- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

550mm

-

Dimension(L*W*H):

-

2800*2360*2400mm

-

Weight (T):

-

5.8 T

-

Table Travel (Z) (mm):

-

550mm

-

Positioning Accuracy (mm):

-

±0.005/300mm

-

Repeatability (X/Y/Z) (mm):

-

±0.003mm

-

Range of Spindle Speed(r.p.m):

-

80 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5Kw

-

Max. Table Load(kg):

-

600 kg

-

Feed Speed(mm/min):

-

1 - 8000 mm/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shandong Yijin CNC

-

X-axis rapid movement:

-

36m/min

-

y-axis rapid movement:

-

36m/min

-

z-axis rapid movement:

-

36m/min

Quick Details

-

Table Size (mm):

-

1000*550mm

-

Number of Axes:

-

3

-

Table Travel (X) (mm):

-

800mm

-

Table Travel (Y) (mm):

-

550mm

-

Dimension(L*W*H):

-

2800*2360*2400mm

-

Weight (T):

-

5.8 T

-

Table Travel (Z) (mm):

-

550mm

-

Positioning Accuracy (mm):

-

±0.005/300mm

-

Repeatability (X/Y/Z) (mm):

-

±0.003mm

-

Range of Spindle Speed(r.p.m):

-

80 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5Kw

-

Max. Table Load(kg):

-

600 kg

-

Feed Speed(mm/min):

-

1 - 8000 mm/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shandong Yijin CNC

-

X-axis rapid movement:

-

36m/min

-

y-axis rapid movement:

-

36m/min

-

z-axis rapid movement:

-

36m/min

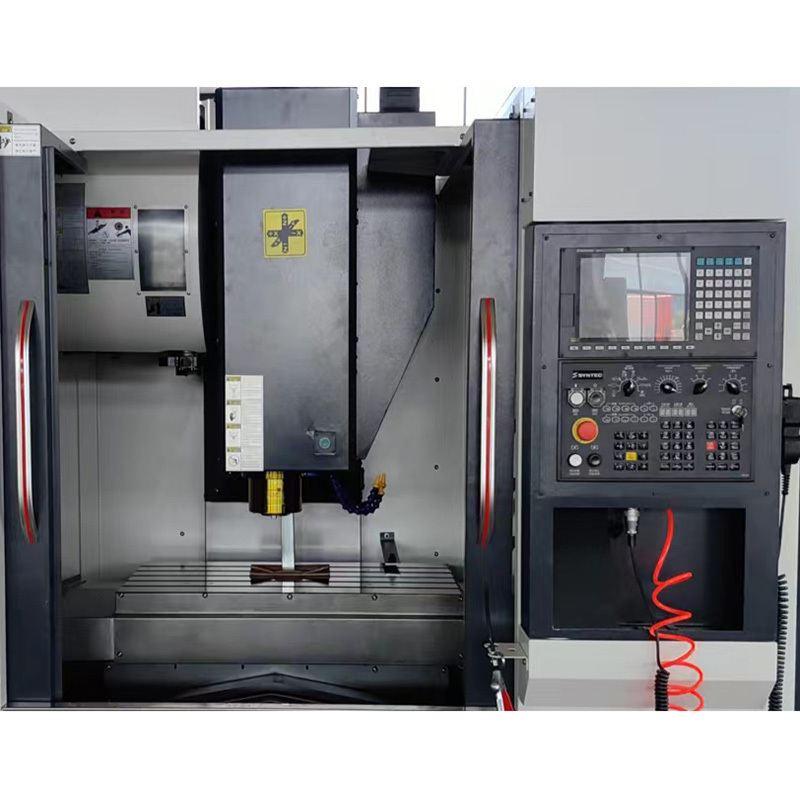

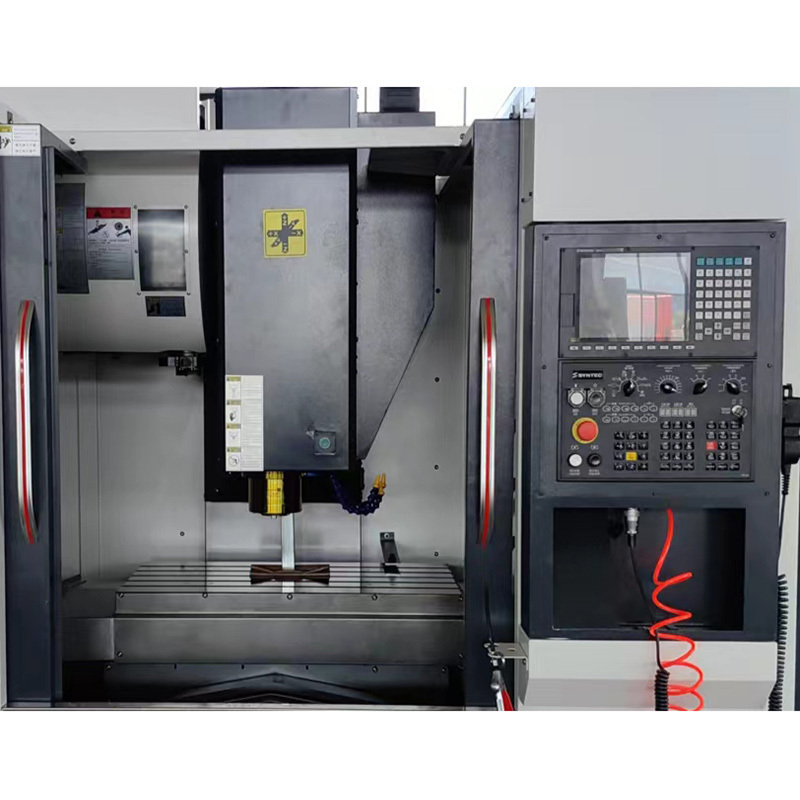

Product Overview

VMC855lathe

The feed axis of the machining center is controlled by X, Y, and Z coordinates, and the spindle is driven by servo motor power. The tool magazine has a capacity of 24 disc type tool magazines. It can achieve one-time clamping of complex parts such as various discs, plates, shells, cams, molds, etc., and complete various processes such as drilling, milling, boring, expanding, hinging, tapping, etc. It is suitable for the production of multiple varieties, small and medium-sized batch products, and can demonstrate its superiority in the processing of complex and high-precision parts.

PRODUCT SPECIFICATIONS

|

parameter

|

|

VMC855

|

|

|

trip

|

x-axis

|

800mm

|

|

|

|

y-axis

|

550mm

|

|

|

|

z-axis

|

550mm

|

|

|

|

Spindle end face to workbench

|

120-670mm

|

|

|

|

Spindle center to column guide rail

|

540mm

|

|

|

feed

|

X-axis rapid movement

|

36m/min

|

|

|

|

y-axis rapid movement

|

36m/min

|

|

|

|

z-axis rapid movement

|

36m/min

|

|

|

|

Cutting feed

|

1-8000mm/min

|

|

|

staging

|

Table size

|

1000×550mm

|

|

|

|

Max load

|

600kg

|

|

|

|

t-slot

|

5-18-90mm

|

|

|

main shaft

|

speed

|

8000rpm

|

|

|

|

Spindle diameter

|

150mm

|

|

|

|

Spindle taper hole

|

BT40

|

|

|

|

Main motor power

|

7.5Kw

|

|

|

|

Transmission mode

|

Belt Type

|

|

|

magazine

|

specifications

|

24T

|

|

|

|

types of

|

disc type

|

|

|

Machine tool specifications

|

weight

|

5800 Kg

|

|

|

|

Overall dimensions

|

2800×2360×2400mm

|

|

|

|

positioning accuracy

|

±0.005/300mm

|

|

|

|

repeatability

|

±0.003mm

|

|

Product Details

cnc

The system has complete and reliable interlocking, safety protection, fault diagnosis and alarm functions, and is equipped with RS232 standard communication interface. It can be programmed and stored with a computer, and can achieve DNC processing.

Detailed configuration

1. Spindle unit, up to 8000rpm;

2. CNC system KND2000, spindle motor 7.5Kw;

3. Automatic release knife, pneumatic cutting mechanism;

4. Automatic centralized forced oil lubrication for screw and guide rails;

5. High pressure water cooling;

6. Air cooling;

7. Fully protective sheet metal cover;

8. 24 disc type tool libraries;

9. Mobile hand operated pulse generator;

10. RS232 interface;

11. Three color alarm light;

Factory Realistic View

We are a set of professional design, manufacturing and sales, CNC machine tool of modern enterprises, the company is located in China's machine tool capital, Mozi hometown __ Tengzhou city. It is a high-tech enterprise in Shandong Province and a key software enterprise in Shandong Province. With a large number of rich design solutions can quickly respond to customer requirements to provide technical solutions.

SIMILAR PRODUCTS

1. Vertical machining center machine.

2. The three axis guide rails are all Taiwan Shangyin linear guide rails.

3. Three axis grinding ball screw, directly connected to servo motor.

4. Taiwan brand spindle unit with a rotational speed of 8000rpm.

5. Fully protected waterproof sheet metal.

6. The spindle motor drives the spindle through a synchronous belt, with servo stepless speed regulation and rigid tapping.

7. X, Y, Z three axis linkage.

8. Cooperate with customers to purchase machine tools according to their product needs.

9. Coordinate machine tool debugging with product processing specimens and programming.

Passed GB/T 19001-2008 idt ISO9001:2008 Quality System Certification

The machine tool design complies with ISO international standards and relevant national standards

All components of the machine tool and various instruments are measured in national standards

Quality and inspection standards

The accuracy inspection shall be carried out in accordance with the standard JB/T8329.1-1999 "Accuracy Inspection of CNC Bed Milling Machines"

1. Strictly control the quality of raw material procurement and prevent unqualified materials from entering the factory.

2. Machine tool manufacturing strictly follows the quality management system certification to ensure the qualification and quality of each processed product.

3. Strictly inspect the accuracy, noise, and electrical components of the machine tool before leaving the factory to ensure that each machine is a high-quality product.

Related certificates

ce certificate

The company has CE certification and is specialized in the mechanical industry, with its own independent factory,

We have excellent process equipment for pre delivery inspection,

For many years, we have been committed to manufacturing and exporting machine tools to the world. Our factory continuously develops and produces innovative high-tech machine tools for the metal processing industry every year. We also provide excellent after-sales service to all customers worldwide.

Company Exhibition

Exhibition

The company actively participates in various exhibitions, communicates and exchanges with customers, and directly showcases its

FAQ

Q1:

Are you the manufacture?Can we visit your factory?

A1:We are manufacturer and we are located in Shandong,China.And we have our own design team for products design.

And welcome you visit our factory and check our machine qualtiy on spot,any question will be solved on spot at first time.

And welcome you visit our factory and check our machine qualtiy on spot,any question will be solved on spot at first time.

Q2:How to control the quality of the products?

A2:We have always placed great emphasis on the quality level is maintained. Moreover, the principle we always maintain is "toprovide customers better quality, better price, and better service".

Q3:And are you able to update the production process Information in time after placing our order?

A3:

After confirming your order ,

we would keep you updated of production details of emails and photos

.

Hot Searches