Q1 Are you trading company or manufacturer ?

We are factory.

Q2 How long is your delivery time?

Generally it is 15-18 days.

Q3 Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4 What is your terms of payment ?

Payment<=10000USD,100% in advance.

Payment>=10000USD,30% T/T in advance ,balance before shippment.

- Product Details

- {{item.text}}

Quick Details

-

Certificate:

-

ISO9001

Quick Details

-

Metal Type:

-

TINPLATE

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Certificate:

-

ISO9001

OUR ADVANTAGES

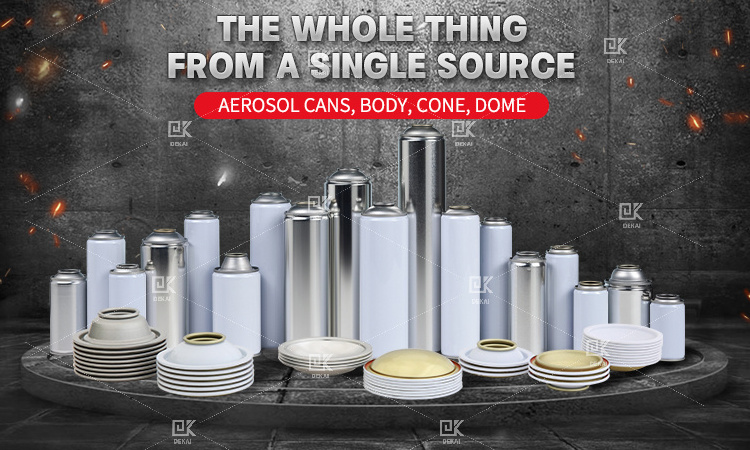

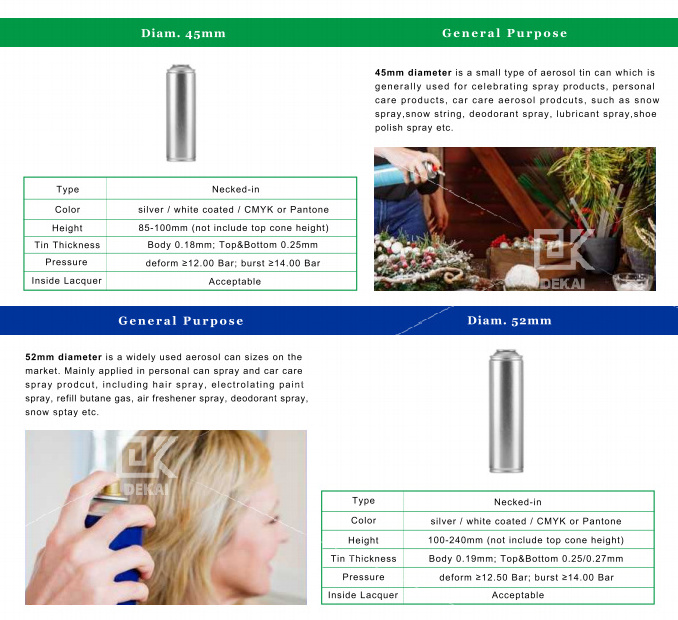

45-65mm Dia Empty Tinplate Body Spray Packaging Aerosol Can with OEM Printing Factory

|

Dia

meter

(mm) |

Type

|

Body Height

(mm) |

Buckling Pressure

(Mpa) |

Burst Pressure

(Mpa) |

Thickness

for can body

(mm)

|

Thickness

for Top

(mm)

|

Thickness

for Bottom

(mm)

|

|

φ45

|

Necked-in

|

95-200

|

1.2-1.8

|

1.4-2.0

|

0.19-2.0

|

0.28

|

0.28

|

|

φ52

|

Necked-in

|

100-300

|

1.2-1.8

|

1.4-2.0

|

0.19-2.0

|

0.28

|

0.28

|

|

φ57

|

Necked-in

|

100-300

|

1.2-1.8

|

1.4-2.0

|

0.19-2.0

|

0.28

|

0.28

|

|

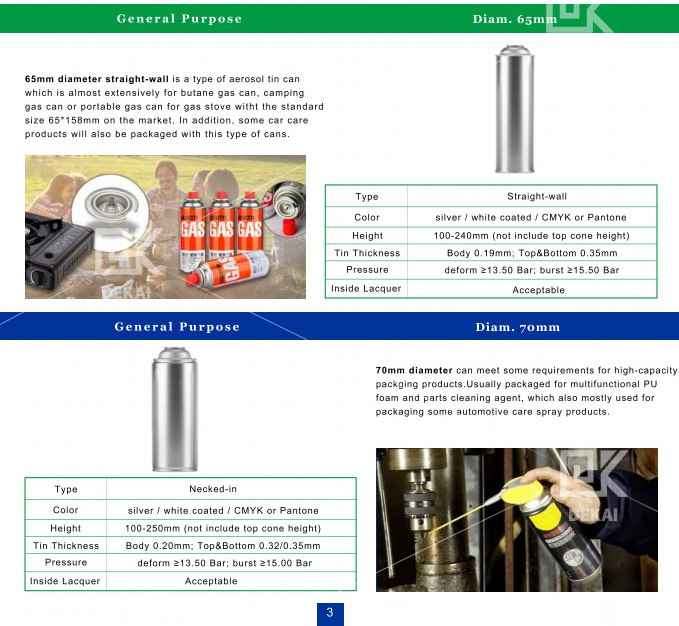

φ65

|

Necked-in

|

100-300

|

1.2

|

1.4

|

0.2-0.23

|

0.32/0.35

|

0.32/0.35

|

|

φ70

|

straight

|

100-240

|

1.2

|

1.4

|

0.2-0.23

|

0.35

|

0.35

|

|

φ70

|

Necked-in

|

100-240

|

1.2

|

1.4

|

0.2-0.23

|

0.35

|

0.35

|

|

MAIN PRODUCTS

|

20 Years+ experience in metal printing & Lacquering and Aerosol cans making.

|

DEKAI INTRODUCTION

|

Your One-Step Packaging Expert.

NOT JUST THESE...

From low to high end - choose your perfect fit with our multiple sizes and specifications.

|

Type

|

Normal Thickness

|

Normal Width

|

Normal Length

|

Weight

|

Coil Internal Diameter

|

|

Sheet

|

0.15~0.45mm

|

508~960mm

|

712~1145mm

|

1~1.5ton

|

------

|

|

Coil

|

0.15~0.45mm

|

508~960mm

|

712~1145mm

|

3~10ton

|

410/508mm

|

|

Standard

Material

|

Q/BQB

455-2009 |

JIS

G3315-2008 |

ASTM

A623M-08 |

EM

10202:1989 |

EN

1020:2001 |

ISO

11950:1995 |

|

Single Reduce

|

-

|

T-1

|

T-1(49)

|

T50

|

TS230

|

TH50+CE

|

|

|

T-1.5

|

-

|

-

|

-

|

-

|

-

|

|

|

T-2

|

T-2

|

T-2(T53)

|

T52

|

TS245

|

TH52+CE

|

|

|

T-2.5

|

T-2.5

|

-

|

-

|

TS260

|

TH55+CE

|

|

|

T-3

|

T-3

|

T-3(T57)

|

T57

|

TS275

|

TH57+CE

|

|

|

T-3.5

|

-

|

-

|

-

|

TS290

|

-

|

|

|

T-4

|

T-4

|

T-4(T61)

|

T61

|

TH415

|

TH61+CE

|

|

|

T-5

|

T-5

|

T-5(T65)

|

T65

|

TH435

|

TH65+CE

|

|

Double Reduce

|

DR-7M

|

-

|

DR-7.5

|

-

|

TH520

|

-

|

|

|

DR-8

|

LR-8

|

DR-8

|

DR550

|

TH550

|

TH550+CE

|

|

|

DR-8M

|

-

|

DR-8.5

|

-

|

TH580

|

TH580+CE

|

|

|

DR-9

|

DR-9

|

DR-9

|

DR620

|

TH620

|

TH620+CE

|

|

|

DR-9M

|

DR-9M

|

DR-9.5

|

DR-660

|

-

|

TH660+CE

|

|

|

DR-10

|

DR-10

|

-

|

-

|

-

|

TH690+CE

|

|

Tinplate Status

|

Coating Status

|

Former Coat

|

Coating W. Code

|

Normal C-W

|

Min. Ave. C-W

|

Remarks

|

|

EPT

|

Equally Coating (E)

|

10#

|

1.1/1.1

|

1.1/1.1

|

0.9/0.9

|

All specifications

|

|

|

|

20#

|

2.2/2.2

|

2.2/2.2

|

1.8/1.8

|

|

|

|

|

25#

|

2.8/2.8

|

2.8/2.8

|

2.5/2.5

|

|

|

|

|

50#

|

5.6/5.6

|

5.6/5.6

|

5.2/5.2

|

|

|

|

|

75#

|

8.4/8.4

|

8.4/8.4

|

7.8/7.8

|

|

|

|

|

100#

|

11.2/11.2

|

11.2/11.2

|

10.1/10.1

|

|

|

|

Classified Coat (D/A)

|

25#/10#

|

2.8/1.1

|

2.8/1.1

|

2.5/0.9

|

|

|

|

|

50#/10#

|

5.6/1.1

|

5.6/1.1

|

5.2/0.9

|

|

|

|

|

50#/25#

|

5.6/2.8

|

5.6/2.8

|

5.2/2.5

|

|

|

|

|

75#/25#

|

8.4/2.8

|

8.4/2.8

|

7.8/2.5

|

|

|

|

|

75#/50#

|

8.4/5.6

|

8.4/5.6

|

7.8/5.2

|

|

|

|

|

100#/25#

|

11.2/2.8

|

11.2/2.8

|

10.1/2.5

|

|

|

|

|

100#/50#

|

11.2/5.6

|

11.2/5.6

|

10.1/5.2

|

|

|

|

|

100#/75#

|

11.2/8.4

|

11.2/8.4

|

10.1/7.8

|

|

|

Single Reduce

|

B

|

Bright Surface

|

Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth.

|

|

|

R

|

Stone Surface

|

Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone

figures. |

|

|

S

|

Silver Surface

|

Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface.

|

|

|

M

|

Matte Surface

|

Matte Surface

|

|

|

R

|

Stone Surface

|

Glazed surface obtained a thin layer of chromium and chromium oxide

deposit on smooth steel base featuring certain oriented stone figures. |

Hot Searches