- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

xingdou machinery

-

Voltage:

-

110V,220V,380V,410V...

-

Dimension(L*W*H):

-

as per order

-

Weight:

-

200 KG

-

Product name:

-

Ultrasonic Vibrating Screen

-

Motor:

-

Vibrating Motor

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Function:

-

Screening\separation\sorting\sieving

-

Capacity:

-

100Kg-10Tons/hour

-

Layer(s):

-

1-4 Layers

-

Feature:

-

High Screening Efficiency

-

Mesh size:

-

2~500 Mesh

-

Cleaning system:

-

Bouncing Ball Cleaning System

-

Diameter:

-

400~1500mm

Quick Details

-

Type:

-

Circular

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

China

-

Brand Name:

-

xingdou machinery

-

Voltage:

-

110V,220V,380V,410V...

-

Dimension(L*W*H):

-

as per order

-

Weight:

-

200 KG

-

Product name:

-

Ultrasonic Vibrating Screen

-

Motor:

-

Vibrating Motor

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Function:

-

Screening\separation\sorting\sieving

-

Capacity:

-

100Kg-10Tons/hour

-

Layer(s):

-

1-4 Layers

-

Feature:

-

High Screening Efficiency

-

Mesh size:

-

2~500 Mesh

-

Cleaning system:

-

Bouncing Ball Cleaning System

-

Diameter:

-

400~1500mm

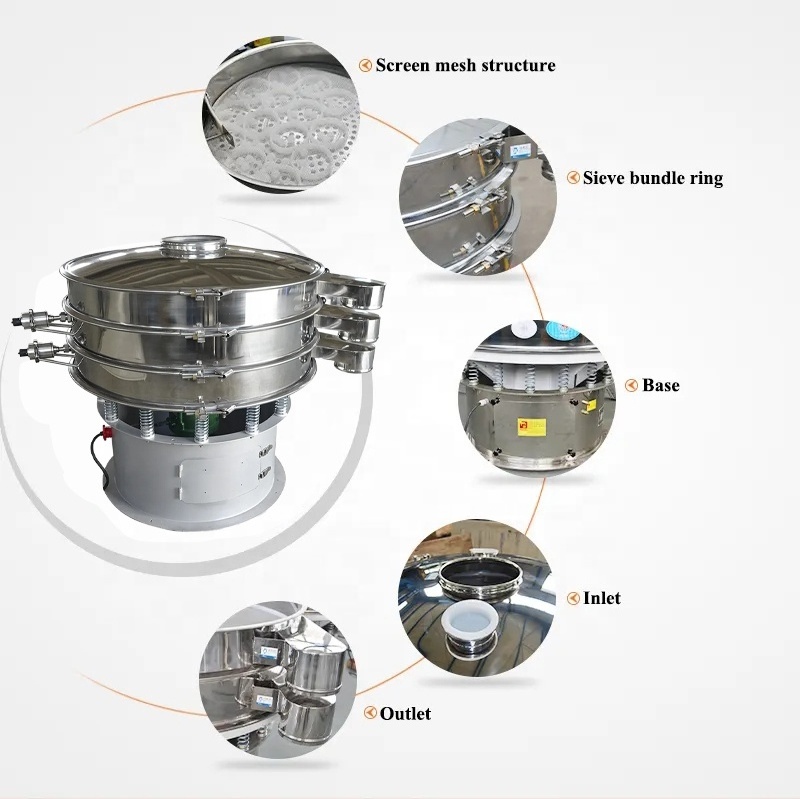

Products Description

Rotary vibrating screen is a type of vibrating screen that separates materials by size using a rotating motion. This motion is typically generated by a motor that causes the screen to rotate in a circular motion, allowing particles to pass through the screen and be separated based on size. The rotary vibrating screen is commonly used in industries such as food processing, pharmaceuticals, chemicals, minerals, and many others. It is an efficient and cost-effective method for sorting and separating particles of different sizes. The benefits of using a rotary vibrating screen include high efficiency, continuous operation, low noise levels, and easy maintenance. It can be customized to meet specific material requirements and is capable of separating particles ranging from very fine to coarse.

|

Model of rotary vibrating screen

|

Motor type

|

Motor model

|

Motor power

|

voltage

|

motor speed

|

Equipment material

|

number of plies

|

|

XD-400

|

Vertical vibration motor

|

YZUL3-4

|

0.25KW

|

220-480V industrial three-phase power

|

1500r/min

|

Q235/304/316L

|

1-2 floors

|

|

XD-600

|

Vertical vibration motor

|

YZUL5-4

|

0.55KW

|

220-480V industrial three-phase power

|

1500r/min

|

Q235/304/316L

|

1-4 floors

|

|

XD-800

|

Vertical vibration motor

|

YZUL8-4

|

0.75KW

|

220-480V industrial three-phase power

|

1500r/min

|

Q235/304/316L

|

1-4 floors

|

|

XD-1000

|

Vertical vibration motor

|

YZUL10-4

|

1.1KW

|

220-480V industrial three-phase power

|

1500r/min

|

Q235/304/316L

|

1-4 floors

|

|

XD-1200

|

Vertical vibration motor

|

YZUL15-4

|

1.5KW

|

220-480V industrial three-phase power

|

1500r/min

|

Q235/304/316L

|

1-4 floors

|

|

XD-1500

|

Vertical vibration motor

|

YZUL30-4

|

2.2KW

|

220-480V industrial three-phase power

|

1500r/min

|

Q235/304/316L

|

1-4 floors

|

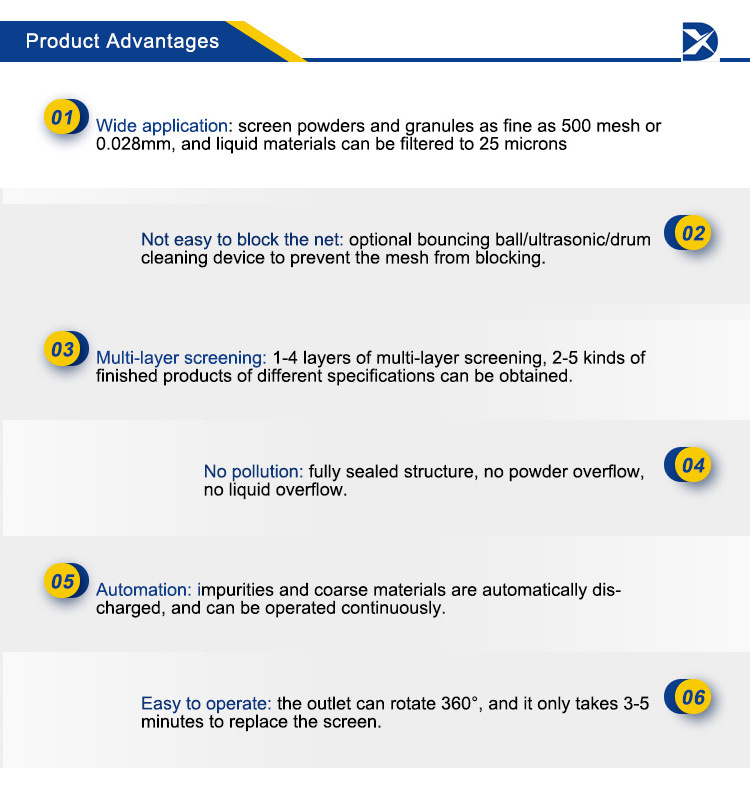

Product Advantages

Working Principle

Our Advantages

After Sales Service Terms:

1: If technical support is required, the solution should be provided within 1 hour during working hours. During non working hours, respond within 12 hours and provide me with a solution.

2: For parts that need to be repaired or replaced: During the warranty period, our company will bear all the costs, while outside the warranty period, we will charge a basic fee.

3: Our company has inventory of all conventional accessories used, and generally ships them within two days after confirming the problem

4: The technical support used for our equipment is free for life.

You can directly contact your sales manager or add Whatsapp +

8618603739862

or WeChat

8618603739862

Good reviews from users

FAQ

Tell me the following questions, then I can send you an accurate quotation soon, including additional discount! Your email

addressand telephone will not be shared or published!

The proper selection of the 210 Micron Vibrating Screen Sifter Arabic Gum Powder Vibration Sieve Machine depends on therawmaterial, mesh size, required output, method of input, abrasiveness of the material, etc:

addressand telephone will not be shared or published!

The proper selection of the 210 Micron Vibrating Screen Sifter Arabic Gum Powder Vibration Sieve Machine depends on therawmaterial, mesh size, required output, method of input, abrasiveness of the material, etc:

1. Material:_____, specific

gravity/density:_____

gravity/density:_____

2. Moisture:_____%

3. Capacity:________kg/ hour

4. Screen layer:_______

5. Screen mesh size:______ mesh .

______ mesh. ______ mesh

______ mesh. ______ mesh

6. Voltage:______V, Frequency:______HZ, 3 phase

7. SS304/316L stainless steel or carbon steel?

Q: How long for the manufacturing time?

Q: How long for the manufacturing time?

A: 10-15 working days.

Q: How long for warranty time?

A: 13 months from the shipping date.

Q: How can we guarantee the quality?

A: We provide a set of the sealing parts and installation tools of vibrating screen withourmachine for free. And one year warranty period.

Q: What can you buy from us?

A: We provide one stop solution for powdermaterials: screening, conveying, weighing, mixing, packingand dumping.

Hot Searches