- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

depends on the model

-

Weight:

-

5200 KG

-

Product name:

-

Coal Washing Plant For Sale

-

Keywords:

-

Coal Process Production Line

-

Certification:

-

ISO CE

-

Color:

-

Customers' Requirements

-

Capacity:

-

1-300TPH

-

Price:

-

Negotiable

-

Quality:

-

High Level

-

Feature:

-

High Recovery Rate Easy

-

Advantage:

-

High Separation Efficiency

-

After-sales Service:

-

Provided

Quick Details

-

Production Capacity:

-

1-500tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

depends on the model

-

Weight:

-

5200 KG

-

Product name:

-

Coal Washing Plant For Sale

-

Keywords:

-

Coal Process Production Line

-

Certification:

-

ISO CE

-

Color:

-

Customers' Requirements

-

Capacity:

-

1-300TPH

-

Price:

-

Negotiable

-

Quality:

-

High Level

-

Feature:

-

High Recovery Rate Easy

-

Advantage:

-

High Separation Efficiency

-

After-sales Service:

-

Provided

Product Description

Overview

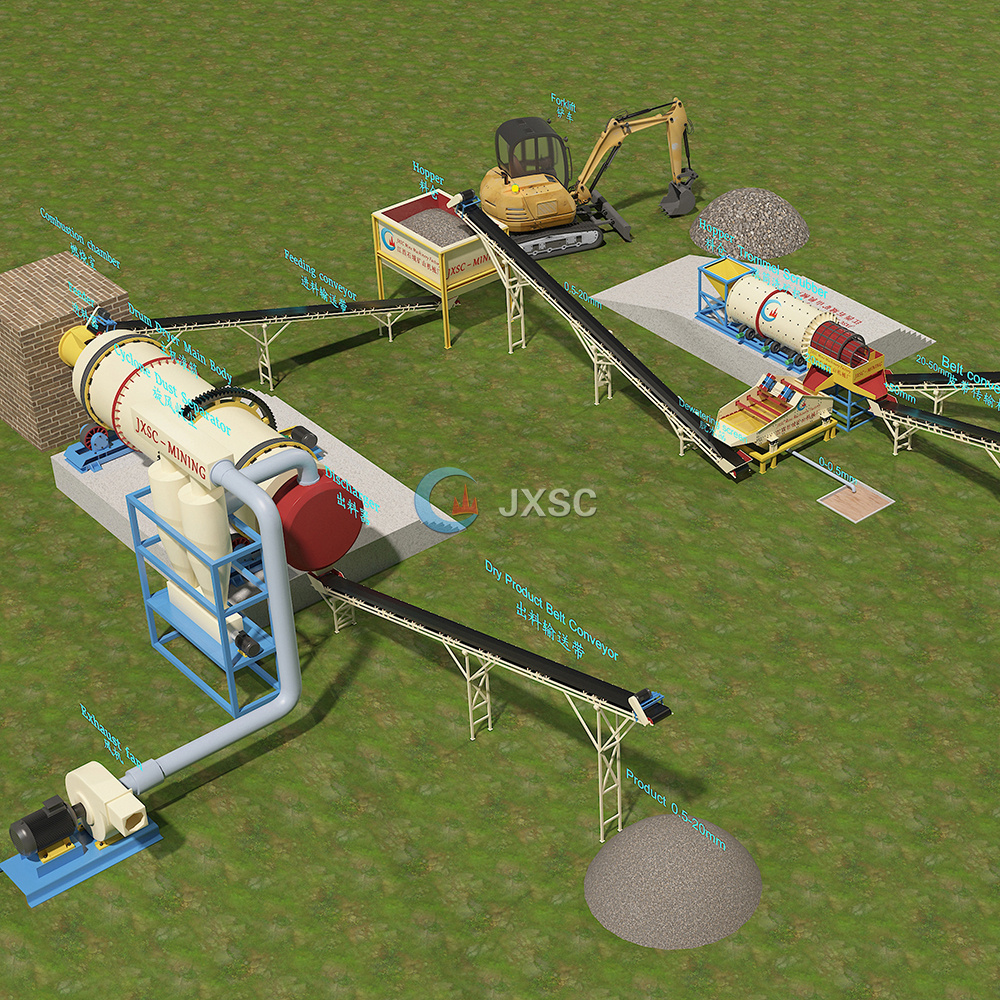

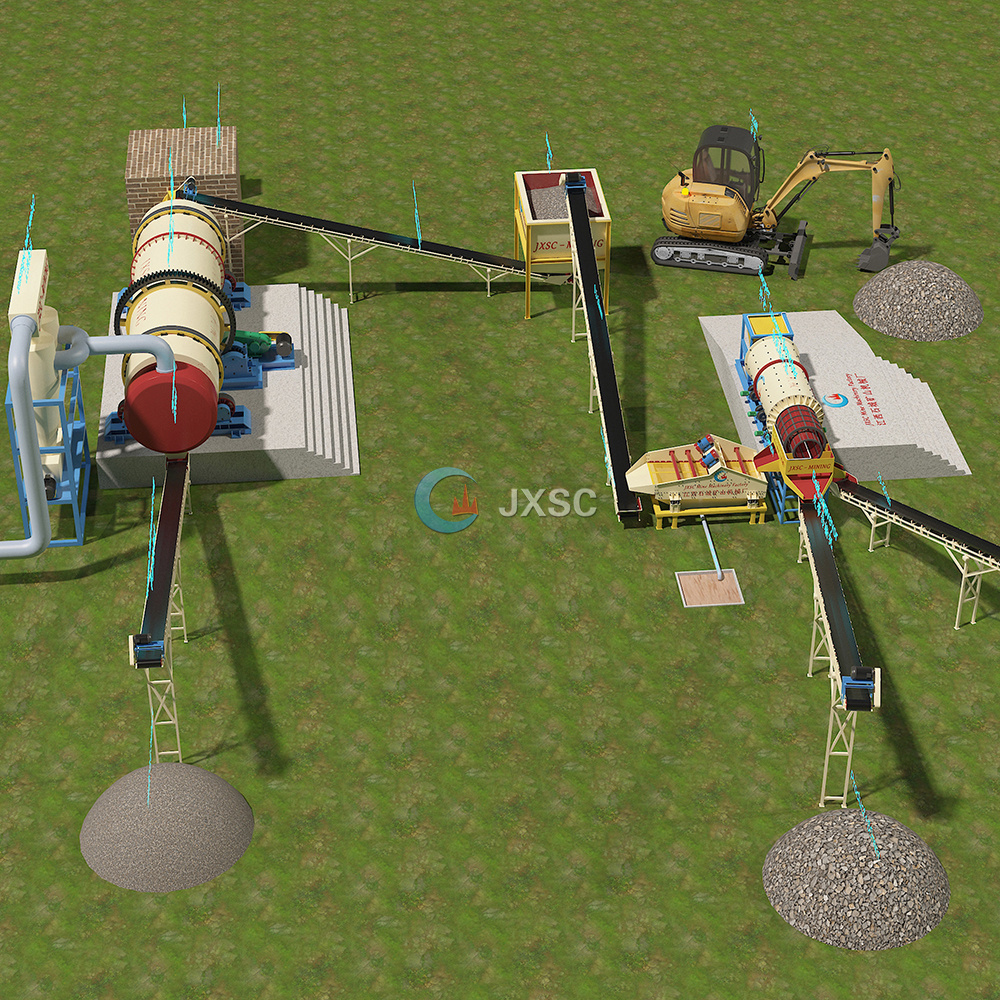

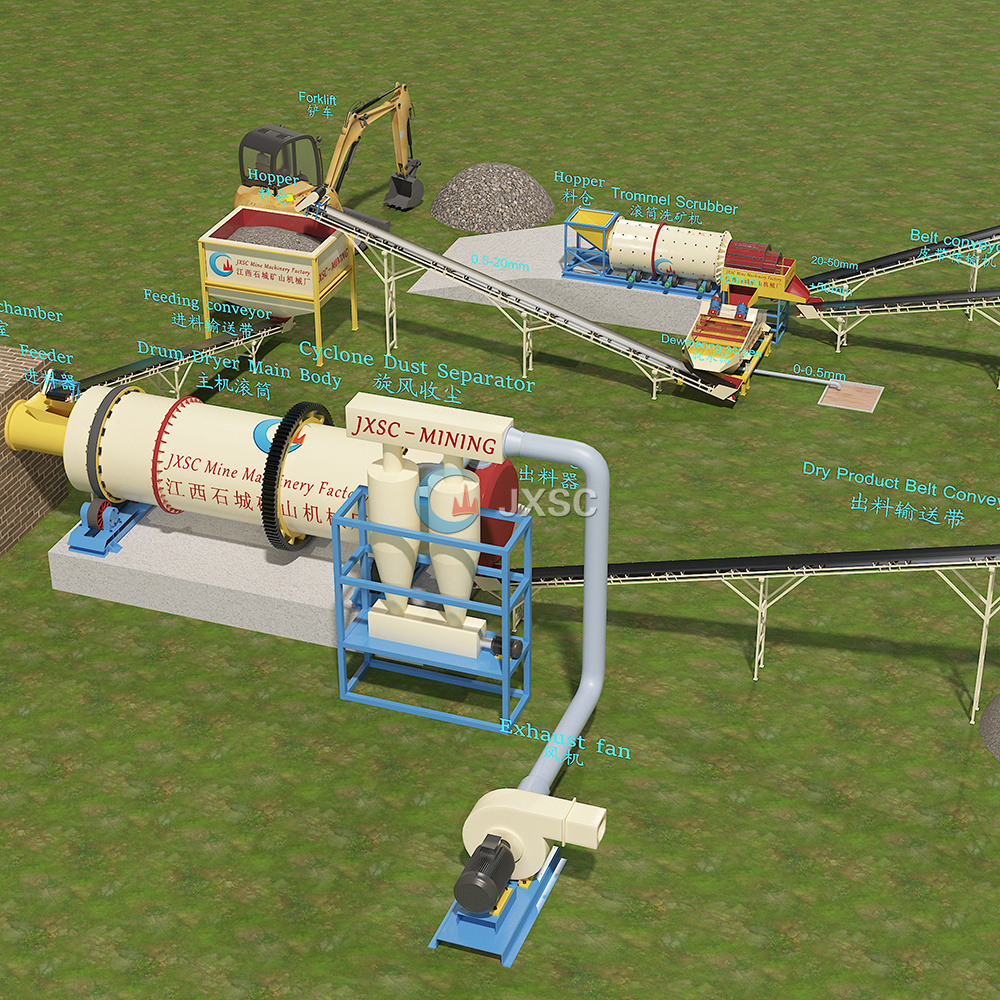

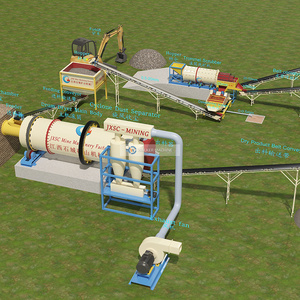

Coal Washing Plant

1. Coal, contain with clay

2. Feeding size 0-150mm

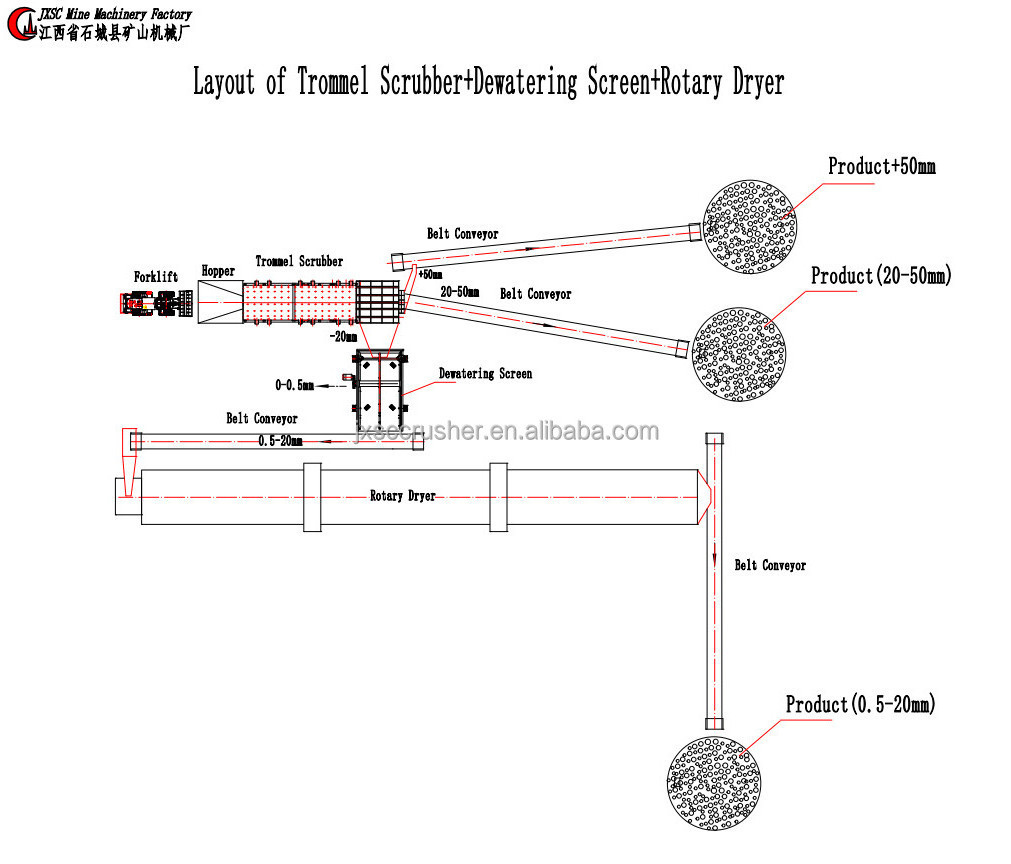

Highlights of this coal wash processing plant

1. Coal Ore washing

2. Trommel Scrubber screening and separating coal ores, and get

3 different sizes output.

3 different sizes output.

4. Using Rotary Dryer to get dry coal products

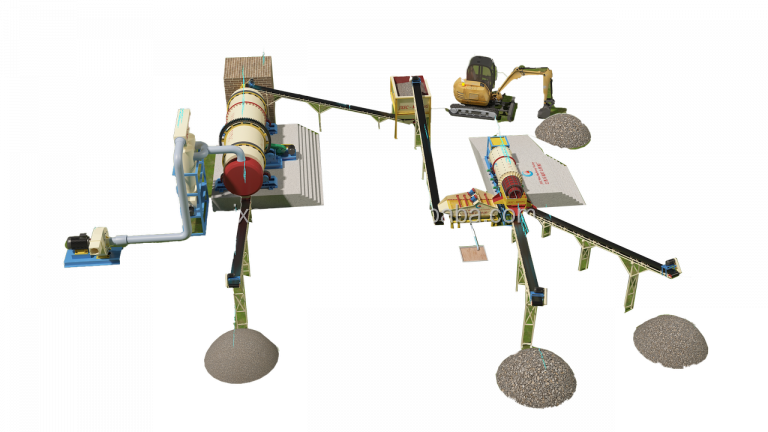

Customer’s requirements:

Customer’s requirements:

1. Washing

2. Screen for 3 outputs

3. Rotary dryer for drying coal

Screen output:

1. Above 50mm

2.20-50mm

3. Below 20mm

Processing Flow Overview▼

Processing Flow Overview▼

2. Below 20mm go to the dewatering screen by gravity flow. Here put the dewatering screen lower level than the trommel scrubber, so that 0-20mm slurry can flow to the dewatering screen by height difference.

3. Over screen materials of dewatering screen are sent to rotary dryer system for drying coal by feeding conveyor.

4. The finished product after drying is transported by discharging conveyor.

Main Product

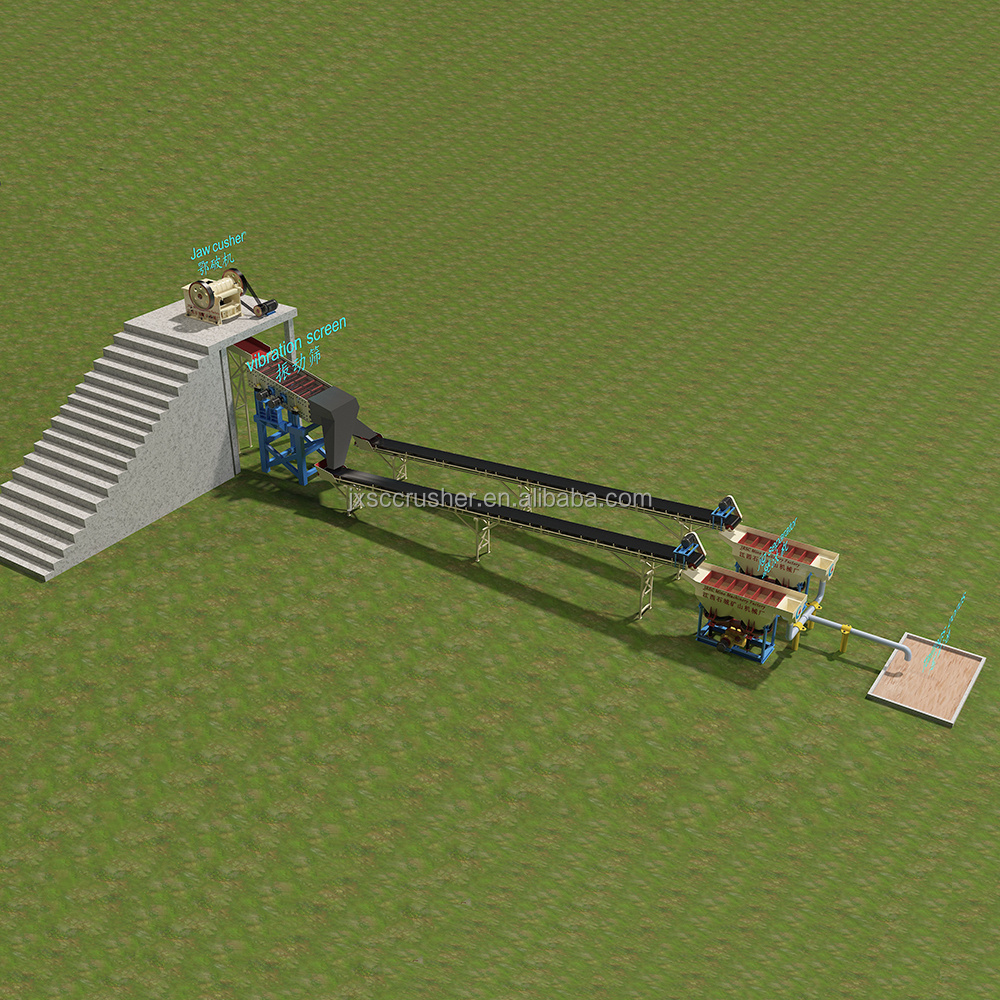

We have professional engineers team to draw flowchart based on customer's coal ore site details. We supplied full set coal wash processing plant: Trommel Scrubber, Vibrating Screen, Rotary Dryer, Slurry Pump

Successful Cases

10TPH Coal Process Plant in Mexico

Packaging & Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the

container.

container.

● Shiping by sea/air freight

or any way the customer requires.

or any way the customer requires.

Company Introduction

JXSC Mining Equipment Manufacturer is an experienced supplier of Gold Mining Equipment including gold wash plant, stone crusher machine, gravity concentration, magnetic separation, feeder equipment, mining laboratory equipment. Our Gold Wash Plant is widely used for gold mining plant among home and abroad, whole alluvial gold production line and gold mining equipment, diamond mining equipment, silica sand mining own a good name in the international market, owing to advanced design compare to top brands like MSI MINING.

Trusted mining equipment manufacturers leader in mineral processing technologies,ISO9001: 2008 and CE certified,providing high quality manufacturing,engineering support & professional mining design since establishing in China in 1985.

JXSC mine machinery factory, is specializing in manufacturing, and uniquely provides complete range of mining equipment, mining accessories for either placer or hard rock mineral types,also,processing and recovery of various metals and minerals: Precious Metals, Precious and Semi-Precious Stones, Base Metals, Ferrous and Non-Ferrous Metals, Noble Metals, Heavy Metals.

7*24 hours online consulting service, we provide you with the prophase plan, process flow design and

manufacturer equipment according to your special demand.

Send technicians to the job site guiding the installation and adjustment, training operators and finishing the check and accept together with you.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our

products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require? Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches