Product Features and Uses:

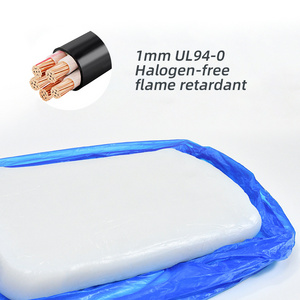

This series of products has a hardness range of 30-80A, good physical properties, good processability, halogenfree, excellent flame retardancy and other characteristics. The products are widely used in the manufacture of electronic and electrical products with flame retardancy and insulation, such as flame retardant gaskets, flame retardant sealing rings, lamp line sleeves and other products.

1

. The physical data listed in the above table are for reference only, if you need the inspection report of the goods, please contact the sales staff;

2. Vulcanization conditions: 170℃×10min, the addition ratio of vulcanizing agent is 1%, and the main components are 2, 5 - Dimethyl-2,5-bis-hexane (bis-two-penta)