- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China, China

-

Brand Name:

-

Baozhen

-

Model Number:

-

BZ-8

-

NAME:

-

Auto parts Hydraulic Carbon steel banjo fitting joint thread nipple

-

Overall Length:

-

40-45-55mm

-

Net Weight:

-

19-21-30-47.5g

-

Interconnection Technique:

-

casting

-

Application:

-

fitting

-

Color:

-

Nature

-

Use:

-

connection

-

Keyword:

-

Auto Engine parts

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Hexagon

-

Place of Origin:

-

China, China

-

Brand Name:

-

Baozhen

-

Model Number:

-

BZ-8

-

NAME:

-

Auto parts Hydraulic Carbon steel banjo fitting joint thread nipple

-

Overall Length:

-

40-45-55mm

-

Net Weight:

-

19-21-30-47.5g

-

Interconnection Technique:

-

casting

-

Application:

-

fitting

-

Color:

-

Nature

-

Use:

-

connection

-

Keyword:

-

Auto Engine parts

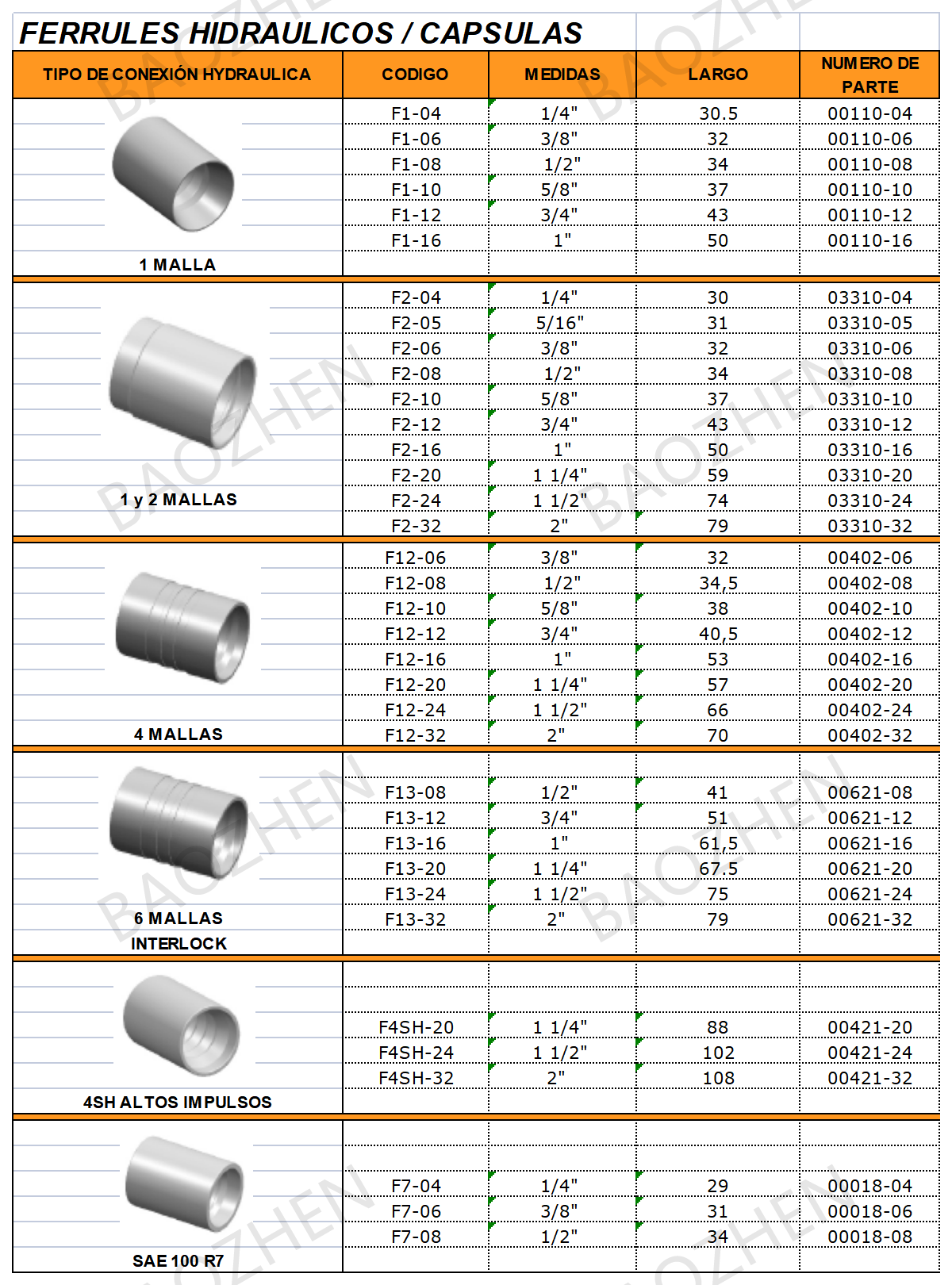

Specification

|

NAME

|

Auto parts External thread banjo hex head ball joint

|

|

Overall Length

|

40-45-55mm

|

|

Net Weigh

|

19-21-30-47.5g

|

|

Interconnection Technique

|

casting

|

|

Place of Origin

|

China

|

|

Application

|

fitting

|

|

Color

|

Nature

|

|

Use

|

connection

|

Product Description

Our factory

Ningbo Baozhen Machinery Co., Ltd.

Manufacturer, Trading Company

Main categories:

Customizing various CNC precision components,

pipe fittings,banjo fitting,flange joint,CNC parts,punching parts

Our factory has the ability to customize a wide range of CNC precision components. We have the expertise and equipment to produce complex parts with high accuracy and consistency. Our team of engineers and technicians work closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs. From simple to intricate designs, we can produce CNC parts for various industries such as aerospace, automotive, medical, and more. Contact us today to discuss your CNC component needs and let us help you bring your ideas to life

At our factory, we follow a strict quality control policy for all the CNC precision components we customize. Each part undergoes a comprehensive inspection process to ensure it meets the required standards. We use advanced testing equipment and techniques to identify any defects or inconsistencies and take corrective measures to address them. Additionally, our after-sales service is excellent, and we provide ongoing support to our clients to ensure they are satisfied with the products they receive. We value our customers' trust and strive to maintain long-lasting relationships by delivering high-quality CNC parts and exceptional service

Product Description

Hot Searches