- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FTL-PCB200

-

Power:

-

66

-

Material:

-

bags or customer required

-

Marketing Type:

-

discount

-

Weight (KG):

-

9800 kg

-

Keywords:

-

Circuit Board Recycling plant

-

Function:

-

Waste pcb recycling

-

Name:

-

E-waste Recycling plant

-

Raw material:

-

Waste circuit boards, TV boards,PCB

-

Final product:

-

Resin Power,Trace copper power

-

Application field:

-

Waste Recycling Plant Sorting

-

design Capacity:

-

200/300/500/800/1000Kg per hour

Quick Details

-

Production Capacity:

-

200-1000Kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Model Number:

-

FTL-PCB200

-

Power:

-

66

-

Material:

-

bags or customer required

-

Marketing Type:

-

discount

-

Weight (KG):

-

9800 kg

-

Keywords:

-

Circuit Board Recycling plant

-

Function:

-

Waste pcb recycling

-

Name:

-

E-waste Recycling plant

-

Raw material:

-

Waste circuit boards, TV boards,PCB

-

Final product:

-

Resin Power,Trace copper power

-

Application field:

-

Waste Recycling Plant Sorting

-

design Capacity:

-

200/300/500/800/1000Kg per hour

waste Circuit Board plant

Circuit board crushing and recycling equipment

Production capacity: 200-1000kg/h;

Scope of application: all kinds of waste circuit boards, circuit boards, copper clad plates, scraps, etc.

Product introduction: This production line adopts secondary crushing for the reproduction and processing of waste circuit boards to make them separate from metal and nonmetal. The separation purity of the circuit board recovery equipment of the whole machine reaches more than 99.5%.

At present, with the rapid development of science and technology and the increasing number of electronic waste, more than 50 million tons of waste circuit boards and scraps have been eliminated every year in China. The circuit board contains many rare metals such as copper. Non-metallics include epoxy resin, phenolic resin, curing agent, glass fiber, etc. After a long time of investigation, research and experiment, we have developed relatively ideal treatment equipment and recycling processing technology, which have been applied in many regions at home and abroad. Through independent research and development, FTL cites Germany's new gravity separation technology, and the recovery effect of the whole set of circuit boards reaches more than 99.5%

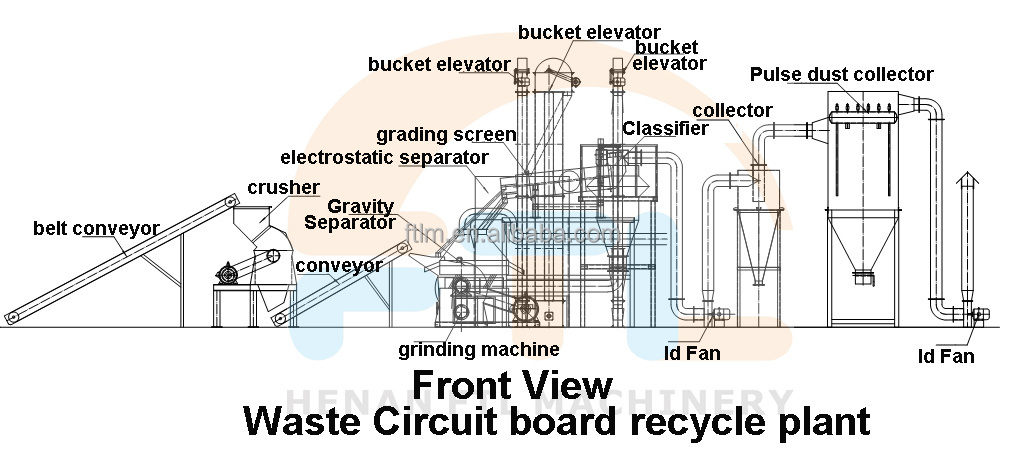

1, Introduction to electrical (wire) board recycling equipment:

The waste circuit board crushing and recycling production line is mainly used to separate metal and non-metal in waste circuit boards, copper clad boards, circuit boards and scrap materials. The successful development of this machine not only improves the quality of recovered copper, but also prevents secondary pollution. The production line adopts secondary crushing to regenerate and process the waste circuit board to make it a mixture of metal and resin fiber powder; Then the metal and resin are separated by wind and electrostatic separation. In order to prevent dust pollution in the process of processing, a pulse dust removal device is added after the air separation process, which effectively solves the problem of dust pollution.

Advantages of FTL Factory waste Circuit Board plant

1. A new process of mechanical crushing and high-voltage electrostatic separation is adopted by circuit board crusher. After disassembly, crushing and dissociation, metal and non-metal materials are separated with high purity. The separation purity of the circuit board recovery equipment of the whole machine is more than 99.5%.

2. The key technology is to organically combine the special crushing and dissociation equipment of various waste circuit boards to achieve greater energy-saving effect in the production process and achieve a high metal separation rate.

3. The unit energy consumption of circuit board recycling equipment for treating waste circuit boards per ton is only about 3/5 of that of similar domestic products; Each set of equipment has a capacity of 1 ton per hour.

4. The price of circuit board recycling equipment is only 1/5-1/3 of that of similar equipment at home and abroad, and the copper recovery rate is 3% - 5% higher than that of similar manufacturers.

5. With good comprehensive performance, it has unique effects on computer boards, computer boards, television boards and other circuit control boards. The recovery of various circuit boards containing capacitive devices is also compatible.

6. The production line of circuit board recycling equipment is an upgraded product of wind-selected products, which consumes less power than wind-selected products, has no noise, less labor, high automation procedures, high efficiency, and small floor area. It is an ideal production line for recycling waste circuit boards at present.

7. Less labor, no noise, flexible placement of circuit board recycling equipment.

1. Shredder: shred the light plate to 2-3 cm.

2. Circuit board crusher: crush the broken circuit board to about 20 meshes.

3. Analyzer: the crushed material is selected by air, and the resin, copper, dust and fiber are separated. The dust and fiber are sucked into the collector by the induced draft fan, and the resin and copper enter the grading screen.

4. Collector: collect dust and fiber, and discharge the collected fiber.

5. Pulse purifier: collect the dust and superfine fiber generated in the crushing process.

6. Grading screen: screen the resin and copper, return the undivided resin and copper to the main machine for crushing, and enter the separated resin and copper into the specific gravity separator for sorting.

7. Specific gravity separation: the resin powder and copper are separated by specific gravity. Since the weight of copper is greater than the weight of resin, the copper will be separated to one side and the resin will be separated to the other side. In this way, metal and nonmetal are separated. This is a relatively advanced technology in China at present, which can achieve more than 99% metal separation effect.

8. High-voltage electrostatic separation: the tailings passing through the specific gravity separator are subject to high-voltage electrostatic separation to separate the small copper powder and resin contained in the tailings (the principle of high-voltage electrostatic separation is to adjust the input power supply to a high voltage of 100000 volts through a transformer to form a high-voltage magnetic field, which has an adsorption effect on the conductive metal, thus achieving the separation of metal and non-metal)

Configuration of PCB recycling and processing equipment with an output of 500 kg per hour

|

Name/item |

Type |

Power |

Quantity |

Dimension |

|

Grinding machine |

FTL-700 |

55KW |

1set |

2*2*1.7m |

|

Classifier |

FTL-800 |

1.1KW |

1set |

1.2*1.2*4m |

|

cyclone feeder |

FTL-800 |

|

1set |

1*1*4m |

|

Four-stage cyclone feeder |

FTL-1600 |

|

1set |

1.8*1.6*4m |

|

3 in 1 duct collector |

FTL-1500 |

|

1set |

1.5*1.5*5.5m |

|

Bucket elevator |

FTL-180 |

1.1KW |

3sets |

0.6*0.6*5.5m |

|

Grading machine |

FTL-1000 |

0.37KW |

1set |

3*1.5*3.5m |

|

electrostatic separator |

FTL-1000-2 |

1.1+2.2KW |

2sets |

2*1.8*2.3 |

|

Capacity |

500-600kg/h |

|||

|

Total power |

66KW |

|||

|

Total space |

95m2 |

|||

Configuration of PCB recycling and processing equipment with an output of 1000 kg per hour

|

Name/item |

Type |

Power |

Quantity |

Dimension |

|

Double roll crusher |

FTL-600 |

22KW |

1 set |

1.8*1.8*2m |

|

Hammer crusher |

FTL -400 |

18.5+3KW |

1 set |

|

|

Mine bucket elevator |

FTL -220 |

2.2KW |

1 set |

0.8*0.8*5.5m |

|

hopper |

FTL -1000*3000 |

|

1 set |

3*1.2*4m |

|

conveyor |

FTL -600*4m |

1.1KW |

2 sets |

4*1*2m |

|

Grinding machine |

FTL -700 |

55KW |

2 sets |

2*2*1.7m |

|

Classifier |

FTL -800 |

1.1KW |

2 sets |

1.2*1.2*4m |

|

cyclone feeder |

FTL -800 |

|

2 sets |

1*1*4m |

|

Four-stage cyclone feeder |

FTL -1600 |

|

2 sets |

1.8*1.6*4m |

|

3 in 1 duct collector |

FTL -1500 |

|

2 sets |

1.5*1.5*5.5m |

|

Bucket elevator |

FTL -180 |

1.1KW |

6 sets |

0.6*0.6*5.5m |

|

Grading machine |

FTL -1000 |

0.37KW |

2 sets |

3*1.5*3.5m |

|

electrostatic separator |

FTL -1000-2 |

1.1+2.2KW |

4 sets |

2*1.8*2.3 |

|

Capacity |

1000-1500kg/h |

|||

|

Total power |

172KW |

|||

|

Total space |

200m2 |

|||

Circuit board crushing and recycling equipment At Site:

FTL factory specialize in recycle machine and production line, Main products: circuit board crushing and recycling equipment, circuit board dismantling equipment, circuit board gold extraction equipment, home appliance dismantling equipment, waste capacitor crushing and recycling equipment, lithium battery crushing and recycling equipment, lithium battery positive and negative pole recycling equipment, soft bag battery processing and recycling equipment, aluminum plastic separation and recycling equipment, aluminum plastic crusher.