- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

900x1300x1630mm

-

Weight:

-

1600 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Selective coating machine automatic for PCB

-

Name:

-

PCB conformal coating

-

Coating method:

-

dispensing and coating

-

Positioning accuracy:

-

40μm

-

Tilt Angle:

-

35°(Fixed)

-

Marketing Type:

-

New Product 2022

Quick Details

-

Voltage:

-

AC220-240v, 50-60HZ, 220V / 50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINTAI

-

Dimension(L*W*H):

-

900x1300x1630mm

-

Weight:

-

1600 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Selective coating machine automatic for PCB

-

Name:

-

PCB conformal coating

-

Coating method:

-

dispensing and coating

-

Positioning accuracy:

-

40μm

-

Tilt Angle:

-

35°(Fixed)

-

Marketing Type:

-

New Product 2022

Product Description

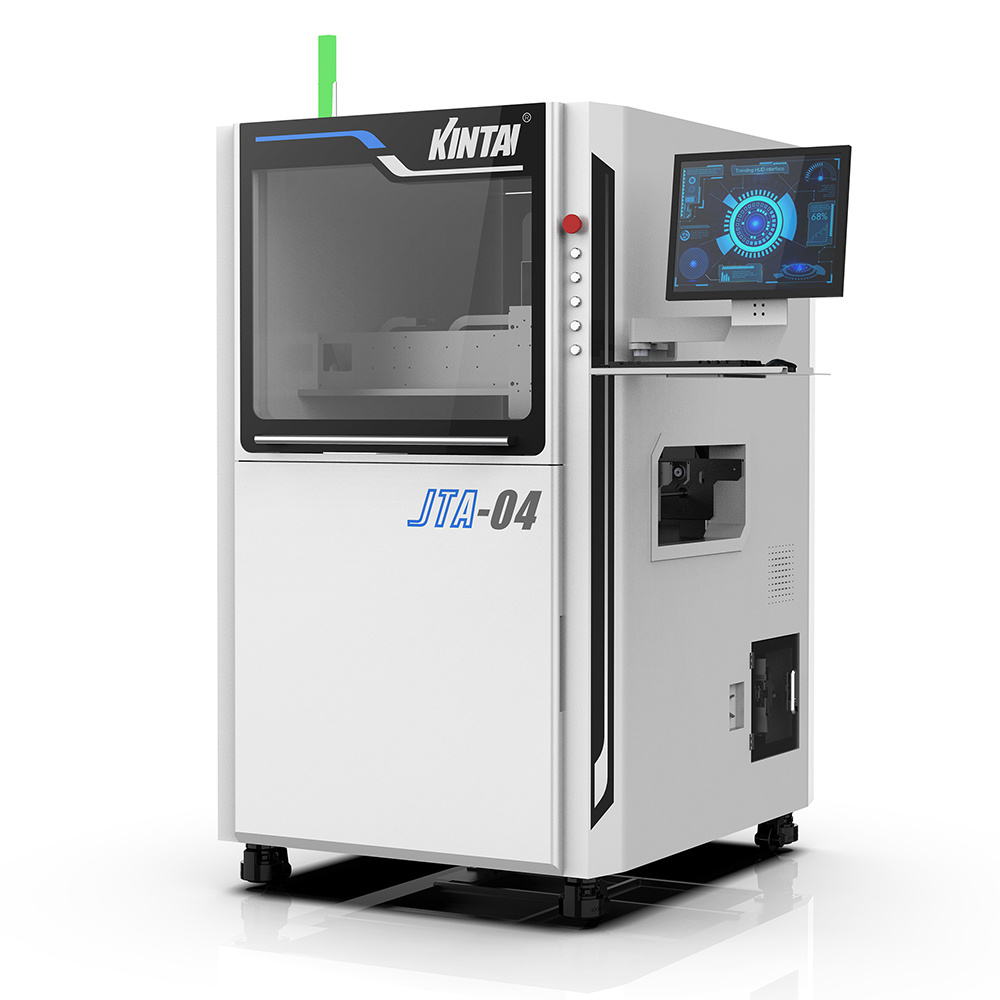

Product name : Selective coating machine automatic for PCB

Model No. :JTA-009

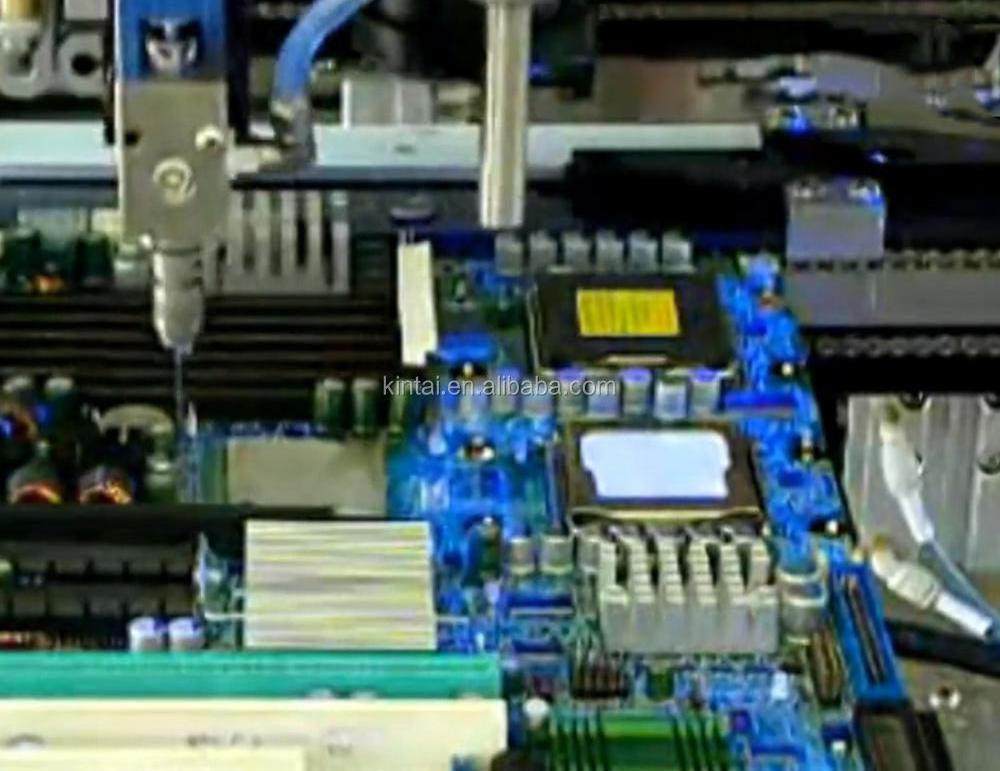

The JTA-009 Series is ideal for selective conformal coating and dispensing applications that require a high level of accuracy and repeatability in moderate to high volume manufacturing environments. It is a closed-loop robotic platform featuring optical encoder feedback on all axes.

The JTA-009 Series features a robust overhead three-axis motion platform suitable for inline or batch operations. While maintaining the preferred features of previous workcells, the JTA-009 has been designed with a slimmer footprint, improved structural and gantry rigidity for robustness, and easier access.

Key features and benefits:

- General machine comes with 2 nozzles

- PC with LCD monitors, keyboard and mouse (Height Adjustable)

- Auto dipping and purging waste collection system

- LED UV lamps for inspection

- PCB clamping system

- 10L material tank

- USB communication port

- CE Certified

Optional features:

- Dual Lane conveyor system

- CCD vision camera

- 4 direction 35º tilt

- 2 nozzles simultaneous coating + tilt

- Closed-loop material flow monitoring

- Inline material metering

- Substrate heating-contact or non-contact

- Barcode or 2D code scanning system

- Material tank : 5L

|

Dimension ( LXWXH)&Weight |

|

In-line |

|

Weight |

800kg |

|

Features |

|

|

Head Structure |

Single head 2 nozzles |

No. of Axis |

3 axis = X,Y,Z |

Drive |

Servo motors precision ball screw slides |

X,Y travelling speed |

min: 1mm/s, max: 700mm/s |

Recommended Working Speed |

5-200mm/s |

Positioning accuracy |

40μm |

Tilt Angle |

35°(Fixed) |

Work area ( based on 1 nozzle on right side) |

|

coating area |

LXW ( 460mm x 460mm) |

Z axis movement |

100mm |

Conveyor system |

|

conveyor type |

Flat belt or chain |

Board clearance |

top = 80mm, bottom = 80mm |

PCB Edge Clearance |

5mm ( pallet) / 3 mm (PCB) |

Conveyor Height |

900+/-20mm |

Conveyor speed |

Up to 750mm/min |

Flow Direction |

L->R( Option :R->L) |

Width Adjustment |

50-460mm(motorized) |

Comm. Port |

Standard SMEMA |

Facilities Requirements |

|

Power |

AC220-240v, 50-60HZ |

|

Total Power |

2.6KW |

Exhaust Flow Rate |

15 m 3 /h |

Compress Air Requirement |

0.5 Mpa, 100L/min |

Packaging & Shipping

Packaging: Strong woodend case, 1 set/ case

Delivery: about 5-7 days after down payment

Our Services

1. English User manual or operation video are provided

2.24 hours technical support by email or calling.

3.Warranty: 1 year free for spare parts, free technical support always

4.Free training to make sure user know how to use the machine well

5. OEM/ODM accept .

Hot Searches