single station (hydraulic type, climb type ) double station ( non stop auto splicing system, non stop manual splicing system ) as option

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

custom

-

Weight:

-

25000 KG

-

Product name:

-

self adhesive sticker coating machine

-

MOQ:

-

1 set

-

Dry way:

-

Hot air

-

After Warranty Service:

-

Video technical support

Quick Details

-

Applicable Industries:

-

Other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BENYUE

-

Dimension(L*W*H):

-

custom

-

Weight:

-

25000 KG

-

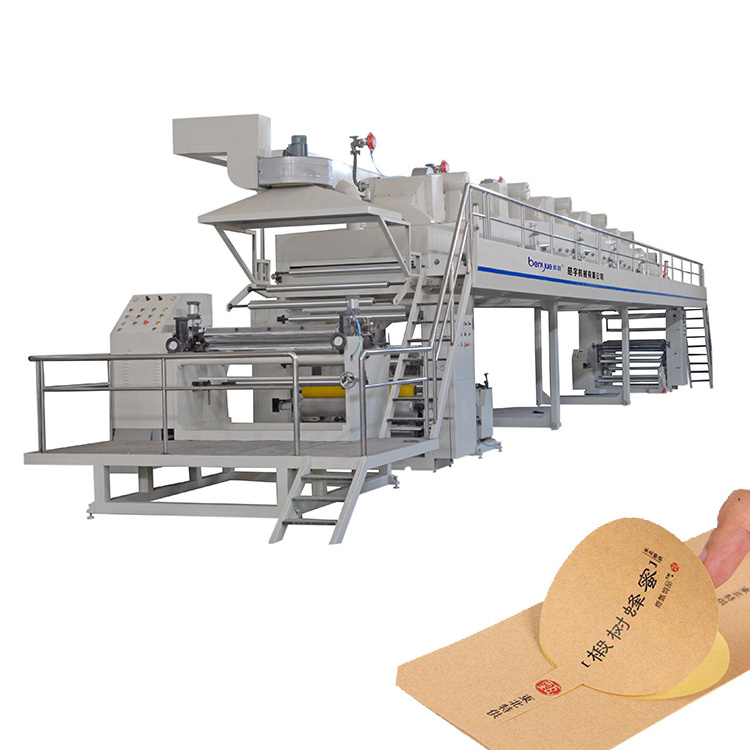

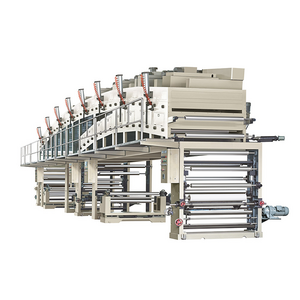

Product name:

-

self adhesive sticker coating machine

-

MOQ:

-

1 set

-

Dry way:

-

Hot air

-

After Warranty Service:

-

Video technical support

|

Model

|

TB600-2500 self adhesive sticker coating machine

|

|

Coating method

|

comma blade coating / gravure roller coating/ mayer bar coating /air knife coating / five roller coating / blade coating / slot die coating /micro gravure coating (Can be customized)

|

|

Coating width

|

600-2500MM (Can be customized)

|

|

Unwinding diameter

|

600-1500MM (Can be customized)

|

|

Winding diameter

|

600-1500MM (Can be customized)

|

|

Coating thickness

|

2-300g/square meter

|

|

Coating speed

|

10-300m / min (depending on material)

|

|

Heating method

|

Electric heating, oil heating and natural gas heating

|

Rewinding

Coating

comma blade coating / gravure roller coating/ mayer bar coating /air knife coating / five roller coating / blade coating / slot

die coating /micro gravure coating (Can be customized)

die coating /micro gravure coating (Can be customized)

Oven heating

oven heating method: electric heating, conduction oil heating, gas heating, steam heating etc can be choosed by customer

Cooling

high presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat. to reach good cooling effect.

Unwinding:

single station (hydraulic type, climb type ) double station ( non stop auto splicing system, non stop manual splicing system ) as option

Accumulator

Touch screen

Splicing table

Machine Spec.

:

1. The whole machine is controlled by 5 frequency conversion motor, and the tension (unwinding, coating, traction and winding) of the whole machine is automatically controlled by Siemens PLC system. The reliability of the tension of the whole machine is improved through the touch screen control and display of human-machine interface.

2. The discharging rack is of single station hydraulic lifting type, and magnetic powder automatic tension control is adopted.

3. The coating method of comma scraper, the clutch adjustment of comma scraper roller adopts pneumatic swing arm type, the swing arm is equipped with micro adjustment device to control, and the glue thickness is controlled by feeler gauge.

4. Moire coating method: the coating scraper shaft adopts heavy-duty double shaft mechanical independent swimming, the scraper adjustment mode is manual with pneumatic, the angle can be adjusted arbitrarily, the coating amount depends on the mesh line of the moire roller, and the different mesh lines of the moire roller can be changed for different coating amount.

5. The oven is 24 meters, the first 21 meters is divided into 7 sections, the temperature is controlled independently, the heating adopts electric heating, the hot air entering drying system, the adjustable internal circulation suction and exhaust device, the wind force of air inlet and exhaust is strong, the drying is complete, and the last 3 meters cooling box.

6. The guide wheel in the oven is synchronous with the main machine, and the drive is synchronous belt wheel drive type, which can reduce the material stretching and deformation, and make the operator easy to work.

7. The intermediate tension between coating roll and traction steel roll is synchronized by floating swing arm, which is automatically controlled by PLC

8. Automatic meter and speed counting is controlled by PLC

9. EPC ultrasonic alignment machine is used for deviation correction, so as to make the material winding neat.

10. Key type pneumatic expansion shaft with safety lock is adopted for retraction and release to facilitate loading and unloading operation.

11. High precision up pressure traction device, water circulation type is adopted for steel roll cooling, through which the film is smoother, smoother and more effective.

12. The take-up rack is a single station hydraulic lifting type.

Main Product

Customer Feedback

Hot Searches