We can also customize various molds

There are generally gypsum molds, copper molds and aluminum molds, each of which has advantages and disadvantages.

Copper mould

Aluminum mold

Aluminum mold

Product Application

Various plastic sheets such as PVC, PE, PP, PS, PET, PETG, ABS, acrylic, etc. can be molded into various shapes of cover boxes, which are widely used in hardware, toys, stationery, tableware, tools, food, electronics, Packaging of medicines or molding of thin plastic products.

Main Features

main features

1. Independent temperature control, using far-infrared ceramic heating elements to heat, can individually control the temperature of each heating element, and can turn off any heating element, and is equipped with a mold function, which is more suitable for the production of complex products.

2. The secondary vacuum is more suitable for producing difficult products.

3. Equipped with wide-mouth fan, it can ensure good cooling of the product, fast forming speed and high production efficiency.

Sample

It can blister PVC, PP, PS, PET, PE, ABS and other plastic sheets into various shapes of cover boxes, which are widely used in the packaging of hardware, toys, stationery, tableware, tools, food, electronics, medicines, etc. . The product is transparent and beautiful, anti-corrosion and moisture-proof, and can also produce ceilings, floors, billboards, automobile plastic parts, etc.

Customer Feedback

More choices

Packing&Shipping

Packing:

We supply strong plywood case packaging machines, safty and meet internetional export package standard.

Delivery:

For machine is big and heavy parcel, and different country with different delivery cost. And the best delivery we suggest is by sea, so the delivery cost will be depended on your destination port. The price show on the website just the machine EXW price, please understand.

Company Introduction

Changzhou Caihua Packaging Machinery Factory established in 2002, Is a professional manufacturer of plastic vacuum forming machine, semi-automatic plastic molding machine,high-frequency machine,shrink packaging machine,vacuum packaging machine, sealing machine, skin packaging machine, and so on .The machine can be customized.We have more than 18 years of industry experience, with independent research and development team, quality assurance.specializing in plastic packaging machinery manufacturing, accumulated a wealth of experience, with the ability to develop their own design and production. Factory direct sales eliminate middlemen, communication more timely. Also can be customized according to customer needs, equipped with peripheral products, one-stop service, provide professional solutions, to solve your worries.

Pre-sale services:

1. Providing professional technical support, new project design, automatic special machine design.

2. Supply project book, machine drawing, make and testing samples for customer.

3. If you have any question please contact us online or send us email, we promise reply at the first time!

4. If you have immidertly question just call me or visit us take a details meeting are warmly welcome.

Sale of services:

1. We promise honest and fair of machine quality, parts good, and price good, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. We supply 1 years warranty and all life of machine working technology service.

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts.

FAQ

Q:Are you a manufacture?

A:Yes, We are manufacture, all machines is ourself design and manufacture, we can provide customize service according to your requirement.

Q:Where is your factory? Can I visit your factory?

A:Our factory is located on Changzhou which near Shhanghai . We are warmly welcome you to visit our factory, we can pick you up when you come to Changzhou Benniu International Airport.

Q:How to buy your machine?

A:Please send me inquiry from my alibaba website, after confirm with machine model and price, we will sign a PI to confirm our order, when we get your first deposit start manfuacture machine, when we got your full payment arrange packing and shipping to you.

Q:How to contact you?

A:You can click the "Contact Supplier" in the top of this page or contact me from the buttom contact info, you can add my skype .

Q:What about your warranty?

A:Our warranty is 1 years, and full life technology service.

Q:How long we will get the machine?

A: Delivery time up machine machine model, standard machine normally can shipping out within 10days, special machine up to our PI confirmed delivery date. And after shipping you just need wait the ship container arrived to you.

Q:Are we still need to install the machine after we got?

A:All of machine already testing ready, and all parameter is setted ok before we deliver to you, also we can send you video and manual to teach you how to use the machine.

Q:How can you guarantee we receive a good quality?

A:First, we have seriesly inspection process department to control the quality. When the machine was finished,we should send you the inspection video and pictures. You can come to our factory to check and inspect the machine with your sample raw material.

To our friend:

To give you the best service, we need your full products information(products drawing diagrams, material, welding size,

working-efficiency required etc), If you have any question about our products, please feel free contact me, we will try our best to satisfy you!

To give you the best service, we need your full products information(products drawing diagrams, material, welding size,

working-efficiency required etc), If you have any question about our products, please feel free contact me, we will try our best to satisfy you!

Hot Searches