2 Feeding platform part 1

3 pitch shafts and leveling part 1

4 Forming system with servo motor size changeable 1

5 Transmission system 1

6 None changeable cutter 1

7 Run Out table 2

8 Hydraulic pump station 1

9 Control box 1

10 Spare parts and tools 1

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

1-3mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

DT

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

L15m*W2m*H2.2m

-

Weight:

-

15000 kg

-

Feeding width:

-

customized

-

Marketing Type:

-

Hot Product 2023

-

Thickness:

-

2mm-3mm

-

size:

-

80-150 C

-

base frame/transmission:

-

whole iron plates welded/chains

-

material:

-

Q235 carbon steel / galvanized/black strips

-

main motor + hydraulic motor power:

-

18.5 kw+ 11 kw +2.2 kw*3

-

forming station:

-

14 stations

-

forming speed:

-

20 m/min

-

shaft diameter /roller material:

-

70mm solid shafts /Gcr15 Bearing Steels with Quenching

-

electric control cabinet:

-

DELTA TOUCH SCREEN /PLC or customzied brand as clilent request

-

machine stands:

-

110 type cast iron machine stands

Quick Details

-

Type:

-

C purlin Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20 m/min

-

Rolling thinckness:

-

1-3mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

DT

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

L15m*W2m*H2.2m

-

Weight:

-

15000 kg

-

Feeding width:

-

customized

-

Marketing Type:

-

Hot Product 2023

-

Thickness:

-

2mm-3mm

-

size:

-

80-150 C

-

base frame/transmission:

-

whole iron plates welded/chains

-

material:

-

Q235 carbon steel / galvanized/black strips

-

main motor + hydraulic motor power:

-

18.5 kw+ 11 kw +2.2 kw*3

-

forming station:

-

14 stations

-

forming speed:

-

20 m/min

-

shaft diameter /roller material:

-

70mm solid shafts /Gcr15 Bearing Steels with Quenching

-

electric control cabinet:

-

DELTA TOUCH SCREEN /PLC or customzied brand as clilent request

-

machine stands:

-

110 type cast iron machine stands

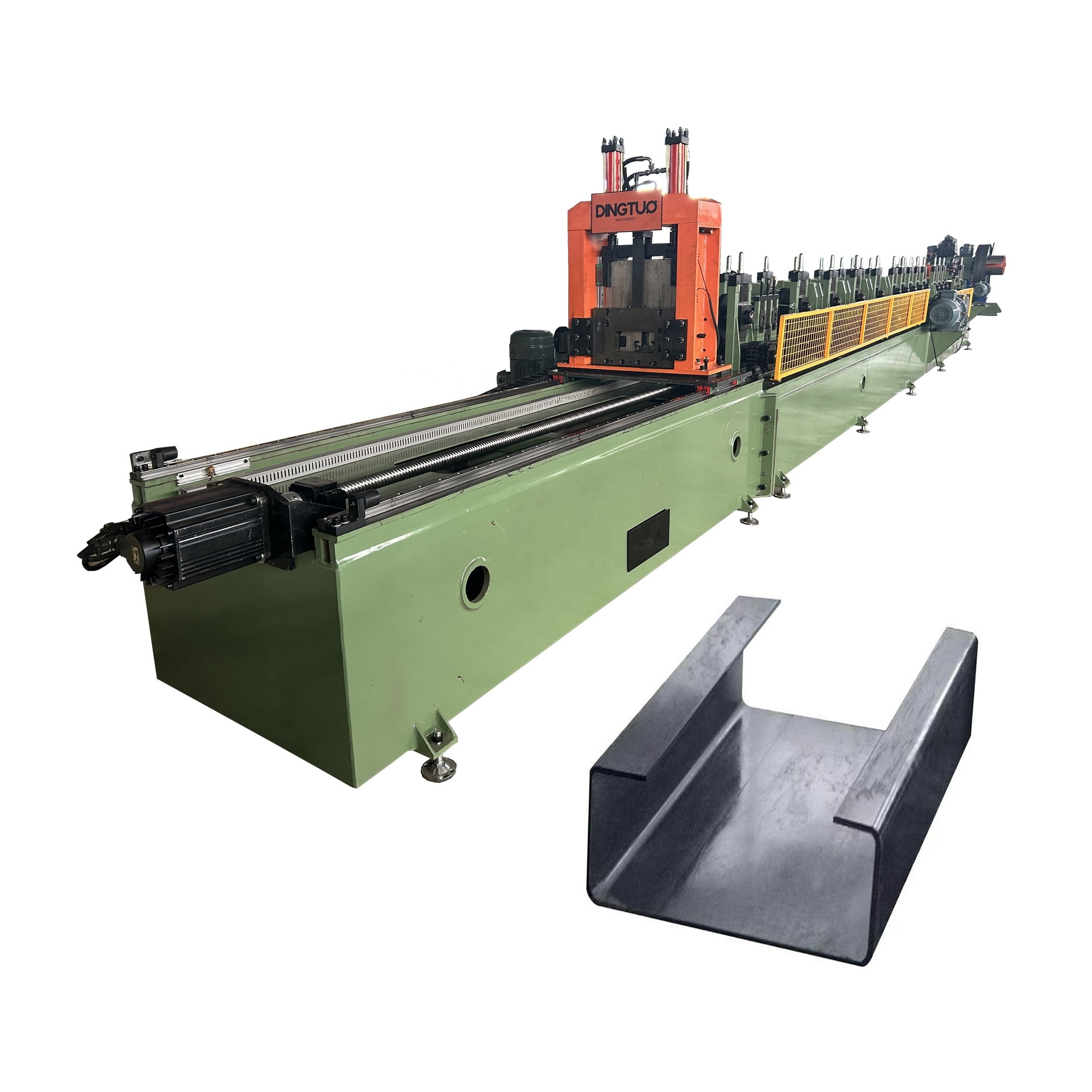

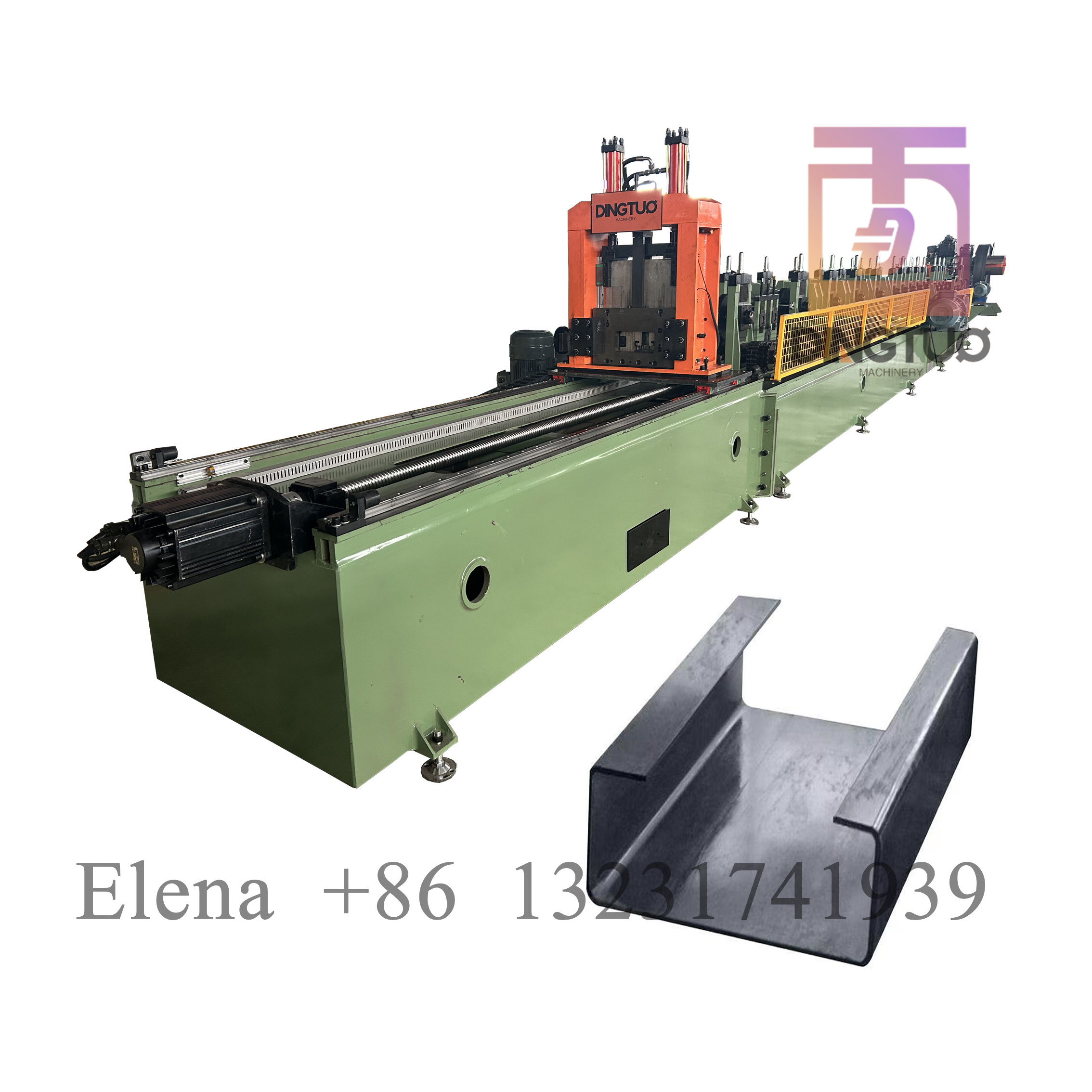

Product Overview

Cast Iron

Type

Fly Cut 80-150 C

Sections interchangeable C purlin roll forming machine

The raw materials of the C purlin cold bending forming machine are generally ordinary galvanized materials. High-strength steel galvanized materials can also be used (please tell our equipment supplier in advance about special raw material materials). Black belts can also be used (not recommended for long-term use. If the If you use black belt, please inform our equipment supplier in advance, and the machine configuration will be increased accordingly). The thickness is usually between 1.6 and 3.0mm (it can also be made with 4-6mm thickness, or other thicknesses according to customer needs. Please tell our equipment supplier in advance for special thicknesses), and the C-type cross-sectional height is between 80 and 300 mm. The Z-shaped cross-section height is between 120 and 300 mm (350-400mm height can also be customized). The raw material material, thickness, profile size, and punching size of the CZ steel machine can all be specially customized according to customer needs.

80-150 C section steel equipment is used to produce "C-shaped, Z-shaped" cold-formed steel equipment in the steel structure industry. The finished product produced by the machine is "C/Z-shaped steel (purlin)", which is mostly used to support beams and wall beams in housing construction and factories. It is commonly used in motor vehicles, railway vehicles, building doors and windows, transport vehicles, frames, switch cabinets, highway guardrails and steel structural structures, containers, steel formwork and scaffolding, shipbuilding with solar racks, bridges, transmission rods, steel sheet piles, Cable trays, agricultural machinery, furniture, warehouses, guide rails, keel steel, vegetable houses, pipe supports, municipal construction and other fields.

80-150 C section steel equipment is used to produce "C-shaped, Z-shaped" cold-formed steel equipment in the steel structure industry. The finished product produced by the machine is "C/Z-shaped steel (purlin)", which is mostly used to support beams and wall beams in housing construction and factories. It is commonly used in motor vehicles, railway vehicles, building doors and windows, transport vehicles, frames, switch cabinets, highway guardrails and steel structural structures, containers, steel formwork and scaffolding, shipbuilding with solar racks, bridges, transmission rods, steel sheet piles, Cable trays, agricultural machinery, furniture, warehouses, guide rails, keel steel, vegetable houses, pipe supports, municipal construction and other fields.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

NO. Description Quantity (set)

1 5T double head hydraulic decoiler 1

|

No

|

Item

|

Parameter

|

Note

|

|

1

|

raw material

|

galvanized steel / black strips / carbon steel

|

|

|

2

|

raw material thickness

|

1-3 mm

|

|

|

3

|

H

|

C : 80-300 mm

Z : 120-300 mm

|

can customized . If you need , welcome to connect Ms.Elena 0086-13231741939

|

|

4

|

B

|

C : 40 mm - 80 mm

Z : 50 mm - 80 mm

|

can customized . If you need , welcome to connect Ms.Elena 0086-13231741939

|

|

5

|

A

|

15 mm - 20 mm

|

can customized . If you need , welcome to connect Ms.Elena 0086-13231741939

|

|

6

|

Decoiler

|

5T box type double head high cost hydraulic decoiler

|

|

|

7

|

Pitch Shafts

|

Cast Iron Type and with one electric clutch

|

No need lift or press pitch rollers after feeding material manually

|

|

8

|

Leveling Part

|

Upper 3 and lower 4

|

|

|

9

|

Forming Shafts

|

70 mm

|

According to sheet sizes and thickness to choose the shaft diameter. Any requests , welcome to connect Ms.Elena 0086-13231741939

|

|

10

|

machine forming station

|

14

|

customzied as clients' sheet's sizes

|

|

11

|

machine stands

|

110 type cast iron machine stands equipped

|

higher cost machine stands , strong type , stable type

|

|

12

|

size changeable type

|

3 sets of size changeable servo motors , which can be changed by control panel automatically.

|

servo motor size changeable which can do stable and accurate size changeable

|

|

13

|

machine base frame

|

whole iron plates welding steel,the thickness of the table top is 30 mm,

the thickness of the side plate is 10 mm |

the whole is sanded and derusted after welding, and the table

top is processed by CNC gantry milling |

|

14

|

machine power

|

18.5 KW(main motor power)+ 11 kw ( hydraulic pump station cutting motors) + 2.2 kw *3 ( size changeable servo motor )

|

36.1 kw.h

K serious reducer which can make machine run stable

|

|

15

|

machine speed

|

20 m / min

|

we can do 20 m / min higher speed machine.Any needs , welcome to connect Ms.Elena 0086-13231741939

|

|

16

|

machine transmission way

|

2 inches chains

|

|

|

17

|

roller material

|

Gcr15 bearing # steel finishing and the surface is plated with hard chrome and polished

|

|

|

18

|

Blade material

|

Cr12 material with turning+quenching

(hardness 58-62degrees)+grinding+fine turning treatment |

|

|

19

|

Length counting method

|

OMRON (JAPAN ) brand encoder

|

|

|

20

|

Electric Control brands

|

DELTA PLC/touch screen/inverter

|

can do other brands as clients' requests

|

|

21

|

Run out table

|

1 set

|

6.1 m length . Can do automatic stacker as your needed

|

|

22

|

Voltage

|

380V,50HZ,3 Phases or customized

|

voltage can be customzied as clients' request. Any requests , welcome to connect Ms.Elena 0086-13231741939

|

|

23

|

machine size

|

L15 m * W 2 m * H 2.2 m

|

|

|

24

|

machine weight

|

15000 KGS

|

|

PRODUCT CONFIGURATION

Feeding platform & pitch shafts with e

lectric clutch

& leveling unit :

higher quality feeding platform

pitch shafts with electric clutch : no need lift or press pitch rollers after feeding material manually

Forming rollers:

14 stations ;

rollers material : Gcr15 # steel finishing and the surface is plated with hard chrome and polished;

70 mm solid shafts with 45# steel processed.

Electric control cabinet:

stand type

Delta brands or customized brands

Servo Motor Size Changeable Automatically

size changeable more accurate and stable

Cast Iron Machine Stands

110 type

stable type

Straightening

higher quality

motor :

18.5 kw K serious motor which can run the machine stable

Automatic hydraulic cutting

strong enough knife holder to ensure the cutting stability and ensure the finished products effects

C

an do various sizes

without change blades

5T double head hydraulic decoiler

Steel coil inner diameter, φ480㎜——520㎜ ㎜

Steel coil external diameter, maxφ1500 ㎜

Steel coil width 0--500 ㎜.

Bearing weight, single arm 5T, double head arm total weight 10 tons.

Application Material, SUPER GALUM, galvanized sheet, color plate, mild steel and black coils.

Machine outline size, 2830mm×1500mm×1350mm

Pneumatic material run out table

6.1 m length

Pneumatic type run out table

Product packaging

SALES AND SERVICE NETWORK

Successful Project

Project in CANADA

Project in USA

Project in UAE

RECOMMENDED PRODUCTS

EXHIBITION AND CLIENTS

SAMPLE ROOM

FAQ

1. Package

1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded by one 20ft FCL shipping.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.

2. Delivery Time

25-30 days (not include Chinese holiday) from order acceptance, deposit receipt and technical details agreement.

3. Payment

30% paid by T/T as deposit, 70% paid by T/T before loading.

4. Quality Warranty

15 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.

Free technical supporting and maintenance consulting in lifetime.

5. Assembly (Optional)

1). Machine will be tested completely in working before delivery to you.After receiving the machine and just need to connect the main power wires and can start to work. I will send you operation video , operation manual,too. very easy to operate.

2). If you need engineer overseas serviceas, the installation charge can be discuss with Elena Whastapp 0086-13231741939 If you need engineer overseas services, the buyer has to pay the seller’s technician: Travel cost outside China (Including round flight charges), accommodation and foods (At least three-star hotel with air condition), solve the language problem, provide transportation from living place to the work place, and insurance out of China, etc.

WHY CHOOSE US?

Point 1

: We are a big factory which has been developed 12 years. During the 12 years, we service each customers sincerity.

Point 2

: Our company has great engineers who can design your profile perfectly. If you want to do a better machine, the first thing is to do a better design for profiles. We are a big and old factory so we have enough experience for designing the profiles.

Point 3

: I am a very easy-going female salesperson, please tell me all your requirements for the machine, I can do my best to meet your needs. I can give you the best after-sale services. The machine is customized .So, about the machines' prices which have many .We can do your needed machine according to your request.

Point 4

: About the machines' production, we have more than 50 machine making workers in our workshop and we have more than 20 sets of CNC machines to do processing rollers, shafts, base frames , cutters......About the machine making time, we guarantee you .

Point 5

: About the machine acceptance , we can make videos and you see the machine running through videos . And also i will shoot the machine's opertaion video, connection video to you. Before machine loading, i will send you all necessary documemnts: operation video , wires connected videos, wiring diagram, floor diagram, oil circuit diagram, operation manual .....If necessary, we can send engineer to your there. No worries about the machine usage. We give you the best after-sale services.

Point 6

: The warranty time is 15 months from the machine delivery from our factory. During the period, any problems about the machine, we replace the spare parts and helping you to solve problems freely. Exceed this period, we will also solve the problems freely for you , if need to replace some spare parts, only charge the spare parts and freight for you. Solving problems through videos is free for you. We give you the best after sale services.

Point 7

:About the shipment, we have several long cooperated forwarder who can quote us the lowest sea freight . if you need us to ship for you, i can give u the best suitable sea freight . You don't need to worry about you can not deal with the shipment. Also , you can choose your own forwarder and I will cooperate with them throughout.

Hot Searches