- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1500*400*1350

-

Weight:

-

500kg

-

Warranty:

-

1 Year

-

Certification:

-

CE SGS

-

Power:

-

3KW

-

what's app:

-

8613649815817

-

skype:

-

rita-wei123

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

LX-S07

-

Brand Name:

-

LIXIN

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1500*400*1350

-

Weight:

-

500kg

-

Warranty:

-

1 Year

-

Certification:

-

CE SGS

-

Power:

-

3KW

-

what's app:

-

8613649815817

-

skype:

-

rita-wei123

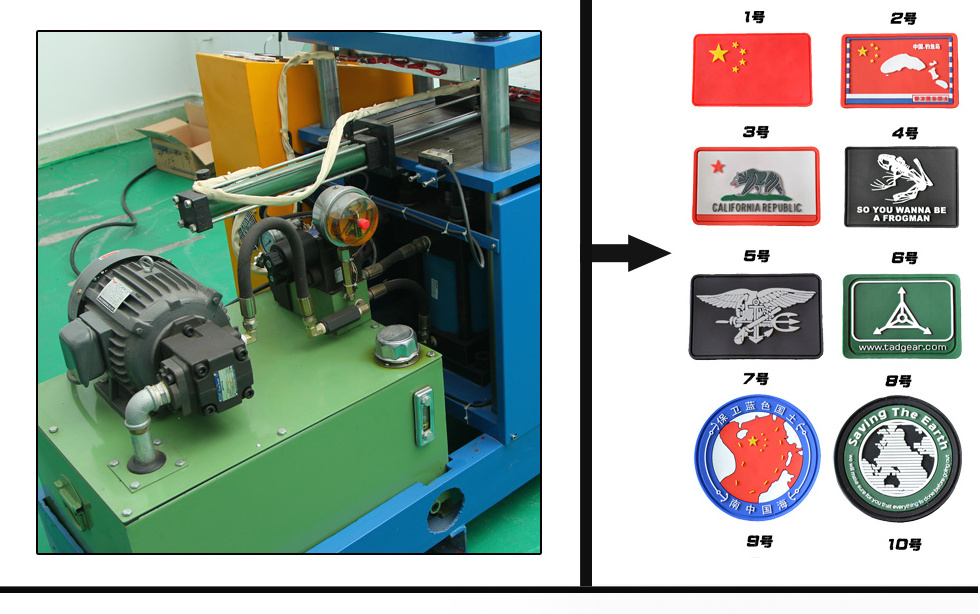

Professional Manufacture silicone rubber band printing machine

LX-S07 Solid silicone b

r

and shaping machine

After the co p per mold is cooling, put the solid silicone on to the mold, and this machine will make the raw material to be a silicone label patch.

LXS07 silicone phone case and mold making machine can be applied to various kinds of silicone product manufacturing, such as portable wristband, bangle,silicone mobile phone cover, promotional gift, debossed or embossed bracelet, food mold, accessories, Remote controller button,mat and more.

1 set of Standard Liquid Silicone Machine Specification:

|

No. of workers required |

6 persons |

|

Total area required |

20m2 |

|

Air required |

10 Hp |

|

Total Power Consumption |

380V approx. 7.5kw – 15kw 220V approx. 1.5kw |

* Could add extra machine to expand the production line

|

Code/Unit |

KN |

Heating Plate Dimension L*W (mm) |

Total Power (KW) |

Heating Power(V) |

Voltage (V) |

Weight(KG) |

Dimension L*W*H(mm) |

|

LX-S07-25 |

25 |

300*300 |

2.2 |

6 |

AC/380 |

350 |

800*1500*1200 |

|

LX-S07-50 |

50 |

380*380 |

4 |

7.5 |

AC/380 |

450 |

1000*1500*1200 |

Product Capacity of 1 set standard machine:

Approx: 3000pcs per 8 hours

*Installation:

4-5 days included (Technician fee: free of charge)

*Training( if requiring):

Short-term training or long-term training is available

(Technician fee: $2000 per month for training)

(Charge will be on monthly base, mini 1 month)

Remark :

Other working size of machine is also available.

Solid silicone brand shapping machine ,Hot pressing molding machine; Pressure film machine;

Rubber vulcanization after preheating, feeding technique of automatic discharge gas, pressure maintaining sulfide, timing alarm, automatic open mould,

Vulcanizing machine set in the products out of the mold, and other functions in one body.Adopt PLC programmable controller or manual operation according to the actual needs of users (order), record the required process and convenient operation management.

Vulcanizing machine is suitable for all kinds of rubber vulcanization, is all kinds of thermosetting plastic forming technology of advanced hot-pressing equipment.

Vulcanizing machine electric heating, steam heating and heat conduction oil heating three forms.

This machine is fully functional, compact structure, with timing clamping, automatic filling pressure, automatic temperature control, automatic timing, then alarm functions,such ashot plate surface temperature uniformity, accurate temperature control, temperature controller can accurately record the temperature data, pressure maintaining stable and reliable, safe and convenient operation etc.,use this function to ensure the product quality, production efficiency, and obtain remarkable economic Plate vulcanizing machine is suitable for sulfide (fabric) core wire rope conveyor belt.

3 performance is introduced.

1, PLC and touch screen control, which can realize manual and automatic control. Automatic control can be realized, exhaust, temperature control, curing time, alarm, and open mold unloading function; Touch screen display timely hot plate temperature of heating zone.

2, hydraulic cylinder, the ZG270-500 material, plunger using dense texture of chilled alloy cast iron, cast after fine grinding; The hydraulic cylinder for YX type sealing ring seal form.

3, hot plate adopts hydraulic automatic iron pan edge, in four cylinder under the action of hot plate on both sides of the shim and at the same time; Hot plate on both ends of the shim overlap prevention device.

4, each heating zone of hot plate is equipped with a set of temperature adjustment valve group, under the control of PLC, ensure each heating zone of hot plate temperature is uniform.

5, hydraulic system: use the well-known both at home and abroad