- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office, meeting room, hall, show room

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BARDISS

-

Model Number:

-

BDS-C033

-

Type:

-

Ceiling Tiles

-

key words:

-

ceiling design

-

Product name:

-

aluminum ceiling design

-

Series:

-

Clip-in Series

-

Ceiling Design:

-

Perforated Ceilings

-

Size:

-

300*1200 mm

-

Height:

-

19, 25 mm

-

Thickness:

-

0.6~1.0 mm

-

Edge:

-

beveled edge

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design, 3D model design

-

Application:

-

Office, meeting room, hall, show room

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BARDISS

-

Model Number:

-

BDS-C033

-

Type:

-

Ceiling Tiles

-

key words:

-

ceiling design

-

Product name:

-

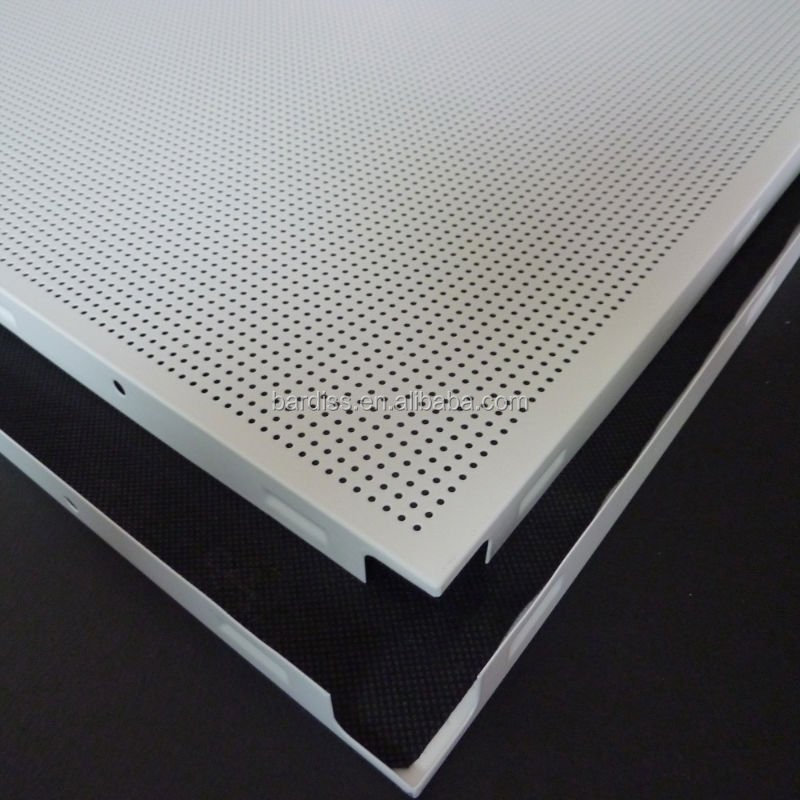

aluminum ceiling design

-

Series:

-

Clip-in Series

-

Ceiling Design:

-

Perforated Ceilings

-

Size:

-

300*1200 mm

-

Height:

-

19, 25 mm

-

Thickness:

-

0.6~1.0 mm

-

Edge:

-

beveled edge

bardiss aluminum ceiling design

Features description:

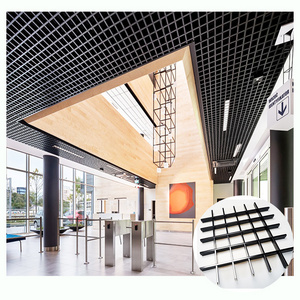

Bardiss clip-in series ceiling, with invisible structure and unique appearance. With strong functional and decorative effects, It has the advantages of stability, easy to install and repair. Corrosion prevention, moisture proof, sound absorbing and inflaming retaeding.

Application:

Large public building, such as office, airport, train station, subway stations, hospitals, hotels etc.

|

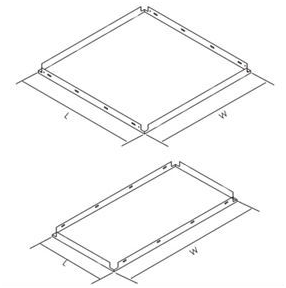

Specification |

Thickness (recommend) |

Height |

Legend |

|

300×300mm |

0.4-1.0mm |

19mm(short edge) 25mm(High edge) |

|

|

300×450mm |

|||

|

300×600mm |

|||

|

300×1200mm |

|||

|

400×400mm |

0.5-1.2mm |

||

|

500×500mm |

|||

|

600×600mm |

|||

|

600×1200mm |

|||

|

Base materials |

Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available |

||

|

Surface treatment |

Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated |

||

|

Type of Surface |

Plain plate or perforated plate is selected according to the actual requirements |

||

Punch Patterns

|

Diameter of holes |

Base thickness |

Diameter of holes |

Base thickness |

|

1.8 mm round holes |

0.45-0.8 |

3.0 mm Square holes |

0.45-0.8 |

|

2.0 mm round holes |

0.45-1.0 |

5.0 mm Square holes |

0.45-0.8 |

|

2.3 mm round holes |

0.45-0.8 |

6.0 mm Square holes |

0.45-1.0 |

|

2.5 mm round holes |

0.45-0.8 |

3.0 different oatten |

0.45-0.7 |

|

6.0 mm round holes |

0.45-1.0 |

3.0 full perforation |

0.45-0.8 |

Accessories & Installation

1) Installing the sideline in the same height.

2) Installing light steel main keel in appreciate, the normal space is 1-1.2m, the hanging distance shall according to the light steel main keel.

3) Binding the light steel main keel with the prepared hanging parts on the triangle keel, then clamp it under the light steel main keel in the vertical direction, the space of the triangle keel accords to the width of the plate. Then it is necessary to adjust it to plane after finish installation.

4) Pressing the two parallel edges into the triangle keel slot, firstly installing the rest plates breadthwise and length ways, make sure they are perpendicular, then installing the rest plates.

5) Pressing the square plates lightly, make sure the gap is perpendicular.

6) Wearing gloves when installing plate, it finger printers or stains remain on the plate, pls remove it off with warm water and detergent, then fry it.

Certification: